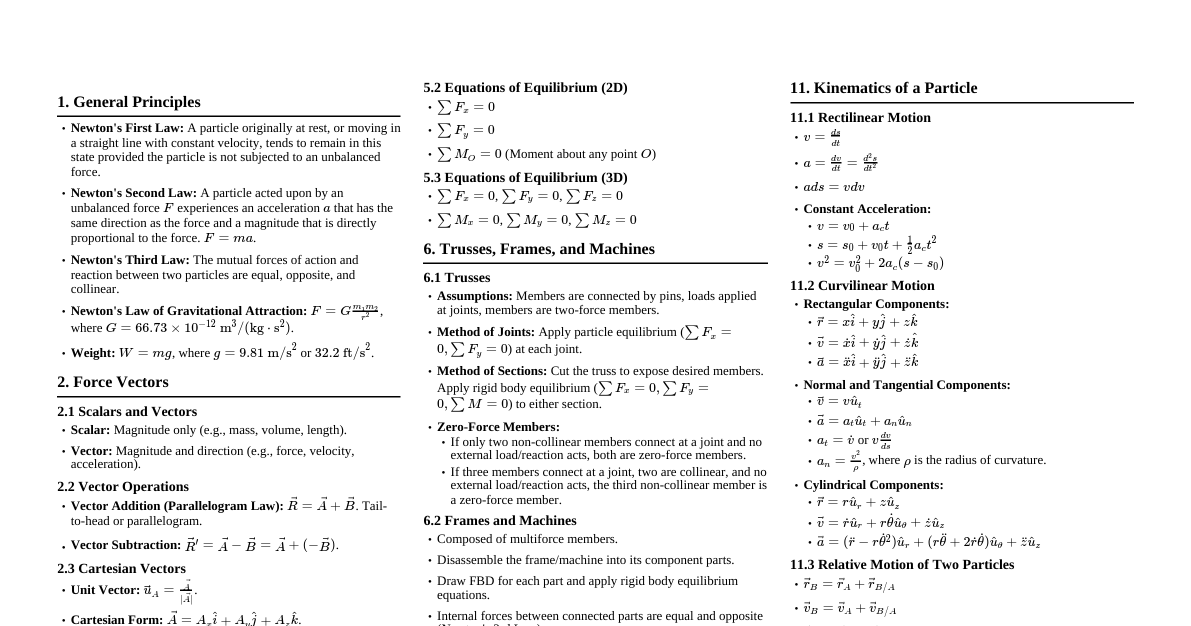

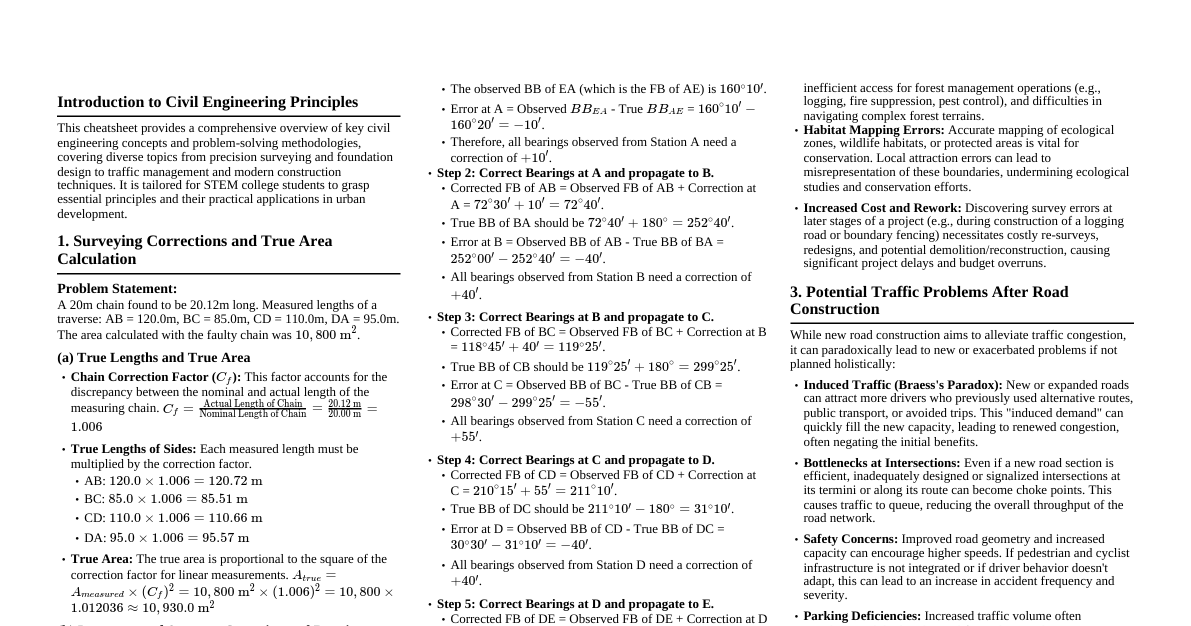

Springs Springs are devices that store mechanical potential energy. Types of Springs Helical springs Extension springs Torsion springs Compression springs Spiral springs Disk springs Leaf springs Linear springs Variable-rate springs Flat springs Power Transmission System Introduction to Drives: Mechanical power transmission is the transfer of energy from where it's generated to a place where it is used to perform work using simple machines, linkages, and mechanical power transmission elements. Reasons for Power Transmission Generated power or energy can be converted into a useful form. Physical constraints limit power generation at the place where it's used; hence, it can be transferred from source to a place where it is needed. It can be used to change direction and magnitude such as speed or torque. It can be used to change the type of energy, i.e., rotational to linear and vice versa. Rotational motion has been found to be the most ideal & simplest means of transmission of mechanical power almost with negligible losses. Rotational motion can be transmitted from one mechanical element to another with the help of certain systems called Transmission System or Drives, which may be employed to drive a device either by connecting it directly to a prime mover or the rotational motion can be transmitted to the various parts of a machine within itself. The one that drives is called the Driving system , while the other which is driven is called the Driven system . Usually, round rods called Shafts are employed to transmit the rotational motion. Types of Drives Based on distance between them, speed & power: Belt Drives Gear Drives Chain Drives Rope Drives Belt Drives Belt drives are used to transmit power or motion from one shaft to the other by means of a thin inextensible belt running over two pulleys. Driving Pulley Driven Pulley Belt Two pulleys are mounted on two different shafts. One shaft is the 'Driving shaft' which receives power, and the other is the 'Driven shaft'. The pulley on the driving shaft is the 'Driving pulley', and the other is the 'Driven pulley'. The belt passing over the pulley is kept in tension to avoid slip, transmitting power effectively. Classification of Belt Drives Based on the direction of the driving and driven shaft: Open belt drive Cross belt drive Open Belt Drive Used to connect two parallel shafts rotating in the same direction. Driving Shaft Driven Shaft Slack Side Tight Side The driving pulley pulls the belt from the lower side and delivers it to the upper