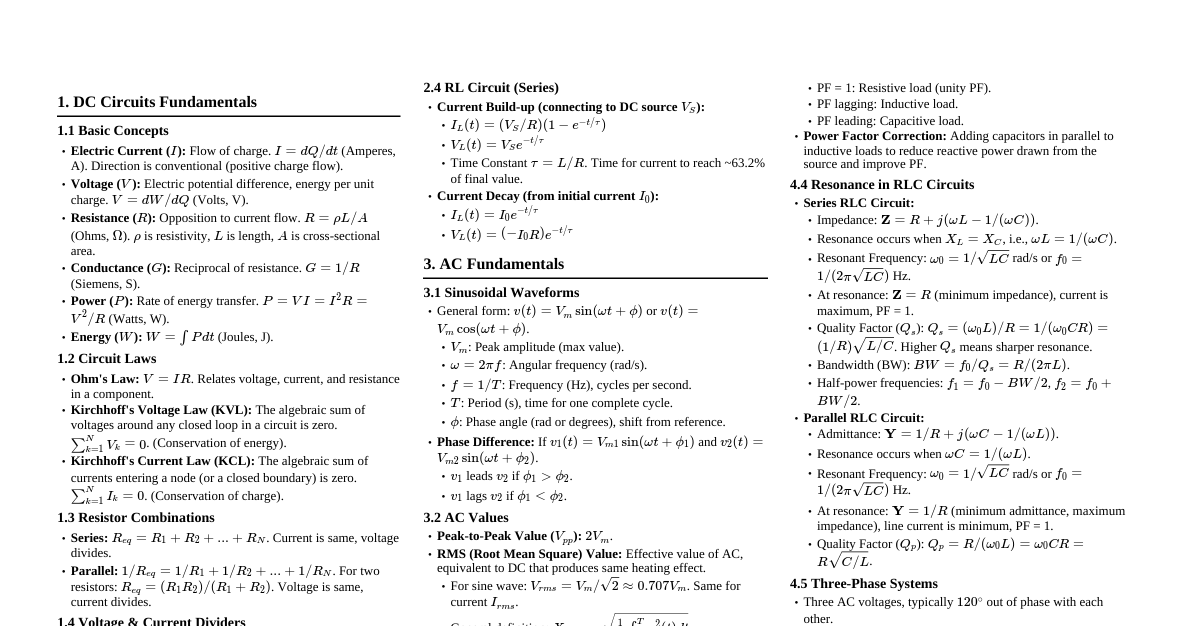

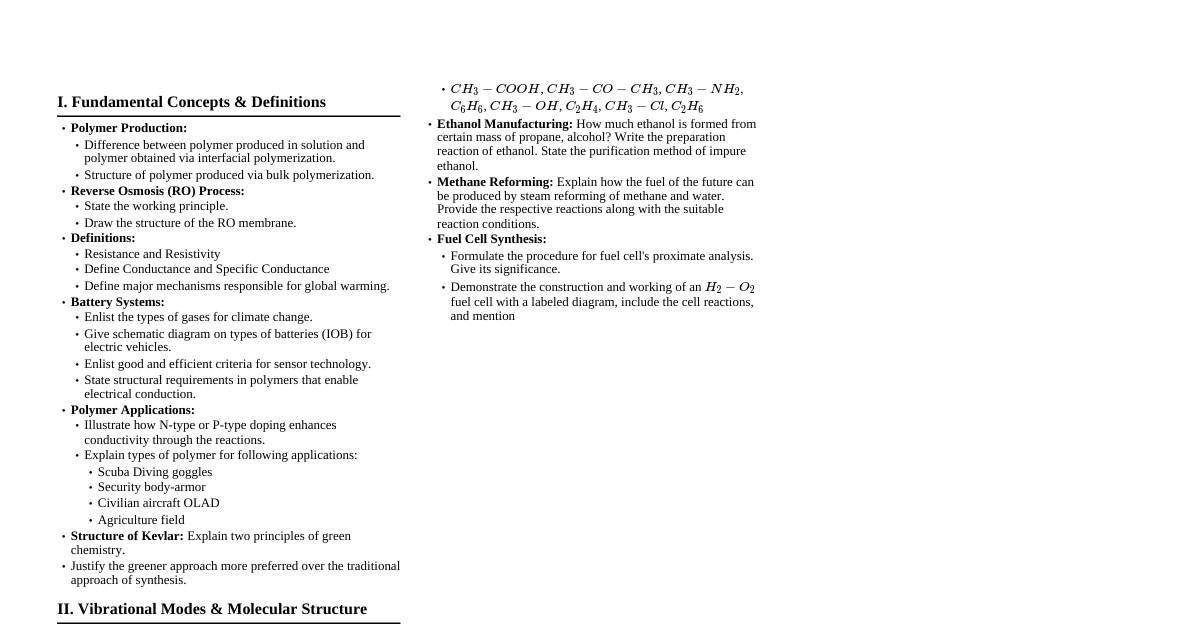

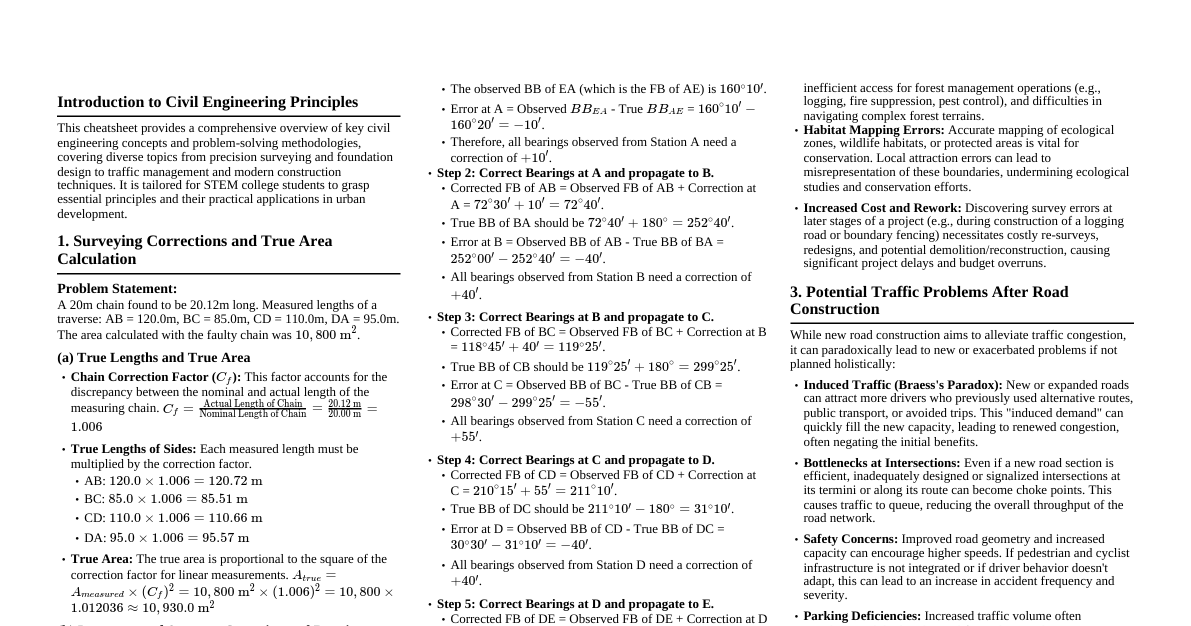

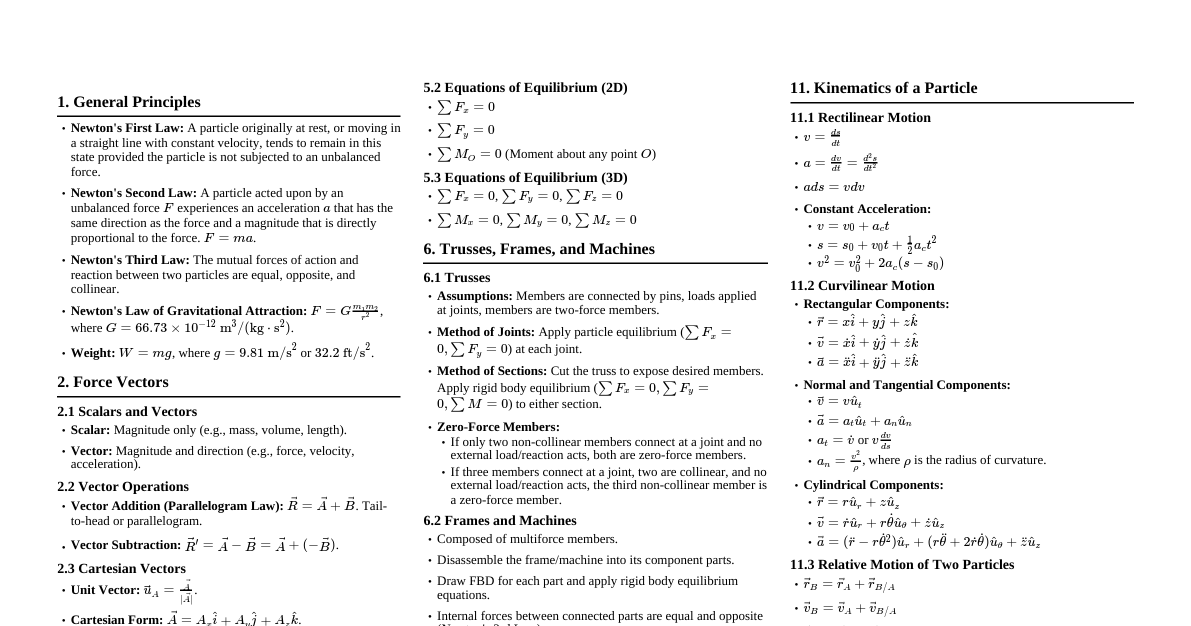

Introduction to Engineering Practice Why be an Engineer? Solve problems, create, manufacture, and improve products & processes. Apply engineering methods (math, science, measurements, calculations). Deal with costs, ethics, and uncertainty. NAE Grand Challenges of Engineering (Examples) Make solar energy economical. Provide energy from fusion. Provide access to clean water. Restore and improve urban infrastructure. Prevent nuclear terror. What Do Engineers Do? Design Engineer, Test Engineer, R&D, Quality Control, Manufacturing. Sales Engineer, Engineering Manager, New Product Development. Units and Conversions Every engineering quantity has units. Always include units. Check your units! Base Units of Measure SI US Customary Length: meter Length: foot Time: second Time: second Mass: kilogram Mass: slug Temperature: kelvin Temperature: Fahrenheit Unit Prefixes (Examples) Greater than One: Giga (G): $10^9$ Mega (M): $10^6$ Kilo (k): $10^3$ Less than One: milli (m): $10^{-3}$ micro ($\mu$): $10^{-6}$ nano (n): $10^{-9}$ Simple Unit Conversions: Factor Label Method (Dimensional Analysis) Example: Convert 300 Cubits to soccer fields. $300 \text{ cubits} \times \frac{18 \text{ inches}}{1 \text{ cubit}} \times \frac{1 \text{ foot}}{12 \text{ inches}} \times \frac{1 \text{ soccer field}}{360 \text{ feet}} = 1.25 \text{ soccer fields}$ Significant Figures (Digits) Indicates precision level. Generally work in four sig figs, round to three for final answer. Spatial Visualization (SV) Definition: Ability to mentally manipulate 2D or 3D figures; translate 2D to 3D. Importance: Important in engineering, improves GPA, calculus grades, software learning. Development: Playing with construction toys, shop/drafting classes, 3D video games, sports, strong math skills. Sketching (isometric) and physical models are best for developing SV skills. SV Evaluation Methods Mental Cutting Tests Purdue Spatial Visualization Rotation Tests 3-Dimensional Cube Test Mental Rotation Test Isometric Corner Views of Simple Objects Coded plan uses numbers to specify block stack height. Build up from the plan, showing lines only where two surfaces intersect. Object Rotations Mentally visualize object rotation in space (e.g., from X-corner view). Rules for rotation (2D or 3D): Edge in contact with axis remains in contact. Each point, edge, surface rotates by same amount. Positive = counter-clockwise; Negative = clockwise (Right-hand rule). Reflections and Symmetry Plane of Symmetry: Imaginary plane cutting an object into two reflective parts. 3D reflection differs from 2D mirror reflection; image ends up on other side of reflection plane. Project Management Definition: Temporary endeavor to create a unique product, service, or result. Project Cycle Idea Plan (feasibility, economy) Design (constructable, usable) Procure, Construct, Distribute, Operate, Dispose Successful Project Management People + Process Planning: Balancing expectations (Quality, Performance, Scale, Time, Cost). Risk Management, Project Scheduling (Gantt Chart). Prototyping & Rapid Prototyping Prototype: Early sample/model to test concepts, processes, or for replication/learning. Prototype Materials Cardboard, Paper, Balsa, Breadboard Circuit. PVC pipe, ABS, Acrylic, PolyCarbonate. Everyday items, lower-grade materials. Types of Prototypes Concept