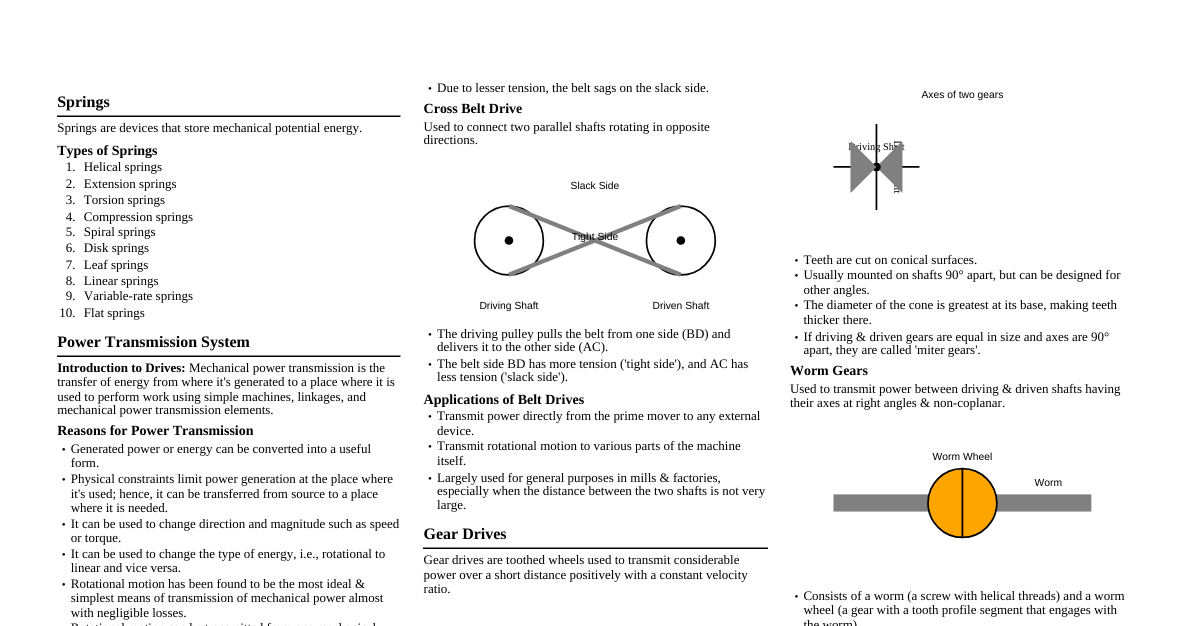

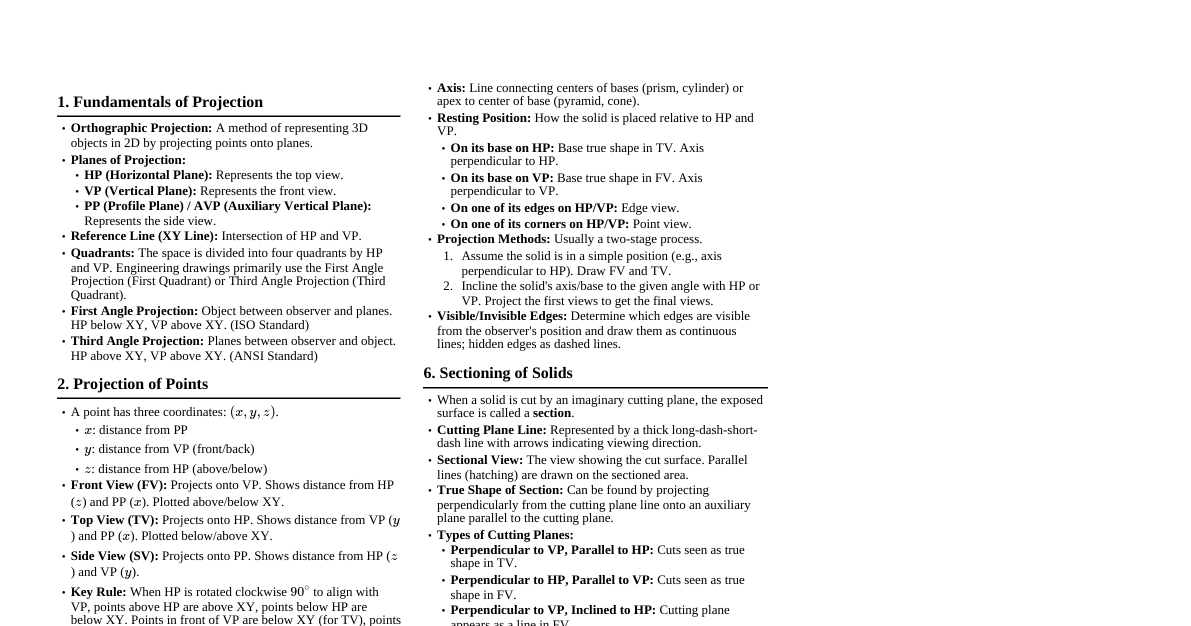

Springs: Introduction & Functions Definition: Mechanical device storing and releasing energy when deflected. Material: Commonly made of music wire, hard-drawn wire, or oil-tempered wire. Key Functions: Absorb shock and vibration Store energy Measure force Apply force and control motion Types of Springs Wire Springs: Helical (compression, extension, torsion), Conical, Volute. Flat Springs: Leaf springs, Belleville washers, Flat spiral, Cantilever, Clock-type. Special Shaped Springs: e.g., Garter springs, Disc springs. Helical Compression Springs Purpose: Resists compressive forces, stores energy when compressed. Shape: Open-coiled helical spring. Ends: Plain End Plain & Ground End Squared End Squared & Ground End (most common for stability) Drawing Representation: Detailed View: Shows individual coils, wire diameter ($d$), mean coil diameter ($D$), pitch ($p$), free length ($L_f$), solid length ($L_s$). Simplified View: Often represented by two parallel lines with diagonal crosses or zig-zags. Helical Extension Springs Purpose: Resists tensile forces, stores energy when stretched. Shape: Close-coiled helical spring. Ends: Various hook designs (e.g., machine hooks, cross-over center hooks, extended hooks) to attach to components. Drawing Representation: Similar to compression springs but with hooks at the ends. Simplified: Parallel lines with hooks. Helical Torsion Springs Purpose: Exerts a torque or rotary force. Shape: Helical spring designed to operate over a shaft or arbor. Ends: Straight tangential legs, often bent or formed for specific attachment points. Drawing Representation: Shows the helical body and the specific shape of the end legs. Simplified: Helical shape with bent ends indicating torsion action. Leaf Springs (Multi-leaf or Semi-elliptic) Purpose: Absorb shocks, primarily in vehicle suspension systems. Construction: Consists of several leaves of varying lengths, stacked together and held by a center bolt and U-bolts. Master Leaf: Longest leaf, often with eyes at the ends for attachment. Drawing Representation: Shows the layered structure of the leaves, master leaf, and clamping elements. Simplified: Stacked arcs. Belleville Springs (Conical/Disc Springs) Purpose: Provide high load capacity