side. The lower side of the belt (CD) has more tension and is known as the 'tight side'. The upper side of the belt (AB) has less tension and is known as the 'slack side'. Due to lesser tension, the belt sags on the slack side. Cross Belt Drive Used to connect two parallel shafts rotating in opposite directions. Driving Shaft Driven Shaft Tight Side Slack Side The driving pulley pulls the belt from one side (BD) and delivers it to the other side (AC). The belt side BD has more tension ('tight side'), and AC has less tension ('slack side'). Applications of Belt Drives Transmit power directly from the prime mover to any external device. Transmit rotational motion to various parts of the machine itself. Largely used for general purposes in mills & factories, especially when the distance between the two shafts is not very large. Gear Drives Gear drives are toothed wheels used to transmit considerable power over a short distance positively with a constant velocity ratio. Types of Gears Classified based on the position of the axis of the shaft: Spur gears Helical gears Bevel gears Worm gears Rack & pinion gears Spur Gears Simplest and most commonly used gears designed to transmit motion between two parallel shafts. Driving gear Shafts Driven gear The axis of the driving and driven shaft are parallel to each other. The teeth are cut straight on the circumference of the gears and are parallel to the axis. Application: Spur gears are used in machine tools, gear boxes, windup alarm clocks & watches, precision measuring instruments, etc. Helical Gears Similar to spur gears, but the teeth are curved and helical in shape. Used to transmit power between two parallel or non-parallel, non-intersecting shafts. Driving gear Shafts Driven gear Application: Compared to spur gears, helical gears are used when smooth & quiet running at higher speeds are necessary. Bevel Gears Used for transmitting power between two intersecting shafts. Driving Shaft Driven Shaft Axes of two gears Teeth are cut on conical surfaces. Usually mounted on shafts 90° apart, but can be designed for other angles. The diameter of the cone is greatest at its base, making teeth thicker there. If driving & driven gears are equal in size and axes are 90° apart, they are called 'miter gears'. Worm Gears Used to transmit power between driving & driven shafts having their axes at right angles & non-coplanar. Worm Wheel Worm Consists of a worm (a screw with helical threads) and a worm wheel (a gear with a tooth profile segment that engages with the worm). Applications: Suitable for high velocity ratios (e.g., 60:1), employed