prototype, Feasibility prototype (size, functionality, strength). Production Method Test, Functional storyboard. Using Prototypes Prototype early in design process. Initial prototypes should be low cost, low commitment, fast. Test prototypes carefully (e.g., considering forces accurately). Types of Rapid Prototyping ("3D Printing") SLA - Stereolithography SLS – Selective Laser Sintering Jetted Photopolymer FDM – Fused Deposition Modeling DMLS – Direct Metal Laser Sintering Problem Solving (SOLVEM Process) Two Types of Problems: Closed Form Solution: Single, right answer (e.g., textbook problems). Open-ended: Multiple approaches, design-type (e.g., real-life problems). Both require similar steps: define problem, identify knowns/unknowns, propose solution, verify. SOLVEM Steps S = Sketch O = Observations and Objectives L = List (Assumptions and Data) V = Variables and Constants E = Equations M = Manipulate equations, variables, constants, then substitute to solve. Avoid Common Mistakes Scrambling for equations, skipping algebra, "mashing up" equations. Skipping the sketch (e.g., Free-Body Diagram for Statics, Circuit Diagram). Rushing without thinking, failing to check for 'reasonableness'. Data Collection and Representation Why Data and Graphing? Science: Discovery, Experimentation. Engineering: Quality Control, Assessment, Design, Optimization. Basic Data Collection Plan ahead. Use an engineer's field book, sketch work area. Measure twice, record neatly and accurately. Verify answers. Engineers Use Computers for: Compute and analyze, model and simulate, predict results. Handle data and graphing, control devices/instruments. Collect, store, share data, layout machinery/circuits/buildings. Types of Graphs Scatter Plot, Line Graph, Histogram, Stacked Bar Chart. Log-log for power curves ($Y = AX^B \implies \log Y = \log A + B \log X$). Semilog for exponential curves ($Y = Ae^{BX} \implies \ln Y = \ln A + BX$). Graphing Procedures Select graph paper type and grid spacing. Choose horizontal and vertical axis locations. Determine scale units (range) for each axis. Graduate and calibrate axes using the 1, 2, 5 rule. Identify each axis completely (Label, Variable symbol, Units). Plot points and use permissible symbols. Double check points that deviate from the line. Draw the curve(s). Identify each curve, add title, include notes. Darken lines for good reproduction. The 1, 2, 5 Rule: Select scale graduations so smallest division is an integer. Divide calibration by 1, 2, or 5. Engineering Estimation What is Estimation? Judging approximately the value, worth, or significance. Determining roughly the size, extent, or nature. Producing a statement of approximate cost. What is Engineering Estimation? Solving problems with no solid data. Quick calculation to approximate or verify an answer. Helps "sanity check" calculations. Fermi Method Make and state reasonable assumptions. Conduct calculations (answer should be correct order of magnitude). Revise as more accurate data is gathered. Troubleshooting Definition A logical, systematic search for the source of a problem to solve it and make a product or process operational again. Involves identifying symptoms, determining most likely cause (elimination), and confirming solution. CompTIA 6-Step Process Identify problem. Build a theory of probable cause. Test the theory to determine cause. Establish a plan to fix the problem. Check system is fully functional and prevent re-occurrence. Record findings, solutions, and