in small spaces, often used in stacks for variable spring rates. Shape: Conical disc or washer shape. Drawing Representation: Shows the conical profile. Can be stacked in series (for more deflection) or parallel (for more load). Spiral Springs (Flat Spiral) Purpose: Store and release rotational energy, used in clocks, toys, etc. Shape: Flat strip of metal wound into a spiral. Drawing Representation: Shows the coiled flat strip with inner and outer attachment points. Drawing Conventions & Details Sectioning: Helical springs are often sectioned to show wire diameter and coil details. A section plane is indicated. Dimensioning: Wire diameter ($d$) Mean coil diameter ($D$) or Outer/Inner diameter Number of active coils ($N_a$) Total coils ($N_t$) (for compression springs, including inactive coils) Pitch ($p$) Free length ($L_f$) Solid length ($L_s = N_t \times d$) (for compression springs) Length of body (for extension/torsion springs) Hook dimensions (for extension springs) Leg angles/lengths (for torsion springs) Simplified vs. Detailed Drawings: Detailed: For manufacturing, showing all geometry. Simplified: For assembly drawings or schematic representations, focusing on function and position. Assembly Context: Always consider how the spring interacts with other components; show mating parts in assembly drawings. Important Idea for Machine Drawing Clarity is Key: Ensure all dimensions, tolerances, and material specifications are clearly indicated. Standard Representations: Utilize simplified representations where appropriate to avoid clutter, but ensure they are unambiguous. Functionality: The drawing should convey not just the form but also the intended function of the spring within the assembly. For example, for a compression spring, showing its free length and compressed length under load (if specified). End Conditions: Pay close attention to how spring ends are treated (ground, squared, hooked, looped) as they are crucial for mounting and performance. Material Specification: Always specify the spring material (e.g., ASTM A228 music wire) and any surface treatments (e.g., shot peening, plating). Spring Rate: While not always explicitly drawn, understanding spring rate (force per unit deflection) helps in dimensioning for functionality. $k = \frac{Fd^4}{8D^3N_a}$ (for helical springs).