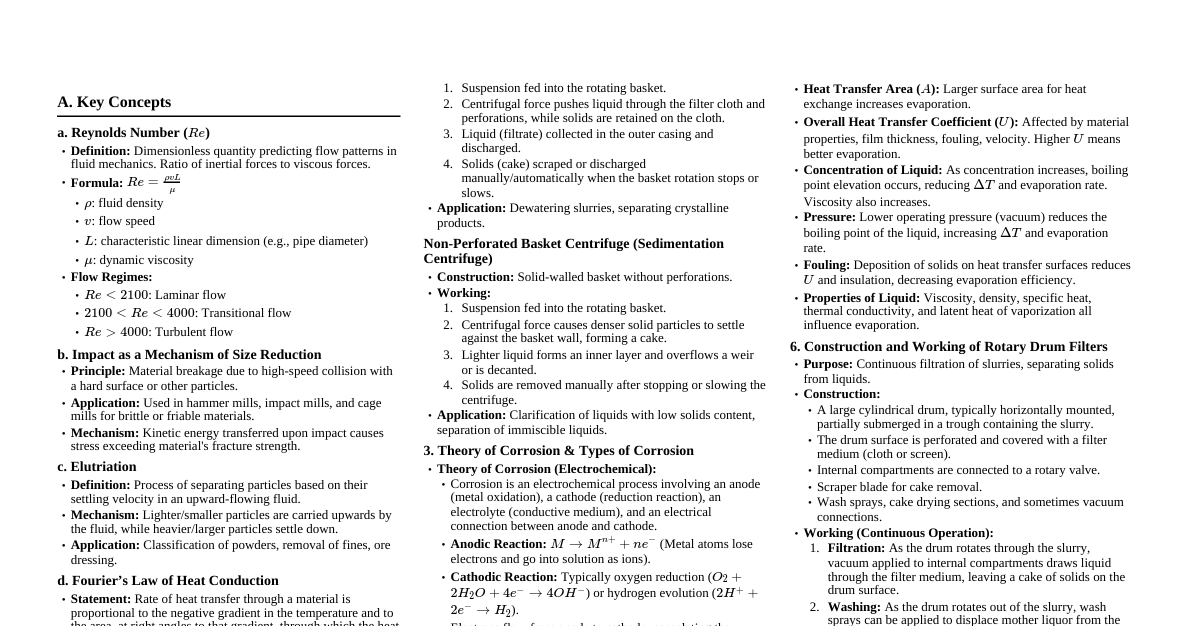

### Flow of Fluids #### Types of Manometers Manometers are devices used to measure pressure differences. - **Simple Manometer:** Consists of a U-tube containing a liquid (e.g., mercury, water). Pressure difference is indicated by the height difference of the liquid columns. - **Piezometer:** Measures gauge pressure of liquids. Open to atmosphere, measures positive pressures. - **U-tube Manometer:** Measures positive, negative, or differential pressures. Can use different fluids based on pressure range. - **Single Column Manometer:** One reservoir, one tube. More sensitive than U-tube manometers. - **Differential Manometer:** Measures the difference in pressure between two points. - **U-tube Differential Manometer:** Connects two points in a fluid system. - **Inverted Differential Manometer:** Used for measuring small pressure differences, especially for gases. - **Inclined Manometer:** U-tube with one leg inclined. Increases sensitivity for small pressure differences. - **Micromanometer:** Highly sensitive for very small pressure differences. #### Reynolds Number and its Significance The Reynolds number (Re) is a dimensionless quantity that helps predict flow patterns in different fluid flow situations. $$Re = \frac{\rho v D}{\mu} = \frac{v D}{\nu}$$ Where: - $\rho$ = fluid density (kg/m³) - $v$ = flow velocity (m/s) - $D$ = characteristic linear dimension (e.g., pipe diameter) (m) - $\mu$ = dynamic viscosity of the fluid (Pa·s or N·s/m²) - $\nu$ = kinematic viscosity ($\mu/\rho$) (m²/s) **Significance:** - **Laminar Flow (Re 4000 for pipes):** Fluid particles move in chaotic, irregular paths, causing rapid mixing. High velocity, low viscosity. - **Design of equipment:** Helps in designing pipes, pumps, and other fluid handling equipment to ensure efficient flow and prevent energy losses. - **Heat and Mass Transfer:** Turbulent flow enhances heat and mass transfer due to increased mixing. #### Bernoulli’s Theorem and its Applications Bernoulli's theorem states that for an incompressible, non-viscous fluid in steady flow, the total mechanical energy along a streamline is constant. $$P + \frac{1}{2}\rho v^2 + \rho g h = \text{constant}$$ Where: - $P$ = static pressure of the fluid (Pa) - $\frac{1}{2}\rho v^2$ = dynamic pressure (Pa) - $\rho g h$ = hydrostatic pressure (Pa) - $P/\rho g$ = pressure head (m) - $v^2/2g$ = velocity head (m) - $h$ = elevation head (m) **Applications:** - **Venturi Meter:** Measures the flow rate of an incompressible fluid. Based on the principle that as fluid velocity increases, pressure decreases. - **Orifice Meter:** Similar to a Venturi meter, but uses an orifice plate to create a pressure drop. Simpler, but less accurate. - **Pitot Tube:** Measures fluid velocity. Relates the difference between stagnation pressure and static pressure to fluid velocity. - **Pumps and Turbines:** Used in the design and analysis of fluid machinery. - **Aircraft Wings (Aerofoil):** The shape of an aircraft wing creates a pressure difference, generating lift. #### Energy Losses in Fluid Flow Energy losses occur due to friction and other factors as fluid flows through pipes and fittings. - **Major Losses (Friction Losses):** Due to friction between the fluid and the pipe wall, and between fluid layers. Calculated using the Darcy-Weisbach equation: $$h_f = f \frac{L}{D} \frac{v^2}{2g}$$ Where: - $h_f$ = head loss due to friction (m) - $f$ = Darcy friction factor (dimensionless) - $L$ = length of the pipe (m) - $D$ = diameter of the pipe (m) - $v$ = average velocity of the fluid (m/s) - $g$ = acceleration due to gravity (m/s²) - For laminar flow, $f = 64/Re$. For turbulent flow, $f$ depends on Re and relative roughness (Moody chart). - **Minor Losses (Form Losses):** Due to changes in pipe geometry, such as sudden expansion/contraction, bends, valves, and fittings. These cause local turbulence and energy dissipation. $$h_m = K \frac{v^2}{2g}$$ Where: - $h_m$ = minor head loss (m) - $K$ = loss coefficient (dimensionless, specific to each fitting) - $v$ = average velocity (m/s) - $g$ = acceleration due to gravity (m/s²) - **Examples:** Entrance and exit losses, sudden contraction/expansion, elbows, tees, valves. ### Size Reduction #### Objectives of Size Reduction Size reduction (comminution) is the process of reducing large solid particles into smaller ones. - **Increase Surface Area:** Crucial for dissolution, extraction, drying, and chemical reactions. - **Improve Mixing and Blending:** Smaller particles mix more uniformly, ensuring homogeneity of products. - **Enhance Dissolution Rate:** For sparingly soluble drugs, smaller particles dissolve faster, improving bioavailability. - **Improve Flow Properties:** Can make powders flow more freely or, in some cases, less freely (e.g., very fine powders). - **Facilitate Extraction:** Breaks down cell walls, allowing better solvent penetration for extraction processes. - **Aid in Drying:** Increased surface area accelerates moisture removal. - **Achieve Uniform Particle Size Distribution:** Important for consistent dosage and performance. - **Separate Undesirable Components:** Can sometimes be used to separate impurities. - **Improve Handling:** Easier to handle and transport smaller particles. #### Mechanisms of Size Reduction - **Impact:** Material is hit by a rapidly moving object (e.g., hammer mill). Causes shattering. - **Attrition:** Material is subjected to rubbing or scraping between two surfaces (e.g., fluid energy mill, roller mill). Produces fine powders. - **Compression:** Material is crushed between two surfaces (e.g., jaw crusher, roller mill). Effective for brittle materials. - **Cutting:** Material is cut by a sharp blade (e.g., cutter mill). Used for fibrous materials. - **Shearing:** Applies stress parallel to a surface, causing layers to slide past each other. #### Laws Governing Size Reduction These laws relate the energy input required for size reduction to the change in particle size. - **Rittinger's Law:** States that the energy required for size reduction is directly proportional to the new surface area created. $$E = K_R (S_2 - S_1)$$ Where: - $E$ = energy input - $K_R$ = Rittinger's constant - $S_1$, $S_2$ = initial and final surface areas - Applicable to materials reduced to very fine sizes, where surface energy is dominant. - **Kick's Law:** States that the energy required is proportional to the ratio of the change in size to the original size. $$E = K_K \ln \left( \frac{L_1}{L_2} \right)$$ Where: - $E$ = energy input - $K_K$ = Kick's constant - $L_1$, $L_2$ = initial and final characteristic lengths - Applicable to coarse crushing, where elastic deformation is dominant. - **Bond's Law:** States that the energy required is proportional to the new crack length produced, or inversely proportional to the square root of the product particle diameter. $$E = K_B \left( \frac{1}{\sqrt{P}} - \frac{1}{\sqrt{F}} \right)$$ Where: - $E$ = energy input - $K_B$ = Bond's work index - $P$ = product particle size (80% passing) - $F$ = feed particle size (80% passing) - Most widely used law, applicable to intermediate-range size reduction. #### Factors Affecting Size Reduction - **Hardness:** Harder materials require more energy and different mechanisms. - **Toughness/Brittleness:** Brittle materials shatter easily (impact, compression). Tough/fibrous materials require cutting/shearing. - **Abrasiveness:** Abrasive materials cause wear on mill parts. - **Stickiness/Moisture Content:** Sticky materials can clog mills. Moisture content can affect friability. - **Softening Point:** Materials with low softening points can melt or become gummy during reduction due to heat generation. - **Particle Size of Feed:** Determines the type of mill suitable. - **Desired Particle Size of Product:** Influences the choice of mill and operating conditions. - **Material Structure:** Crystalline vs. amorphous. - **Safety:** Dust explosion risk, toxicity. ### Size Separation #### Objectives of Size Separation Size separation (sizing, screening, classification) is the process of separating a mixture of particles into two or more fractions based on their size. - **Improve Product Quality:** Ensures uniformity of particle size, important for dosage forms, flowability, and dissolution. - **Remove Fines or Oversize Particles:** Eliminate undesirable particles that may cause processing issues or affect product performance. - **Facilitate Downstream Processing:** Properly sized particles are easier to handle, mix, and compress. - **Increase Efficiency of Other Operations:** For example, removing fines before crushing can improve crusher efficiency. - **Recover Valuable Material:** Separation can isolate specific size fractions for different applications. - **Dust Control:** Removing very fine particles can reduce dust hazards. - **Quality Control:** Ensures that raw materials and finished products meet specifications. #### Applications of Size Separation - **Pharmaceutical Industry:** - **Granulation:** Separating granules by size to ensure uniform tablet compression. - **Powder Blending:** Ensuring component powders are of suitable size for uniform mixing. - **Capsule Filling:** Optimizing particle size for consistent fill weight. - **Suspensions/Emulsions:** Ensuring particle size for stability and redispersibility. - **API Production:** Separating desired crystal sizes. - **Food Industry:** Separating flour, spices, sugar. - **Chemical Industry:** Separating catalysts, pigments. - **Mining Industry:** Separating ores. - **Construction Industry:** Sizing aggregates. #### Mechanism of Size Separation Size separation typically involves passing particles through openings of a defined size. - **Screening/Sieving:** Most common method. Particles are presented to a screen (sieve) with specific mesh openings. - **Undersize particles:** Pass through the openings. - **Oversize particles:** Retained on the screen. - **Mechanism:** Agitation (shaking, vibrating, rotating) is applied to encourage particles to find openings. Gravity also plays a role. - **Sedimentation/Classification:** Utilizes differences in settling velocities of particles in a fluid (liquid or air). - **Mechanism:** Larger, denser particles settle faster than smaller, less dense particles. Used in cyclones, elutriators, and sedimenters. - **Centrifugal Separation:** Uses centrifugal force to separate particles based on size and density. - **Mechanism:** Particles are spun, and heavier/larger particles move outwards, while lighter/smaller particles remain closer to the center. Used in cyclones and centrifuges. #### Official Standards of Powders Pharmacopoeias (e.g., USP, BP, IP) define official standards for powders based on their fineness, which is determined by sieving. - **Coarse Powder:** All particles pass through a No. 20 sieve, and not more than 40% pass through a No. 60 sieve. - **Moderately Coarse Powder:** All particles pass through a No. 40 sieve, and not more than 40% pass through a No. 80 sieve. - **Fine Powder:** All particles pass through a No. 80 sieve. - **Very Fine Powder:** All particles pass through a No. 120 sieve. - **Colloidal Particles:** Particles generally below 1 µm, not typically separated by sieving. #### Sieves Sieves are devices with uniform openings used to separate particles by size. - **Construction:** Typically made of wire mesh (woven from brass, bronze, stainless steel) or perforated metal plates. - **Mesh Number:** Refers to the number of openings per linear inch. A higher mesh number means smaller openings. - **Sieve Aperture (Opening Size):** The nominal distance between adjacent wires. This is the critical dimension for particle separation. - **Standard Sieves:** Specified by pharmacopoeias (e.g., ASTM E11, ISO 3310-1) to ensure consistency in particle size analysis. - **Sieve Shakers:** Mechanical devices that provide agitation (shaking, tapping, vibrating) to facilitate particle passage through sieves. #### Principles of Size Separation - **Probability of Passage:** A particle will pass through a sieve opening if its dimensions are smaller than the opening, and it presents itself to the opening in a favorable orientation. - **Particle Shape:** Irregularly shaped particles (e.g., elongated) may pass through an opening larger than their smallest dimension or be retained on a sieve even if their overall volume suggests they should pass. - **Particle Size Distribution:** A mixture of particles will have a range of sizes. Size separation aims to divide this distribution into distinct fractions. - **Efficiency of Separation:** Never 100%. Some undersize particles may be retained, and some oversize particles may pass through (due to imperfections, blinding, or particle orientation). - **Blinding:** Clogging of sieve openings by particles that are just slightly smaller than the opening size, reducing efficiency. - **Electrostatic Charges:** Can cause particles to stick to each other or to the sieve, hindering separation. - **Moisture Content:** Can cause particles to agglomerate or stick to the sieve. ### Heat Transfer #### Objectives of Heat Transfer Heat transfer is the movement of thermal energy from a region of higher temperature to a region of lower temperature. - **Temperature Control:** Maintaining desired temperatures for processes (e.g., reaction temperatures, storage conditions). - **Heating/Cooling:** Adding or removing heat from materials or systems (e.g., sterilization, drying, refrigeration). - **Evaporation/Condensation:** Phase change operations that rely on heat transfer. - **Sterilization/Pasteurization:** Destroying microorganisms through controlled heating. - **Drying:** Removing moisture by supplying heat. - **Distillation:** Separating components based on boiling points, requiring heat input and removal. - **Energy Conservation:** Designing efficient heat exchangers to minimize energy waste. - **Process Optimization:** Ensuring uniform temperature distribution for consistent product quality. #### Applications of Heat Transfer - **Pharmaceutical Manufacturing:** - **Sterilization:** Autoclaves, hot air ovens. - **Drying:** Tray dryers, fluid bed dryers, spray dryers. - **Evaporation:** Concentrating solutions (e.g., extracts). - **Distillation:** Purifying solvents, separating liquids. - **Reaction Control:** Maintaining exothermic/endothermic reaction temperatures. - **Formulation:** Cooling ointments, suppositories. - **Food Processing:** Cooking, refrigeration, pasteurization. - **Chemical Industry:** Reactors, distillation columns, heat exchangers. - **Power Generation:** Boilers, condensers in power plants. - **HVAC Systems:** Heating, ventilation, air conditioning. #### Heat Transfer Mechanisms There are three primary modes of heat transfer: - **Conduction:** Transfer of heat through direct contact between particles, without macroscopic movement of the material itself. - **Mechanism:** Occurs in solids, liquids, and gases. In solids, heat is transferred by vibration of molecules and free electron movement. In liquids and gases, by molecular collisions. - **Example:** Heating a metal rod, heat passing through a pipe wall. - **Convection:** Transfer of heat through the movement of fluids (liquids or gases). - **Mechanism:** Involves the actual movement of heated fluid particles. - **Natural Convection:** Fluid movement is caused by density differences arising from temperature gradients (e.g., hot air rising). - **Forced Convection:** Fluid movement is induced by external means (e.g., pumps, fans). - **Example:** Heating water in a pot, a fan blowing cool air, blood circulation. - **Radiation:** Transfer of heat through electromagnetic waves, without the need for a medium. - **Mechanism:** All objects above absolute zero emit thermal radiation. The energy is carried by photons. - **Example:** Heat from the sun, heat from a glowing heater, heat from a fire. #### Fourier’s Law (for Conduction) Fourier's Law quantifies the rate of