results. Troubleshooting Thoughts Did it ever work? What changed? What are symptoms? Isolate parts, test with known working parts. Look for obvious issues, watch for multiple problems. Common Problems Loose connections, lack of power, loss of communications. Loose belts, friction, non-squareness, binding, crimps. Human error, short circuit, wear, poor soldering. Product Development What is a Product? An object produced by manufacturing, sold to the public. A new device, procedure, material, or method developed to solve a problem. Sources of New Product Ideas Current needs, consumer desires, new technologies/materials. Modifications of current products. Skills Needed Creativity, prototyping/modeling, understanding materials. Mechanics, electronics, packaging, marketing. Steps in Product Development Determine customer wants/needs (Features, Specifics, PRD). Define basic functions by inputs and outputs (Energy, materials, information; Subsystems). Conceptual design (Ideation, collaboration, synthesis). Biomimicry: Inspired by nature's form, function, motion. Model (CAD and math), proof of concept. Detailed design. Prototype. Test. Repeat (iterate). Good Products - Attributes Functionality, Quality at cost, Aesthetics, Durability, Reliability, Maintainability. Decision Matrix – Pugh Chart Develop many concepts, then downselect by weighting features and rating concepts. Engineering Ethics Engineering as a Profession Requires licensure, has a code of ethics. Actions can lead to loss of license or harm to the profession. Areas of Failure Associated with Engineering Negligence: Failure to exercise due care. Incompetence: Lack of ability or qualification. Misconduct: Transgression of established rules. Definitions Morals: Personal principles/standards of behavior. Ethics: Field of philosophy examining value judgments of action. Applied Ethics: Moral principles shared by a community to guide behavior. Code of Ethics: Principles, values, commitments engineers agree to. Laws: Rules established by governmental authority for order. Professional Engineering Licensure (PE) Requirements: Four-year accredited engineering degree. Pass Fundamentals of Engineering (FE) exam. Four years engineering experience under a PE. Pass Principles and Practice of Engineering (PE) exam. Maintain skills through continuing education. Engineers’ Code of Ethics - Fundamental Canons Hold paramount the safety, health, and welfare of the public. Perform services only in areas of their competence. Issue public statements only in an objective and truthful manner. Act for each employer or client as faithful agents or trustees. Avoid deceptive acts. Conduct themselves honorably, responsibly, ethically, and lawfully. RC Rock Crawlers Project Overview RC Arduino Remote 3D Printed Baja Frame Chassis Assembly Model and 3D print components Competition & Extra Credit Opportunities Lab Breakdown Prelab Sections (x6): Theory and techniques, lab intro, basic testing, component prep. Lab Sections (x5): Build Labs. Lab 6: Commissioning and Calibration. Lab 7: Competition at the Pavilion (Pickleball Courts). Grading Rubric 5% Attendance: Unexcused Absence: -1% Late to Class: -0.5% Email professor for missed classes. 20% Build Project: Full credit: Completion before next lab (all subsections signed-off). 80% credit: Completion before the following lab (n+1). 