in machine tools like lathes, milling machines, drilling machines, etc. Rack & Pinion Gear Converts rotary motion into linear motion. Pinion Rack Consists of a rack (a gear with teeth cut along a straight line) and a pinion (a gear with teeth cut along its periphery). Applications: Used in machine tools such as lathes, drilling, planning machines, etc. Velocity Ratio Let $N_1$ & $N_2$ be the speed of the driving gear and driven gear respectively in r.p.m. Let $d_1$ & $d_2$ be the pitch circle diameters of the driving gear and driven gear respectively. Let $T_1$ & $T_2$ be the number of teeth on the driving gear and driven gear respectively. DRIVING GEAR SPEED = N1 DIAMETER = d1 No. of TEETH = T1 DRIVEN GEAR SPEED = N2 DIAMETER = d2 No. of TEETH = T2 Then the surface speed is: $\pi d_1 N_1 = \pi d_2 N_2$ $d_1 N_1 = d_2 N_2$ $N_2 / N_1 = d_1 / d_2$ Since the diameter of pitch circles are proportional to the circumference and the driving and driven gear work together, they must have the same pitch. The circumferences are proportional to the number of teeth in the wheels. Therefore, $N_2 / N_1 = d_1 / d_2 = T_1 / T_2$. Numerical on Velocity Ratio Numerical - 1: A simple gear drive consists of a Driving gear and Driven gear with $500 \text{ mm}$ and $250 \text{ mm}$ pitch circle diameter respectively. The driving gear rotates at $300 \text{ rpm}$. Calculate the speed of rotation of the driven gear and also velocity ratio. Solution: Given: $d_1 = 500 \text{ mm}$, $d_2 = 250 \text{ mm}$, $N_1 = 300 \text{ rpm}$. Using the velocity ratio formula: $N_2 / N_1 = d_1 / d_2$ $N_2 / 300 = 500 / 250$ $N_2 = 300 \times (500 / 250) = 300 \times 2 = 600 \text{ rpm}$. Velocity Ratio $= N_1 / N_2 = 300 / 600 = 0.5$ (or $N_2 / N_1 = 2$). Numerical - 2: A simple gear drive consists of a Driving gear $100 \text{ mm}$ of pitch circle diameter. The driving gear rotates at $200 \text{ rpm}$ and the driven gear rotates at $300 \text{ rpm}$. Calculate the diameter of the driven gear and also velocity ratio. Solution: Given: $d_1 = 100 \text{ mm}$, $N_1 = 200 \text{ rpm}$, $N_2 = 300 \text{ rpm}$. Using the velocity ratio formula: $N_2 / N_1 = d_1 / d_2$ $300 / 200 = 100 / d_2$ $1.5 = 100 / d_2$ $d_2 = 100 / 1.5 \approx 66.67 \text{ mm}$. Velocity Ratio $= N_1 / N_2 = 200 / 300 \approx 0.67$. Chain Drives Chain drive is a type of mechanical power transmission system that uses chains to transfer power from one place to another. Mechatronics Mechatronics is a branch of engineering that focuses on designing, manufacturing, and maintaining products that have both mechanical and electronic components.