heat conduction. $$Q = -kA \frac{dT}{dx}$$ Where: - $Q$ = rate of heat transfer (W or J/s) - $k$ = thermal conductivity of the material (W/m·K) - $A$ = cross-sectional area perpendicular to heat flow (m²) - $\frac{dT}{dx}$ = temperature gradient (K/m) - The negative sign indicates that heat flows in the direction of decreasing temperature. **Thermal Conductivity ($k$):** A material property that indicates its ability to conduct heat. High $k$ means a good conductor (e.g., metals), low $k$ means a good insulator (e.g., air, plastics). #### Heat Transfer by: - **Conduction:** - **Steady-state conduction through a plane wall:** $$Q = \frac{k A (T_1 - T_2)}{L}$$ Where $L$ is the thickness of the wall. - **Conduction through composite walls:** For multiple layers, the concept of thermal resistance is used. $$Q = \frac{T_1 - T_n}{\sum \frac{L_i}{k_i A}}$$ - **Conduction through cylindrical walls:** Used for pipes and tubes. $$Q = \frac{2 \pi k L (T_1 - T_2)}{\ln(r_2/r_1)}$$ - **Convection:** - **Newton's Law of Cooling:** Describes convective heat transfer. $$Q = h A (T_s - T_f)$$ Where: - $h$ = convective heat transfer coefficient (W/m²·K) - $A$ = surface area (m²) - $T_s$ = surface temperature (K) - $T_f$ = fluid temperature (K) - **Convective heat transfer coefficient ($h$):** Depends on fluid properties, flow velocity, geometry, and surface roughness. It is determined experimentally or through empirical correlations. - **Radiation:** - **Stefan-Boltzmann Law:** Describes the total radiant heat energy emitted from a surface. $$Q = \epsilon \sigma A T^4$$ Where: - $\epsilon$ = emissivity of the surface (0 to 1, 1 for a perfect blackbody) - $\sigma$ = Stefan-Boltzmann constant ($5.67 \times 10^{-8}$ W/m²·K⁴) - $A$ = surface area (m²) - $T$ = absolute temperature of the surface (K) - **Net radiation exchange between two surfaces:** $$Q_{net} = \epsilon \sigma A (T_1^4 - T_2^4)$$ For two gray bodies, it involves view factors and emissivities. ### Evaporation #### Objectives of Evaporation Evaporation is the process of concentrating a solution by vaporizing the solvent (usually water) to leave a more concentrated liquid product. - **Concentration:** Increasing the concentration of a desired solute in a solution (e.g., fruit juices, extracts, pharmaceutical syrups). - **Crystallization:** Creating supersaturated solutions from which crystals can be formed. - **Solvent Recovery:** In some cases, the vaporized solvent might be condensed and recovered. - **Waste Volume Reduction:** Reducing the volume of liquid waste for easier disposal. - **Pre-treatment for Drying:** Reducing moisture content before final drying steps, which can be more energy-efficient. - **Improving Product Stability:** Concentrating solutions can sometimes improve stability or reduce microbial growth. #### Applications of Evaporation - **Pharmaceutical Industry:** - **Concentration of extracts:** From herbal raw materials. - **Manufacture of syrups and elixirs:** Achieving desired consistency and drug concentration. - **Preparation of bulk drug intermediates:** Concentrating reaction mixtures. - **Recovery of solvents:** From dilute solutions. - **Food Industry:** Concentrating milk, fruit juices, sugar solutions, tomato paste. - **Chemical Industry:** Concentrating acids, salts, various chemical solutions. - **Environmental Engineering:** Wastewater treatment, concentrating industrial effluents. #### Factors Influencing Evaporation - **Temperature:** Higher temperature of the heating medium (steam) increases the temperature difference, leading to a higher evaporation rate. - **Concentration of Product:** As the solution becomes more concentrated, its boiling point rises (boiling point elevation), and its viscosity increases, both of which reduce the evaporation rate. - **Surface Area:** Larger heat transfer surface area in the evaporator increases the rate of evaporation. - **Temperature Difference ($\Delta T$):** The driving force for heat transfer. A larger difference between the heating medium temperature and the boiling liquid temperature increases the rate. - **Pressure:** Lower operating pressure (vacuum evaporation) reduces the boiling point of the solvent, allowing evaporation at lower temperatures, which is beneficial for heat-sensitive materials. - **Viscosity:** Increased viscosity of the solution reduces heat transfer coefficients and can lead to fouling. - **Fouling:** Deposition of solids on the heat transfer surfaces, which reduces the overall heat transfer coefficient and efficiency. - **Foaming:** Some solutions tend to foam, which can reduce efficiency and lead to product loss. - **Agitation:** Improves heat transfer and prevents local overheating/fouling. #### Difference Between Evaporation and Other Heat Transfer Processes - **Evaporation vs. Drying:** - **Evaporation:** Removes solvent (usually water) from a *solution* to produce a *concentrated liquid* or slurry. The concentrate is the desired product. - **Drying:** Removes solvent (usually water) from a *solid, semi-solid, or liquid* to produce a *dry solid*. The solid is the desired product. - **Evaporation vs. Distillation:** - **Evaporation:** Separates a volatile solvent from a non-volatile solute. The vaporized solvent is usually discarded or recovered without significant separation of components. The objective is to concentrate the liquid. - **Distillation:** Separates two or more *volatile liquids* or a volatile liquid from a non-volatile solute by differences in their boiling points. Both vapor and liquid are typically valuable products, and the vapor is condensed to recover purified liquid. The objective is to separate components. - **Evaporation vs. Boiling:** - **Boiling:** A specific type of evaporation where vaporization occurs throughout the bulk of the liquid, characterized by bubble formation. It occurs at the boiling point. - **Evaporation (general):** Can occur at any temperature where molecules have enough energy to escape the liquid surface, even below the boiling point (e.g., water evaporating from a puddle). Boiling is a rapid form of evaporation. ### Distillation #### Basic Principles of Distillation Distillation is a process used to separate components of a liquid mixture based on differences in their volatilities (i.e., their tendency to vaporize). - **Vapor-Liquid Equilibrium:** When a liquid mixture is heated, the more volatile components vaporize preferentially, leading to a vapor phase enriched in the more volatile component and a liquid phase depleted of it. - **Relative Volatility ($\alpha$):** A measure of the ease of separation of two components. It is the ratio of the vapor pressure of the more volatile component to that of the less volatile component. A higher $\alpha$ indicates easier separation. - **Boiling Point Difference:** Components with significantly different boiling points are easier to separate by distillation. - **Heat and Mass Transfer:** Heat is supplied to vaporize the liquid, and mass transfer occurs as components move between liquid and vapor phases. - **Condensation:** The vapor phase is then cooled and condensed back into a liquid, resulting in a product enriched in the more volatile component (distillate) and a residual liquid depleted of it (bottoms). #### Methodology of Distillation - **Simple Distillation:** Used to separate liquids with significantly different boiling points (difference > 25°C) or to separate a volatile liquid from a non-volatile solute. - **Process:** The liquid mixture is heated, vapor is formed, rises, is condensed, and collected as distillate. - **Equipment:** Distilling flask, condenser, receiver. - **Fractional Distillation:** Used to separate liquids with close boiling points ( ### Drying #### Objectives of Drying Drying is a mass transfer operation that involves the removal of a volatile liquid (usually water) from a solid, semi-solid, or liquid by evaporation, typically using heat. - **Preservation:** Preventing microbial growth and enzymatic