60% credit: Completed before the end of the semester. Lab grade will be the average. Lab Access RG’s Workshop: Open Lab: Monday 7-9pm Open Lab Time: Tuesdays at Noon, Tuesdays 3:00-4:20pm MEL3 C106 Hierarchy of Authority Professor Amber Johnson Lead TA (Matthew Killy, Elias Peterson, Lauren Morissette, Aubrey Silverthorne) Junior TA’s (x8) Lab Rules Wear close-toed shoes. Safety glasses (as required). Be respectful and on time. No food in lab; only closable water bottles. No outside people (Mom, SO, roommate, etc.). Music is allowed (only with headphones, appropriate volume). REMOVE EARBUDS when TA is talking. Lab 1: Inventory & Quality Control Objective: Inventory entire kit, verify no missing hardware/components/tools/3D printed parts. Deliverables: Write your name on the box lid. Complete Kit Inventory Sheet (mark missing/excess parts). Remove supports from crawler frame. Remove plastic film from remote cover plate. Assemble LEGO person. TA sign-off on grade sheet. Quality Control: System of maintaining standards by testing output against specifications. Acceptable Quality Limit: Sampling method to determine if lot meets client’s specifications. Lab 2: Component Preparation Engineering Concepts: Solder Joints: Hook vs. Lap methods. Heat Shrink: Protective electrical insulation. Crimping: Joining ductile materials by deforming them. Soldering Iron Tips: Wear safety glasses. Prepare cleaning method (wet sponge or brass). Preheat iron, clean tip often, apply new solder, wipe to shiny tip. Never leave iron on unattended. Soldering Steps: Strip wire $\sim \frac{1}{4}$", cut heat shrink $\sim \frac{1}{2}$", twist stranded wire, tin ends, insert heat shrink, solder ends, slide heat shrink over joint, shrink with heat gun. Flawless Wire Joints: Use flat edge of iron, keep iron stationary, apply gentle pressure, apply little solder to tip, apply fresh solder from other side. Crimping: JST type crimps (small wings, big wings). Deliverables: Wheel and Tire Assembly (x4 assemblies). Crimp Wires (x2 for battery housing, x2 for ESC). Gearbox Greasing and Assembly. Clearance links and shock assembly. Electrical Component preparation (Headlights, taillights, horn). Lab 3: Remote Control Soldering Part 1 Introduction to PCBs: Flat board with conductive pathways (traces) etched from copper. Remote Soldering Part 1: Apply solder paste to voltage regulator pads. Solder AMS 1117 Voltage Regulator. Solder six-pin right angle header pins and 2x 2-pin regular male header pins. Solder low-profile female header pins (2x 12-pin, 2x 2-pin, 1x 6-pin). Solder low-profile male header pins onto Arduino board (2x 12-pin, 2x 2-pin, 1x 6-pin). Solder 1x row of 8 regular male header pins to gyroscope/accelerometer. Solder gyroscope/accelerometer to PCB. Solder capacitors (smaller ones, longer wire to positive). Solder power switch (bend leads, switch pointing away from board). Solder 4 push buttons (gently straighten pins, solder from top of hole). ASTM Standard Selfie: Show selfie with physical ASTM D955-08 to TA. MSDS Read: Read Lithium-ion batteries and Lead solder MSDS, answer TA questions for sign-off. Lab 4: Remote Control Soldering Part 2 & Receiver Soldering Engineering Concepts: 3D Printed Plastic (PLA, PETG, ABS), Heat Set Inserts. Remote Soldering (Input Components): Solder six single regular male header pins for potentiometers. Bend and solder potentiometer pins to header pins. Solder RF-24 transceiver (with antenna) with threaded end facing out. Solder two toggle switches. Solder two joysticks. Solder JST female connector on the BACK of the PCB (open side towards center). Receiver Soldering: Apply solder paste, solder Voltage Regulator. Solder regular male header pins (3x 8-pins, 3x 3-pins, 2x 6-pins, 1x 2-pins). Solder two capacitors (long wire positive). Solder regular male header pins for Arduino (1x 12-pins, 1x 8-pins, 1x 6-pins, 1x 3-pins, 2x 2-pins). Directly solder Arduino board onto header pins. Solder antenna-less transceiver module. 