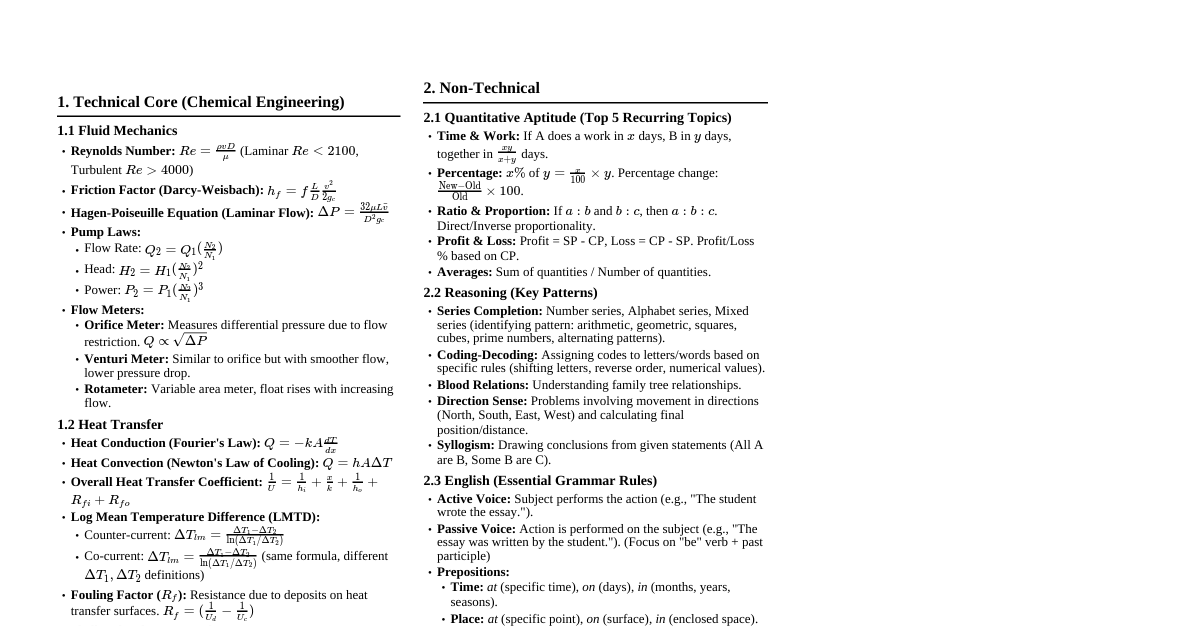

A. Key Concepts a. Reynolds Number ($Re$) Definition: Dimensionless quantity predicting flow patterns in fluid mechanics. Ratio of inertial forces to viscous forces. Formula: $Re = \frac{\rho v L}{\mu}$ $\rho$: fluid density $v$: flow speed $L$: characteristic linear dimension (e.g., pipe diameter) $\mu$: dynamic viscosity Flow Regimes: $Re $2100 $Re > 4000$: Turbulent flow b. Impact as a Mechanism of Size Reduction Principle: Material breakage due to high-speed collision with a hard surface or other particles. Application: Used in hammer mills, impact mills, and cage mills for brittle or friable materials. Mechanism: Kinetic energy transferred upon impact causes stress exceeding material's fracture strength. c. Elutriation Definition: Process of separating particles based on their settling velocity in an upward-flowing fluid. Mechanism: Lighter/smaller particles are carried upwards by the fluid, while heavier/larger particles settle down. Application: Classification of powders, removal of fines, ore dressing. d. Fourier’s Law of Heat Conduction Statement: Rate of heat transfer through a material is proportional to the negative gradient in the temperature and to the area, at right angles to that gradient, through which the heat flows. Formula: $q = -k A \frac{dT}{dx}$ $q$: heat transfer rate $k$: thermal conductivity $A$: area normal to heat flow $\frac{dT}{dx}$: temperature gradient e. Film Evaporators Definition: Evaporators where the liquid forms a thin film on the heat transfer surface, promoting efficient heat transfer and evaporation. Types: Rising film, falling film, wiped film evaporators. Advantages: High heat transfer coefficients, short residence time, suitable for heat-sensitive materials. f. Radial Flow Definition: Fluid flow that moves outwards or inwards from a central point, typically encountered in impellers, centrifuges, or filtration. Example: In a centrifugal pump, fluid enters axially and is discharged radially. In filtration, filtrate often moves radially through the filter medium. g. Fluidization Definition: Process where a bed of solid particles is transformed into a fluid-like state by passing a gas or liquid upwards through it. Mechanism: As fluid velocity increases, drag force on particles balances their weight, suspending them. Applications: Fluidized bed reactors, dryers, granulators. h. Centrifugal Effect Definition: The outward force experienced by an object moving in a circular path, relative to the center of rotation. Principle: Used for separation of components with different densities (e.g., solid-liquid, liquid-liquid) in centrifuges. Heavier components move further from the center. Force: $F_c = m r \omega^2$ ($m$: mass, $r$: radius, $\omega$: angular velocity). i. Volatility Definition: A measure of a substance's tendency to vaporize. Highly volatile substances evaporate readily at room temperature. Factors: Vapor pressure, boiling point, intermolecular forces. Application: Key in distillation, evaporation, and drying processes for separating components based on their boiling points. j. Filter Aids Definition: Inert, porous materials added to a suspension or pre-coated onto a filter medium to improve filtration efficiency. Mechanism: Prevent filter medium blinding, increase cake porosity, and trap fine particles. Examples: Diatomaceous earth, perlite, cellulose. B. Equipment & Processes 2. Construction and Working of Basket Centrifuge Purpose: Separation of solids from liquids, especially for fine particles or when a clear filtrate is required. Components: Outer casing, rotating basket (perforated or non-perforated), drive motor, feed inlet, liquid outlet, solids discharge. Perforated Basket Centrifuge Construction: Basket with perforations lined with a filter cloth or screen. Working: Suspension fed into the rotating basket. Centrifugal force pushes liquid through the filter cloth and perforations, while solids are retained on the cloth. Liquid (filtrate) collected