reactions, extending shelf life (e.g., food, pharmaceuticals). - **Reduce Weight and Volume:** Lowering transportation costs and storage space requirements. - **Improve Handling and Flow Properties:** Converting sticky or difficult-to-handle materials into free-flowing powders or granules. - **Facilitate Further Processing:** Preparing materials for milling, compression (tablets), or other operations. - **Enhance Product Quality:** Improving appearance, taste, or stability. - **Achieve Desired Moisture Content:** Meeting specifications for final product quality. - **Prevent Corrosion:** Removing moisture from metal parts. #### Applications of Drying - **Pharmaceutical Industry:** - **Drying of granules:** Before tablet compression or capsule filling. - **Drying of active pharmaceutical ingredients (APIs):** After crystallization or precipitation. - **Drying of herbal extracts:** To produce powders. - **Drying of biological products:** Lyophilization (freeze-drying) for vaccines, proteins. - **Food Industry:** Drying fruits, vegetables, grains, milk powder. - **Chemical Industry:** Drying polymers, catalysts, pigments. - **Ceramic Industry:** Drying clay products. - **Textile Industry:** Drying fabrics. #### Mechanism of Drying Process Drying is a complex process involving simultaneous heat and mass transfer. - **Heat Transfer:** Heat is supplied to the wet material to provide the latent heat of vaporization for the moisture. This can be by conduction, convection, or radiation. - **Mass Transfer:** The vaporized moisture is then transferred from the surface of the material into the surrounding drying medium (air or gas). - **Internal Moisture Movement:** Moisture moves from the interior of the solid to the surface. This can occur by: - **Diffusion:** Movement of liquid or vapor due to concentration gradients. - **Capillary Flow:** Movement of liquid through porous structures. - **Pressure Gradients:** Due to vaporization within the material. - **Gravity:** For very wet materials. #### Equilibrium Moisture Content (EMC) - **Definition:** The moisture content of a material when it is in equilibrium with the surrounding air (at a given temperature and relative humidity). At EMC, there is no net exchange of moisture between the material and the air. - **Bound Water:** Moisture that is adsorbed on the surface or held within capillaries by forces stronger than those of pure water. It exerts a lower vapor pressure than pure water. - **Unbound Water:** Moisture that is held in the interstices of the material and exerts the same vapor pressure as pure water at the same temperature. - **Significance:** Drying can only remove unbound and some bound water until the material reaches its EMC. To dry below EMC, more extreme conditions (lower humidity, higher temperature, vacuum) are needed. #### Measurement of Equilibrium Moisture Content - **Desiccator Method:** Placing a sample in a desiccator over saturated salt solutions (which maintain specific relative humidities) at a constant temperature. The change in weight is monitored until equilibrium is reached. - **Dynamic Vapor Sorption (DVS):** A more advanced method where a microbalance continuously measures the weight change of a sample as the surrounding humidity is precisely controlled and varied. - **Isotherms:** Plotting EMC against relative humidity at a constant temperature gives a sorption isotherm, which characterizes how a material interacts with moisture. #### Rate of Drying Curve The rate of drying curve plots the drying rate (mass of water evaporated per unit time per unit surface area) against the moisture content of the material. It typically shows distinct phases: 1. **Constant Rate Period:** - Occurs when the surface of the material remains saturated with moisture, behaving like a free water surface. - The drying rate is constant and depends on external conditions (air temperature, humidity, velocity, surface area). - Heat transfer to the surface provides the latent heat for evaporation. - Moisture movement from the interior to the surface is fast enough to replenish the evaporating surface moisture. - Only unbound water is removed in this phase. 2. **First Falling Rate Period:** - Occurs when the surface is no longer fully saturated. Dry spots begin to appear. - The rate of drying decreases linearly as the dry area expands. - The rate of moisture movement from the interior to the surface becomes the limiting factor. - Both unbound and some bound water are removed. 3. **Second Falling Rate Period:** - Occurs when the surface is completely dry, and moisture must diffuse from the interior through the dry solid to the surface. - The drying rate decreases sharply, often exponentially, as the moisture content approaches the equilibrium moisture content. - The primary mechanism of moisture movement is diffusion. - Primarily bound water is removed in this phase. ### Mixing #### Objectives of Mixing Mixing (or blending) is the process of combining two or more components (solids, liquids, gases) to achieve a uniform distribution throughout the mixture. - **Homogeneity:** Creating a uniform blend of ingredients, ensuring consistent product quality and dosage. - **Physical Change:** Promoting physical changes like dissolution, emulsification, or suspension. - **Heat and Mass Transfer:** Enhancing heat transfer (e.g., in reactors) and mass transfer (e.g., dissolution, extraction). - **Chemical Reaction:** Bringing reactants into intimate contact to facilitate chemical reactions. - **Dispersion:** Dispersing fine particles in a liquid to form suspensions or dispersing one liquid in another to form emulsions. - **Dissolution:** Accelerating the dissolving of solids in liquids. - **Improving Process Efficiency:** Ensuring consistent feed to downstream processes. #### Applications of Mixing - **Pharmaceutical Industry:** - **Powder blending:** Mixing active pharmaceutical ingredients (APIs) with excipients for tablets, capsules, or dry powders. - **Granulation:** Mixing powders with binders during wet granulation. - **Suspensions and Emulsions:** Preparing liquid dosage forms. - **Ointments and Creams:** Blending components to achieve homogeneity. - **Sterile products:** Mixing components aseptically. - **Food Industry:** Mixing ingredients for dough, beverages, sauces. - **Chemical Industry:** Blending reactants, preparing solutions. - **Cosmetics Industry:** Mixing ingredients for lotions, shampoos. #### Factors Affecting Mixing - **Properties of Materials:** - **Particle Size and Shape (for solids):** Large differences can lead to segregation. Irregular shapes can entangle. - **Density (for solids and liquids):** Density differences can cause segregation in solids or stratification in liquids. - **Flowability/Cohesiveness (for solids):** Free-flowing powders mix easily; cohesive powders can clump. - **Viscosity (for liquids):** High viscosity makes mixing more difficult and requires more power. - **Surface Properties (for solids):** Electrostatic charges can cause agglomeration. - **Mixer Design:** - **Type of Mixer:** Ribbon blender, V-blender, planetary mixer, propeller mixer, turbine mixer, etc. - **Impeller/Blade Design:** Affects flow patterns and shear forces. - **Vessel Geometry:** Shape of the mixing tank, presence of baffles. - **Operating Conditions:** - **Mixing Speed/Intensity:** Higher speed generally increases mixing rate, but too high can cause segregation or damage products. - **Mixing Time:** Sufficient time is needed to achieve homogeneity. - **Batch Size:** Affects scale-up and mixer choice. - **Environmental Factors:** Temperature, humidity. #### Difference Between Solid Mixing and Liquid Mixing - **Solid Mixing:** - **Challenge:** Tendency for segregation (unmixing) due to differences in particle size, density, and shape. - **Mechanisms:** Convection (bulk movement), shear (slip planes), diffusion (random particle movement). - **Equipment:** Tumble mixers (V-blender, double cone), fixed shell mixers (ribbon blender, planetary mixer). - **Assessment:** Sampling and assaying for content uniformity. - **Liquid Mixing:** - **Challenge:** Achieving uniform concentration, especially for immiscible liquids or high-viscosity fluids. - **Mechanisms:** Bulk flow (convection), turbulent flow, laminar flow (for high viscosity). - **Equipment:** Agitators (propellers, turbines, paddles), static mixers. - **Assessment:** Visual inspection, concentration measurement, rheological properties. #### Mechanism of: - **Solid Mixing:** - **Convective Mixing (Macro-mixing):** Large groups of particles are moved from one location to another within the mixer. Achieved by tumbling action or blades. - **Shear Mixing:** Layers of particles slide over one another, reducing particle size gradients. Occurs in ribbon blenders or between surfaces. - **Diffusive Mixing (Micro-mixing):** Individual particles move randomly, distributing themselves throughout the mixture. Occurs during tumbling or vibration. - **Segregation:** The opposite of mixing, where particles separate due to differences in size, density, or shape. Can occur during mixing, discharge, or transport. - **Liquid Mixing:** - **Bulk Flow (Convection):** Large-scale movement of liquid throughout the vessel, created by impellers. This distributes components broadly. - **Turbulent Flow:** Random, chaotic movement of fluid elements at a microscopic level. Creates eddies that rapidly disperse components. Most effective for low-viscosity liquids. - **Laminar Flow (Streamline Flow):** For highly viscous liquids, mixing occurs by stretching and folding fluid elements. Requires high shear and long mixing times. Impellers like anchors or helical ribbons are used. - **Semisolid Mixing:** - **Mechanism:** Involves a combination of bulk flow, shearing, and sometimes compression, due to the high viscosity and often non-Newtonian nature of semisolid materials (e.g., ointments, creams, pastes). - **Equipment:** Planetary mixers, sigma blade mixers, triple roll mills, high-shear homogenizers. These mixers are designed to handle high viscosities and provide intense shear to break down agglomerates and ensure uniform dispersion. - **Challenges:** Air entrapment, heat generation, ensuring uniform dispersion of active ingredients and excipients in a highly viscous base. ### Filtration #### Objectives of Filtration Filtration is a mechanical or physical operation which separates solids from fluids (liquids or gases) by interposing a medium through which only the fluid can pass. - **Clarification:** Removing small amounts of solids from a large volume of fluid (e.g., clarifying syrups, parenteral solutions). - **Sterilization:** Removing microorganisms from heat-sensitive liquids or gases using membrane filters. - **Product Recovery:** Collecting the solid particles as the desired product (e.g., active pharmaceutical ingredient crystals). - **Purification:** Removing undesirable solid impurities from a liquid or gas. - **Environmental Protection:** Treating wastewater or air emissions to remove pollutants. - **Particle Size Analysis:** Separating particles into different size fractions. #### Applications of Filtration - **Pharmaceutical Industry:** - **Sterile filtration:** For parenteral solutions, ophthalmic solutions, biological products. - **Clarification of liquids:** Syrups, elixirs, extracts. - **Harvesting crystals:** APIs, excipients. - **Air filtration:** In cleanrooms (HEPA filters). - **Water purification:** For process water. - **Food and Beverage Industry:** Clarifying juices, wine, beer; filtering edible oils. - **Chemical Industry:** Separating catalysts, pigments, chemical precipitates. - **Environmental Engineering:** Water treatment, sewage treatment. - **Automotive Industry:** Oil filters, air filters. #### Theories of Filtration - **Darcy's Law:** Describes the flow of fluid through a porous medium. It states that the flow rate is proportional to the pressure drop and inversely proportional to the resistance of the filter cake and medium. $$ \frac{dV}{dt} = \frac{A \Delta P}{\mu (\alpha C V_c / A + R_m)} $$ Where: - $dV/dt$ = filtration rate - $A$ = filter area - $\Delta P$ = pressure drop across the filter - $\mu$ = fluid viscosity - $\alpha$ = specific cake resistance - $C$ = concentration of solids in the feed - $V_c$ = volume of filtrate - $R_m$ = filter medium resistance - **Assumptions:** Laminar flow, incompressible cake, constant viscosity. - **Kozeny-Carman Equation:** Relates the permeability of a porous medium to the properties of the particles and the void fraction. It helps in understanding the specific cake resistance ($\alpha$). $$ \alpha = \frac{180 (1-\epsilon)^2}{d_p^2 \rho_p \epsilon^3} $$ Where: - $\epsilon$ = porosity of the cake - $d_p$ = particle diameter - $\rho_p$ = density of particles #### Factors Influencing Filtration - **Pressure Drop ($\Delta P$):** The driving force. A higher pressure drop generally increases the filtration rate, but can also compress the filter cake, increasing its resistance. - **Filter Area ($A$):** Larger area provides a higher filtration rate for a given pressure drop. - **Viscosity of Filtrate ($\mu$):** Higher viscosity reduces the filtration rate. Temperature control can reduce viscosity. - **Specific Cake Resistance ($\alpha$):** Property of the filter cake. Influenced by particle size, shape, and compressibility. Finer particles, irregular shapes, and compressible cakes have higher resistance. - **Concentration of Solids in Feed ($C$):** Higher concentration leads to faster cake formation and thus higher cake resistance, potentially reducing the overall filtration rate. - **Filter Medium Resistance ($R_m$):** Resistance offered by the filter cloth or membrane. - **Temperature:** Affects viscosity of the fluid and sometimes the compressibility of the cake. - **Particle Size and Shape:** Finer, more irregular particles form a denser, more resistant cake. - **Compressibility of Cake:** Incompressible cakes (rigid particles) offer constant resistance. Compressible cakes (gelatinous, colloidal) increase resistance with increasing pressure, making high pressure detrimental. #### Filter Aids Filter aids are inert, porous materials added to a suspension to improve filtration rate and clarity by forming a more porous and incompressible filter cake. - **Mechanism:** - **Increased Porosity:** They increase the void volume of the cake, making it less dense and more permeable. - **Reduced Compressibility:** They act as a rigid framework, preventing the cake from becoming too dense under pressure. - **Pre-coating:** A layer of filter aid applied to the filter medium before filtration to prevent fine particles from blinding the medium and to facilitate cake discharge. - **Body-feed:** Filter aid continuously added to the feed suspension during filtration to maintain porosity throughout the cake. - **Characteristics:** Inert, insoluble, low specific gravity, irregular particle shape, porous. - **Examples:** Diatomaceous earth (Kieselguhr), perlite, cellulose, activated carbon (also adsorbent). - **Considerations:** Must not interact with the product, must be easily removable from the product, can add to disposal costs. #### Filter Media The filter medium is the porous material that separates the solid particles from the fluid. - **Requirements:** - **Retain Solids:** Must effectively prevent passage of solid particles. - **Allow Fluid Passage:** Must have sufficient permeability to allow reasonable flow rate. - **Chemical and Physical Stability:** Resistant to chemical attack, temperature, and pressure. - **Mechanical Strength:** Withstand operating pressures and cleaning. - **Regenerability:** Easily cleaned or replaced. - **Cost-effective:** Economical to use. - **Types of Filter Media:** - **Woven Fabrics:** Cotton, wool, synthetic fibers (nylon, polypropylene, polyester). Used in plate-and-frame filters, filter presses. - **Non-woven Fabrics:** Felt, paper pulp. - **Perforated