3D Printing RC Backplate: Show successfully printed backplate (extra credit for creativity). RC Final Assembly: Heat Set Inserts: Install x6 M3 inserts into backplate using specialty tip soldering iron (220°C). Assembly: Align spacers, place cover plate, loosely thread M3x25mm bolts, tighten. Place toggle switch nuts. Install battery pack with M3x3mm counter sink screws. Plug JST plug into terminal. Lab 5: Crawler Assembly Objective: Complete the assembly of the rock crawler (electronics not plugged in, no code yet). Calibration of Servo Zero: Unpackage servo, arm, screw. Plug servo into test board (channel 1) to auto-rotate to zero position. Screw arm onto servo, facing AWAY from motor box. Steering Linkage Assembly: Fit servo casing onto steering axle (longer end facing steering linkage). Screw casing onto servo (from side opposite arm). Screw servo arm to linkage using 8mm screw. Suspension Assembly: Press fit headlights. Identify screws for suspension (M2.5x12mm, M2.5x14mm, M2.5x18mm, M2.5x22mm). Fit short straight clearance links on front axle, screw with M2.5x22mm. Repeat for rear axles with longer straight links and M2.5x18mm screws. Insert skid plate, slot M2.5x14 screws. Attach front axle to skid plate (motor to axle drive shaft, short clearance links to skid plate). Repeat for back axle. Screw bent links into skid plate (M2.5x12mm for rear, M2.5x14mm for front). Press fit M2.5 lock nuts into hex holes in rear. Screw bent clearance links and shocks into lower axles (M2.5x18mm screws). Screw top of shocks into frame (rear: M2.5x12mm into lock nuts; front: M2.5x14mm into plastic slot). Install wheels (pin, hex hub, lock nut, tighten). Electronics Installation: Press fit ESC power switch into slot, screw with M1x3mm. Press fit three M2 hex nuts, screw Arduino with x3 M2x6mm screws. Press fit brake lights. LEGO Seat (Extra Credit): Create a seat for LEGO person using M3 heat set inserts and M3x8mm screws. Lab 6: Commissioning and Calibration Objective: Fully complete Rock Crawler, learn proper use, begin data collection. Arduino Download to RC and Receiver: Refer to Prelab 6 manual for wiring and code upload instructions. Troubleshoot any connectivity issues. TA sign-off once all components are working. Calculate Speed: Experimentation: Determine speed using known distance and stopwatch. Equation: $\text{Speed} = \text{distance} \div \text{time}$. Use correct units and significant figures. Conduct multiple runs for average speed. Deliverables (Email to AmberJohnson@letu.edu): Table summary of all test runs. Highlighted fastest run. Labeled columns and displayed units. Subject in email. Intro to Competition (Lab 7): Competitions after Thanksgiving break at the pavilion. Come with battery fully charged. Baja Course: Tests maneuverability. Score based on time, deductions for cones/out of bounds. (50% attempt, 100% complete). Obstacle Course (Extra Credit): Tests power/skill on inclined platform. Speed Course: Max speed around pavilion. (80% complete, 100% for fastest time in lab group). Overview of Engineering Graphics Definition: The most effective means of communicating technical ideas and problem solutions. Engineering graphics is a language with clear, precise rules. Up to 92% of the design process is graphically based. Quick History of Engineering Graphics Early Drawing Practices: Pictograms, petroglyphs, sketches from ancient structures/machines. 