Sheets:** Metal screens, used as support for other media or for coarse filtration. - **Porous Solids:** Sintered glass, ceramics, metal, carbon. Used for fine filtration, high temperature/pressure applications. - **Membranes:** Polymeric membranes (cellulose acetate, polysulfone), ceramic membranes. Used for sterile filtration, ultrafiltration, microfiltration, reverse osmosis. Characterized by pore size. - **Loose Particulate Beds:** Sand filters. ### Centrifugation #### Objectives of Centrifugation Centrifugation is a mechanical process that uses centrifugal force to separate components of a mixture based on differences in their density, particle size, and shape. - **Separation of Immiscible Liquids:** Separating two liquids with different densities (e.g., oil from water). - **Clarification of Liquids:** Removing small amounts of solid particles from a liquid (e.g., clarifying fermentation broths). - **Concentration of Suspensions:** Concentrating solid particles from a dilute suspension (e.g., harvesting cells, concentrating slurries). - **Separation of Solids from Liquids:** Removing solids from large volumes of liquids (e.g., dewatering crystals). - **Fractionation of Biological Materials:** Separating cells, organelles, proteins, DNA by differential centrifugation. #### Principle of Centrifugation - **Sedimentation under Gravity:** In a gravitational field, particles denser than the fluid settle, and lighter particles float. The rate of sedimentation is proportional to the square of the particle diameter and the density difference. - **Centrifugal Force:** In a centrifuge, the gravitational force is replaced by a much stronger centrifugal force. When a mixture is rotated at high speed, particles experience an outward centrifugal force ($F_c$). $$F_c = m r \omega^2$$ Where: - $m$ = mass of the particle - $r$ = radial distance from the axis of rotation - $\omega$ = angular velocity (radians/s) - **Stokes' Law (modified for centrifugation):** The rate of sedimentation in a centrifuge is given by: $$ v = \frac{d_p^2 (\rho_p - \rho_L) \omega^2 r}{18 \mu} $$ Where: - $v$ = sedimentation velocity - $d_p$ = particle diameter - $\rho_p$ = particle density - $\rho_L$ = liquid density - $\omega$ = angular velocity - $r$ = radial distance - $\mu$ = fluid viscosity - **G-force (Relative Centrifugal Force, RCF):** Often expressed as multiples of the acceleration due to gravity ($g$). $$RCF = \frac{r \omega^2}{g}$$ A higher RCF means faster separation. #### Applications of Centrifugation - **Pharmaceutical Industry:** - **Harvesting cells:** From fermentation broths (e.g., vaccines, antibiotics). - **Separating blood components:** Plasma, serum, red blood cells. - **Purification of proteins and nucleic acids:** In biotechnology. - **Dewatering crystals:** After crystallization (e.g., active drug substances). - **Clarification of syrups and solutions:** Removing fine particulates. - **Separation of immiscible phases:** In liquid-liquid extraction. - **Chemical Industry:** Separating polymers, catalysts, pigments. - **Food Industry:** Cream separation from milk, clarifying fruit juices, removing yeast from beer. - **Environmental Science:** Separating sludge from wastewater. - **Clinical Laboratories:** Preparing samples for analysis. ### Materials of Pharmaceutical Plant Construction #### Factors Affecting Selection of Materials for Pharmaceutical Plant Construction The choice of material for pharmaceutical equipment is critical for product quality, safety, and process efficiency. - **Product Compatibility (Chemical Resistance):** - **Corrosion:** Material must resist attack by raw materials, intermediates, solvents, and cleaning agents. Corrosion can lead to product contamination and equipment failure. - **Leaching:** Material components must not leach into the product, which could cause contamination or alter product properties. - **Adsorption/Absorption:** Material should not adsorb or absorb product components, leading to loss of product or cross-contamination. - **Mechanical Properties:** - **Strength:** Must withstand operating pressures, temperatures, and mechanical stresses. - **Hardness/Abrasion Resistance:** For handling abrasive materials (e.g., powders). - **Ductility/Malleability:** Ease of fabrication and repair. - **Thermal Properties:** - **Thermal Conductivity:** Important for heat transfer equipment (e.g., heat exchangers, dryers). - **Thermal Expansion:** Must be considered for large equipment or temperature cycling. - **High Temperature Resistance:** For sterilization, high-temperature reactions. - **Surface Properties:** - **Smoothness/Cleanability:** Non-porous, smooth surfaces are easier to clean and sanitize, preventing microbial growth and cross-contamination (e.g., polished stainless steel). - **Non-stick Properties:** For handling sticky materials. - **Cost:** Initial purchase cost, installation, maintenance, and replacement costs. - **Availability:** Readily available in required forms (sheets, pipes, fittings). - **Regulatory Compliance:** Materials must meet pharmacopoeial standards (e.g., USP Class VI for plastics) and regulatory requirements (e.g., FDA, EMEA). - **Fabricability:** Ease of welding, machining, forming. - **Safety:** Non-toxic, non-flammable. - **Sterilization Compatibility:** Must withstand steam sterilization (autoclaving), dry heat, or chemical sterilization methods without degradation. ### Corrosion #### Theories of Corrosion Corrosion is the deterioration of a material, usually a metal, due to a chemical or electrochemical reaction with its environment. - **Electrochemical Theory (Most Common):** Explains corrosion as an electrochemical process involving an anode, a cathode, an electrolyte, and a metallic path. - **Anode:** Where oxidation occurs (metal dissolves, e.g., Fe → Fe²⁺ + 2e⁻). - **Cathode:** Where reduction occurs (e.g., O₂ + 2H₂O + 4e⁻ → 4OH⁻ in neutral solutions; 2H⁺ + 2e⁻ → H₂ in acidic solutions). - **Electrolyte:** Conductive medium (e.g., water with dissolved salts or acids). - **Metallic Path:** Connects anode and cathode, allowing electron flow. - **Corrosion Cell:** The combination of these four components. - **Direct Chemical Attack (Dry Corrosion):** Reaction of a metal directly with a non-aqueous environment (e.g., oxidation of metals at high temperatures in air, reaction with dry gases like chlorine). No electrolyte involved. #### Types of Corrosion - **Uniform (General) Corrosion:** Occurs evenly over the entire surface of the metal. Predictable and relatively easy to manage. (e.g., rusting of steel in atmosphere). - **Galvanic Corrosion:** Occurs when two dissimilar metals are in electrical contact in an electrolyte. The more anodic metal corrodes preferentially. (e.g., steel bolted to copper in seawater). - **Pitting Corrosion:** Localized corrosion that results in small holes or "pits" in the metal surface. Can be very destructive as it's hard to detect. (e.g., stainless steel in chloride solutions). - **Crevice Corrosion:** Occurs in confined spaces (crevices) where stagnant solution exists, leading to localized depletion of oxygen and pH changes. (e.g., under gaskets, bolts, or deposits). - **Intergranular Corrosion:** Occurs along the grain boundaries of a metal, often due to sensitization (e.g., chromium depletion in stainless steel during welding). - **Stress Corrosion Cracking (SCC):** Cracking of a metal under the combined action of tensile stress and a corrosive environment. (e.g., stainless steel in hot chloride solutions). - **Erosion Corrosion:** Accelerated attack due to the combined action of corrosion and mechanical erosion (e.g., high-velocity fluid flow, abrasive particles). - **Dealloying (Selective Leaching):** Preferential removal of one element from an alloy (e.g., dezincification of brass). - **Microbial Corrosion (Biocorrosion):** Corrosion influenced by the presence and activity of microorganisms. #### Factors Affecting Corrosion - **Nature of the Metal:** - **Electrochemical