14th-15th Century: Engineering drawings representing machines and buildings. Early Pioneers: Leonardo da Vinci (1452-1519): Created pictorial drawings, generally without dimensions. Leon Battista Alberti (1404-1472): Explored geometry in drawings, proposed multiple views. René Descartes (1596-1650): Inventor of Cartesian coordinate system, founder of analytic geometry. Gaspard Monge (1746-1818): Developer of descriptive geometry. Industrial Revolution: Parts produced from hand sketches, interchangeability required accurate drawings. Early Drafting Practices: Hand drawings using pencil, T-square, triangles, compasses, etc. Why Learn Sketching? Communicate concepts and ideas effectively. Applies to virtually all engineering disciplines. Teaches skills of proportion and scaling. Reflects integrity and professionalism. Alphabet of Lines The lines used in drafting, governed by ANSI Standard Y14.2M. Four distinct thicknesses: Very Thick, Thick, Medium, Thin. Visible Lines (Object Lines): Continuous lines representing visible edges and contours. Must stand out from other lines. Hidden Lines: Short-narrow dashed lines. Represent hidden features of an object. Always begin and end with a dash, unless forming a continuation of a visible line. Dimension Lines: Show extent and direction of dimensions. Terminate with an arrowhead (mechanical drawings), slash, or dot (architecture). Extension Lines: Indicate termination of a dimension. Start approx. 2-3mm from feature, extend beyond arrowhead. Usually not broken when crossing other lines. Leader Lines: Continuous straight line from note/dimension to a feature. Arrowhead touches feature; horizontal bar at note end. Should not be bent to underline note. Radial when directed to a circle/arc. Break Lines: Represent an imaginary cut in an object to view interior or fit to sheet. Thick line weight (0.5-0.6 mm). Centerlines: Thin, long and short dashes, alternately spaced. Represent axes of symmetrical parts, bolt circles, paths of motion. Every circle/arc should have two centerlines intersecting at their center. Phantom Lines: Medium-thin, long and short dashes. Represent alternate/adjacent positions, repeated details, or rough shape before machining. Starts/ends with long dash (15 mm), space (1.5 mm). Line weight 0.45 mm. Section Lines (Cross-hatching): Thin, uniformly spaced lines indicating exposed cut surfaces in a sectional view. Spacing approx. 3mm, angle 45°. Pattern determined by material. Cutting Plane Lines: Show where an imaginary cut has been made. Line type is phantom. Arrows at ends indicate line of sight. Precedence of Line Types (ANSI Standard) When lines coincide, certain ones take precedence: Visible / Feature (object) Lines Hidden (dashed) Lines Cutting Plane Lines Centerlines Break Line Dimension Lines Extension Lines / Leader Lines Section Lines / Crosshatch Lines Orthographic Projection Definition: Two-dimensional representation of a three-dimensional object. System of drawings representing different sides of an object by projecting edges perpendicular to projection planes. Six Principle Views: Created by looking straight on at the object in indicated directions. Glass Box Method: Imaginary glass box to view the six principle views. Unfold sides to create orthographic