Potential:** Position in the galvanic series. - **Purity:** Impurities can create local galvanic cells. - **Surface Finish:** Rough surfaces can harbor corrosive agents. - **Passivity:** Ability to form a protective oxide layer (e.g., stainless steel, aluminum). - **Nature of the Environment (Corrosive Medium):** - **pH:** Acidic and alkaline solutions are generally more corrosive. - **Temperature:** Higher temperatures usually accelerate corrosion rates. - **Concentration of Corrosive Agents:** Higher concentration of ions (e.g., chloride) or dissolved oxygen. - **Dissolved Gases:** Oxygen often accelerates corrosion; CO₂ can form carbonic acid. - **Velocity of Fluid:** Can cause erosion-corrosion or remove protective films. - **Metallurgical Factors:** - **Grain Structure:** Intergranular precipitation. - **Residual Stress:** From fabrication processes. - **Design Factors:** Poor drainage, crevices, sharp corners. - **Presence of Microorganisms:** Can alter local chemistry. #### Prevention of Corrosion - **Material Selection:** Choosing corrosion-resistant alloys (e.g., stainless steel, Hastelloy, titanium) suitable for the specific environment. - **Protective Coatings:** - **Metallic Coatings:** Galvanizing (zinc), electroplating (nickel, chromium). - **Non-metallic Coatings:** Paints, varnishes, enamels, plastic linings (e.g., PTFE, glass lining). - **Corrosion Inhibitors:** Chemicals added to the corrosive environment to reduce corrosion rate (e.g., passivators, scavengers). - **Cathodic Protection:** Making the metal to be protected the cathode of an electrochemical cell. - **Sacrificial Anode:** Connecting a more anodic metal (e.g., magnesium, zinc) that corrodes preferentially. - **Impressed Current:** Applying an external DC current to force the metal into a cathodic state. - **Anodic Protection:** For metals that exhibit passivity (e.g., stainless steel), applying an external current to maintain the passive film. - **Design Modifications:** Eliminating crevices, ensuring good drainage, avoiding sharp bends, proper welding techniques. - **Environmental Control:** - **Deaeration:** Removing dissolved oxygen. - **Dehumidification:** Reducing moisture. - **pH Control:** Adjusting pH to a less corrosive range. - **Temperature Control:** Operating at lower temperatures. - **Proper Fabrication and Installation:** Avoiding stress concentrations, using appropriate welding procedures. ### Materials of Construction #### Ferrous Metals Metals primarily composed of iron, often with carbon and other alloying elements. - **Cast Iron:** - **Properties:** High compressive strength, good castability, low cost, good damping capacity. - **Limitations:** Brittle, low tensile strength, poor corrosion resistance (especially to acids). - **Applications:** Machine bases, non-critical parts, some pipes. - **Carbon Steel:** - **Properties:** Strong, ductile, weldable, relatively inexpensive. - **Limitations:** Poor corrosion resistance (rusts easily), susceptible to high-temperature degradation. - **Applications:** Structural components, storage tanks, non-corrosive fluid lines. - **Stainless Steel:** (Most widely used in pharma) - **Properties:** Excellent corrosion resistance (due to passive chromium oxide layer), good strength, hygienic, easy to clean, good weldability. - **Types:** - **Austenitic (e.g., 304, 316, 316L):** Non-magnetic, excellent corrosion resistance, good ductility. 316L is preferred in pharma for its lower carbon content, reducing intergranular corrosion after welding. - **Ferritic:** Magnetic, lower corrosion resistance than austenitic. - **Martensitic:** Hard, can be heat-treated. - **Limitations:** Susceptible to chloride-induced pitting and stress corrosion cracking (though 316L is better), higher cost than carbon steel. - **Applications:** Reaction vessels, storage tanks, pipes, heat exchangers, valves, pumps, cleanroom surfaces. #### Non-Ferrous Metals Metals that do not contain iron as their principal component. - **Aluminum and its Alloys:** - **Properties:** Lightweight, good thermal and electrical conductivity, good corrosion resistance (due to passive oxide layer), non-toxic. - **Limitations:** Lower strength than steel, susceptible to attack by strong acids/alkalis. - **Applications:** Storage tanks for non-corrosive liquids, heat exchanger fins, structural components where weight is critical. - **Copper and its Alloys (Brass, Bronze):** - **Properties:** Excellent thermal and electrical conductivity, good ductility, corrosion resistant in certain environments. - **Limitations:** Susceptible to corrosion by strong oxidizing acids, ammonia, and some sulfur compounds. Can contaminate products. - **Applications:** Heat exchanger tubes, heating coils, some piping (less common in pharma due to contamination risk). - **Nickel and its Alloys (e.g., Hastelloy, Inconel, Monel):** - **Properties:** Excellent corrosion resistance (especially to aggressive acids and alkalis), high strength at elevated temperatures. - **Limitations:** Very expensive. - **Applications:** Highly corrosive environments, high-temperature reactors, specialized equipment where stainless steel is insufficient. - **Titanium and its Alloys:** - **Properties:** Excellent corrosion resistance (forms a very stable passive oxide layer), high strength-to-weight ratio. - **Limitations:** Very expensive, difficult to fabricate. - **Applications:** Highly corrosive environments, surgical implants, heat exchangers for aggressive media. #### Inorganic Non-Metals Materials like glass, ceramics, and graphite. - **Glass (e.g., Borosilicate Glass):** - **Properties:** Excellent chemical resistance (except to strong alkalis and hydrofluoric acid), transparent, non-porous, smooth surface, easy to clean, non-contaminating. - **Limitations:** Brittle, poor thermal shock resistance (though borosilicate is better), low mechanical strength. - **Applications:** Laboratory glassware, sight glasses, piping for corrosive non-abrasive fluids, reaction vessels (glass-lined). - **Ceramics (e.g., Porcelain, Alumina):** - **Properties:** Excellent chemical resistance (especially to acids), high hardness, high temperature resistance, abrasion resistance. - **Limitations:** Brittle, poor thermal shock resistance, difficult to fabricate. - **Applications:** Pump components, valves, linings for abrasive/corrosive applications, filtration media. - **Graphite (Carbon):** - **Properties:** Excellent chemical resistance to most acids and alkalis (except strong oxidizers), good thermal conductivity, good high-temperature strength. - **Limitations:** Brittle, porous (requires impregnation), low mechanical strength. - **Applications:** Heat exchangers for corrosive fluids, rupture discs, pump seals. #### Organic Non-Metals (Plastics/Polymers) Synthetic materials used for various applications. - **Properties (General):** Lightweight, corrosion resistant, good electrical insulators, easy to fabricate. - **Limitations (General):** Lower temperature limits, lower mechanical strength than metals, susceptible to solvent attack, some can leach plasticizers. - **Examples:** - **Polyethylene (PE), Polypropylene (PP):** Good chemical resistance, low cost. Used for tanks, pipes for less aggressive fluids, packaging. - **Polyvinyl Chloride (PVC):** Good chemical resistance, rigid. Used for pipes, tanks, ductwork. - **Polytetrafluoroethylene (PTFE, Teflon):** Excellent chemical resistance (almost universal), low friction, non-stick, high temperature resistance. - **Applications:** Gaskets, seals, linings for pipes and vessels, non-stick coatings, medical implants. - **Polycarbonate:** Transparent, high impact strength. Used for sight glasses, safety shields. - **Rubber (Natural and Synthetic):** Used for gaskets, seals, linings, flexible hoses. - **Fiber Reinforced Plastics (FRP):** Strong, corrosion resistant. Used for large tanks, ducts. - **Considerations:** Many plastics are permeable to gases and vapors, can leach additives, and have lower resistance to solvents and high temperatures compared to metals or glass. Must meet biocompatibility standards for direct product contact. ### Material Handling #### Basics of Material Handling Systems Material handling refers to the movement, storage, protection, and control of materials throughout the manufacturing, warehousing, distribution, and disposal processes. Its goal is to minimize costs, improve efficiency, and ensure product quality and safety. **Key Principles of Material Handling (e.g., from the Material Handling Industry of America):** 1. **Planning Principle:** All material handling activities should be planned. 