projection. First vs. Third Angle Projection Third Angle Projection: (United States) Object is between the viewer and the projection plane. First Angle Projection: (Europe and Asia) Projection plane is between the viewer and the object. Views must be arranged to align to allow interpretation. Planes Normal: Parallel to projection plane, appears true size and shape. Inclined: Perpendicular to one projection plane, angled to others. Oblique: Angled to all three principal projection planes. Cartesian Coordinate Systems 2D: XY Planes (Horizontal = X, Vertical = Y), Origin at intersection. 3D: X, Y, Z Axes. Use Right-Hand Rule for orientation. Pictorial Views Represent 3D objects on 2D paper by orienting the object to see width, height, and depth in a single view. Help visualize, assemble parts, purchase replacements. Mainly visualization aids. Axonometric Views Three types: Isometric, Dimetric, Trimetric. Created by measuring along three axes (width, depth, height). Isometric Drawing: "Equal in measure"; two receding axes tilted at 30°. Constructed with parallel, non-converging lines, in exact proportion. Vertical and angled lines relate to isometric cube axes. Circles appear as ellipses in isometric drawings. Oblique Views Quick way to sketch, represent height, width, depth. Only one receding axis, typically at 30° or 45°. Cavalier Oblique: Depth measurement transferred directly to receding axis. Can appear exaggerated. Cabinet Oblique: Distances along receding axis reduced by half to lessen exaggeration. Curved edges appearing circular in front face can be transferred directly. Perspective Sketch Most realistic-looking view, like a photograph. Portions farther away are smaller, lines recede into distance. Multi-View Drawings Standard: 3-view (Front, Top, Right side). Combination of views must clearly, correctly, concisely convey all part details. Types of Views One or Two View Drawing: Used when sufficient to accurately depict part (e.g., cylindrical, sheet metal). Section View: Clarifies interior features not clearly seen by hidden lines. Section lines can identify material. Detail View: Depicts a portion of the part at a larger scale. Break or Broken View: Depicts large uniform item at larger scale by removing portions with break lines. Broken Out View: Material removed to specified depth to expose inner details. Auxiliary View: Depicts an oblique or inclined plane with true dimensions. Dimensioning and Tolerancing ASME/ANSI Y14.5 Standard is key for dimensioning and tolerancing. Part Dimensioning Goal Clear, concise dimensions for manufacturing and inspection. Add reference dimensions and notes as needed. Do NOT over-dimension (each feature once). Place dimensions in most descriptive view, outside object boundaries. Do not cross dimension lines or leaders. Align and group. General Dimensioning Practices Dimensions of Size: Height, Width, Depth, diameter, etc. Dimensions for Location: Where it is in space (X, Y, Z). Angles: Indicated by '°' symbol. Holes: Diameter and location in circular view. Cylindrical Parts: Can often be represented in one-view with $\emptyset$ diameter symbol. Arcs: Dimensioned by radius, preceded by 'R'. Avoid placing dimensions on the object itself. Tolerance Definition: Indication of limits of accuracy for a part's dimensions. Impossible to manufacture parts without variation. Limits act as quality control. Specify accuracy required for function; avoid unnecessary accuracy (cost). Dimensional Tolerance Types Limit: Maximum and minimum size a part can obtain and pass inspection. Unilateral: Total tolerance in one direction only (+ or -). Bilateral: Dimension may vary in both directions (+ and -) from nominal size. Plus and Minus (Title Block): Applies to all dimensions not covered by other tolerancing. Tolerance Definitions Maximum Material Condition (MMC): Size of part with most material (e.g., largest shaft, smallest hole). Least Material Condition (LMC): Size of part with least material (e.g., smallest shaft, largest hole). Maximum Clearance: LMC Hole - LMC Shaft Minimum Clearance (Allowance): MMC Hole - MMC Shaft Tolerance Accumulation Tolerance between features depends on number of controlling dimensions. Max variation = sum of tolerances on controlling dimensions. Increases with more controlling dimensions. Types of Fits General range of tightness from allowance and tolerances. Clearance Fit: Always a space; Min. Clearance > 0. Interference Fit: Never a space; Max. Clearance $\le$ 0. Transition Fit: May or may not be a space; Max. Clearance > 0, Min. Clearance Line Fit: Space or contact; Max. Clearance > 0, Min. Clearance = 0. Geometric Dimensioning and Tolerancing (GD&T) System of symbols, rules, definitions for shape (Roundness, Flatness) and design intent (parallel, perpendicular). Objectives: Define parts by function, include geometric/size tolerances, facilitate inspection, reduce notes. Material Condition Symbols M: Maximum Material Condition (MMC) L: Least Material Condition (LMC) S: Regardless of Feature Size (RFS) Form Controls Straightness: Feature must be within tolerance of size and between two parallel planes. Flatness: Surface within tolerance of size, between two parallel planes. Roundness: Circular element within tolerance of size, between two concentric circles. Cylindricity: Cylindrical surface within tolerance of size, between two concentric cylinders. Orientation Controls Perpendicularity Parallelism Angularity Line Profile Surface Profile Location Controls Position Concentricity Runout Orthogonal Datum Planes "3-2-1" Rule Defines minimum contact points to locate a part: Primary Datum: 3 points Secondary Datum: 2 points Tertiary Datum: 1 point GD&T controls shape and initial design intent, unlike dimension tolerance alone. Working Drawings Complete set of standardized drawings for manufacture and assembly of a product. Must: Describe parts (visual/dimensional), show assembly, identify parts, specify standard parts. Typically include: Detail drawings, assembly/subassembly drawings, Bill of Materials (BOM), Title Block. Detail Drawings Dimensioned, multiview drawing of a single part. Describes part's shape, size, material, finish. Enough info to manufacture part from drawing alone. Assembly Drawings Shows how each part of a design is put together. Includes: All parts in operating position, parts list (BOM), labels for standard/nonstandard parts. Sectioned assemblies give general graphic description of interior. Normally do NOT display dimensions (main task is to locate and provide info on components). Design for the Assembly Minimize components, product/component variation. Use assembly-oriented construction principles. Bottom-up Method: Design/model parts first, then assemble and mate. Top-down Method: Design parts' shapes, sizes, locations within the assembly context. Use sub-assemblies. Use a fixed base component or sub-assembly. Design for ease of insertion, fastening, handling, etc. Design for interference and collision detection.