2. **Standardization Principle:** Standardize equipment and methods. 3. **Work Principle:** Material handling work should be minimized. 4. **Ergonomic Principle:** Consider human capabilities and limitations. 5. **Unit Load Principle:** Handle materials in unit loads (e.g., pallets) rather than individual items. 6. **Space Utilization Principle:** Utilize cubic space effectively. 7. **System Principle:** Integrate handling and storage activities into a coordinated system. 8. **Automation Principle:** Automate handling operations where feasible. 9. **Environmental Principle:** Consider environmental impact. 10. **Life Cycle Cost Principle:** Consider total cost of ownership. **Types of Material Handling Equipment:** - **Transport Equipment:** Used to move materials from one point to another. - **Conveyors:** Belt, roller, chain, screw, pneumatic, vibratory. Used for continuous or semi-continuous movement. - **Cranes and Hoists:** Overhead cranes, jib cranes. For lifting and lowering heavy loads. - **Industrial Trucks:** Forklifts, pallet jacks, automated guided vehicles (AGVs). For intermittent movement of unit loads. - **Pumps:** For liquids. - **Pneumatic Conveyors:** For powders and granules using air pressure. - **Gravity Chutes:** For downward movement of solids. - **Positioning Equipment:** Used to handle materials at a single workstation. - **Work positioners:** Lift tables, manipulators, robots. - **Unit Load Formation Equipment:** Used to build and maintain unit loads. - **Pallets, Skids:** For transport by forklifts. - **Containers:** Bins, totes, drums. - **Storage Equipment:** Used for holding materials. - **Racks:** Pallet racks, cantilever racks. - **Shelves:** For smaller items. - **Automated Storage and Retrieval Systems (AS/RS):** Computer-controlled systems for high-density storage. - **Identification and Control Equipment:** For tracking and managing materials. - **Bar codes, RFID:** For automatic identification. - **Warehouse Management Systems (WMS):** Software for inventory control. **Considerations for Pharmaceutical Material Handling:** - **Hygiene and Cleanliness:** Equipment must be easily cleanable, non-shedding, and non-contaminating. Stainless steel is common. - **Cross-Contamination Prevention:** Dedicated equipment or thorough cleaning validation. - **Product Integrity:** Gentle handling to prevent breakage, degradation, or segregation. - **Dust Control:** Enclosed systems, dust collection. - **Containment:** For hazardous or potent compounds. - **GMP Compliance:** All systems must meet Good Manufacturing Practices. - **Traceability:** Ability to track materials throughout the process. - **Automation:** Reduces human intervention, minimizing contamination and errors. #### Explain Each Topic in Detail Exam Ready for 10 Marks University Exam To expand each topic to a "10-mark university exam" level, you would need to: 1. **Elaborate on definitions and principles:** Provide more nuanced explanations. 2. **Include relevant equations and derivations:** Show the mathematical basis where appropriate (e.g., detailed derivations for Darcy's Law, Stokes' Law, Bernoulli's equation). 3. **Discuss specific equipment types in detail:** For example, under "Flow of Fluids," describe different types of pumps and their operating principles; under "Size Reduction," detail the working of a hammer mill, ball mill, fluid energy mill. 4. **Provide more examples and case studies:** Illustrate applications with practical scenarios. 5. **Discuss advantages and disadvantages:** For each method, material, or equipment type. 6. **Include diagrams or schematics:** (If allowed in the exam context) to illustrate equipment or processes. 7. **Discuss operational parameters and their optimization:** For example, how to optimize drying time, mixing efficiency, or filtration rate. 8. **Address troubleshooting and common problems:** What goes wrong and how to fix it (e.g., blinding in filtration, segregation in mixing). 9. **Discuss regulatory aspects:** For pharmaceutical topics, mention GMP, validation, material certifications. 10. **Compare and contrast:** Clearly differentiate between similar concepts (e.g., different types of heat exchangers, different types of centrifuges). **Example of how to expand a single sub-topic (e.g., "Hammer Mill" under Size Reduction):** **Hammer Mill (Detailed for a 10-mark question):** **Principle:** Operates on the principle of impact. Material is fed into a grinding chamber where rapidly rotating hammers (fixed or swing type) strike the material, causing it to shatter against the mill casing or breaker plates. A screen at the bottom of the chamber retains particles until they are small enough to pass through, thus controlling the final particle size. **Construction:** - **Feed Hopper:** For introducing material. - **Grinding Chamber:** Houses the rotor and hammers. - **Rotor:** A central shaft with multiple hammers attached. - **Hammers:** Can be fixed (rigidly attached) or swing (pivot on pins). Swing hammers are preferred as they retract if an ungrindable object enters, protecting the mill. - **Breaker Plates/Liner Plates:** Stationary plates within the chamber that assist in impact. - **Screen/Sieve:** Installed at the discharge, determines the maximum particle size of the product. Screens are interchangeable to achieve different fineness. - **Discharge Chute:** For collecting the milled product. - **Motor:** Provides power for rotation, typically at high speeds (2000-7000 rpm). **Working:** 1. Material is fed into the grinding chamber via the hopper. 2. The rapidly rotating hammers impact the feed material, breaking it into smaller pieces. 3. These pieces are then subjected to further impacts with other particles, the mill casing, and the hammers. 4. The material continues to be impacted until it is reduced to a size that can pass through the perforations of the screen. 5. Finer particles are discharged, while coarser particles are retained for further size reduction. **Factors Affecting Performance:** - **Rotor Speed:** Higher speed increases impact force and fineness. - **Hammer Type and Number:** Affects impact efficiency. - **Screen Size:** Directly controls the maximum particle size. - **Feed Rate:** Optimal feed rate prevents overloading or underloading. - **Material Properties:** Hardness, friability, moisture content. - **Configuration (e.g., top feed vs. side feed).** **Advantages:** - Versatile: Handles a wide range of materials (fibrous, crystalline, friable). - High capacity. - Simple construction and operation. - Easy to clean and maintain. - Can produce a relatively narrow particle size distribution with appropriate screens. **Disadvantages:** - Generates significant heat, unsuitable for heat-sensitive materials unless cooling is provided. - Can be noisy and dusty. - May not achieve very fine particle sizes compared to other mills (e.g., fluid energy mill). - Wear and tear on hammers and screens, especially with abrasive materials. - Potential for segregation if feed is not uniform. **Applications:** - Size reduction of raw materials (e.g., crude drugs, excipients). - Granulation (milling of dry granules). - Recycling of tablets or capsules. - Preparation of powders for blending. By applying this level of detail to each sub-topic, you can generate comprehensive, exam-ready answers.