in the outer casing and discharged. Solids (cake) scraped or discharged manually/automatically when the basket rotation stops or slows. Application: Dewatering slurries, separating crystalline products. Non-Perforated Basket Centrifuge (Sedimentation Centrifuge) Construction: Solid-walled basket without perforations. Working: Suspension fed into the rotating basket. Centrifugal force causes denser solid particles to settle against the basket wall, forming a cake. Lighter liquid forms an inner layer and overflows a weir or is decanted. Solids are removed manually after stopping or slowing the centrifuge. Application: Clarification of liquids with low solids content, separation of immiscible liquids. 3. Theory of Corrosion & Types of Corrosion Theory of Corrosion (Electrochemical): Corrosion is an electrochemical process involving an anode (metal oxidation), a cathode (reduction reaction), an electrolyte (conductive medium), and an electrical connection between anode and cathode. Anodic Reaction: $M \rightarrow M^{n+} + ne^-$ (Metal atoms lose electrons and go into solution as ions). Cathodic Reaction: Typically oxygen reduction ($O_2 + 2H_2O + 4e^- \rightarrow 4OH^-$) or hydrogen evolution ($2H^+ + 2e^- \rightarrow H_2$). Electrons flow from anode to cathode, completing the circuit. Types of Corrosion Uniform Corrosion: Occurs evenly over the entire surface of the metal. Most common and predictable. Galvanic Corrosion: Occurs when two dissimilar metals are in electrical contact in an electrolyte. The more active metal corrodes preferentially. Pitting Corrosion: Localized attack forming small holes or pits. Dangerous because it's hard to detect and can lead to sudden failure. Crevice Corrosion: Localized corrosion occurring in confined spaces (crevices) where stagnant solution exists, leading to oxygen depletion and pH changes. Intergranular Corrosion: Localized attack along the grain boundaries of a metal, often due to segregation of impurities or depletion of alloying elements. Stress Corrosion Cracking (SCC): Cracking caused by the combined action of a tensile stress and a corrosive environment. Erosion Corrosion: Accelerated attack due to the combined action of fluid flow (erosion) and corrosion. 4. Rising Film and Falling Film Evaporators Rising Film Evaporator (Long Tube Vertical Evaporator) Construction: Consists of long vertical tubes (e.g., 5-10 m) inside a steam jacket. A vapor-liquid separator is at the top. Working: Liquid feed enters the bottom of the tubes. Steam in the jacket heats the tubes, causing the liquid to boil. Vapor bubbles form, and their expansion creates a "pumping" action, forcing the liquid and vapor upwards as a film along the tube walls (hence "rising film"). High velocity of vapor-liquid mixture leads to good heat transfer. The mixture enters a separator where vapor is separated from the concentrated liquid. Advantages: High heat transfer, suitable for viscous liquids, relatively inexpensive. Disadvantages: Not suitable for highly heat-sensitive or fouling liquids, requires significant height. Falling Film Evaporator Construction: Similar to rising film but feed enters at the top and flows downwards as a thin film inside the tubes. Working: Liquid feed is evenly distributed to flow as a thin, continuous film down the inside surfaces of long vertical tubes. Steam in the jacket heats the tubes, causing evaporation from the falling film. Vapor and concentrated liquid flow downwards, often co-currently. The mixture is collected at the bottom and separated. Advantages: Very short residence time, excellent for heat-sensitive materials, good for high viscosity fluids (after some concentration), high heat transfer coefficients. Disadvantages: Requires good liquid distribution, susceptible to fouling if not properly cleaned. C. Further Topics 5. Factors Affecting Evaporation (Duplicate of 13) Temperature Difference ($\Delta T$): Larger $\Delta T$ between heating medium and boiling liquid increases evaporation rate. Heat Transfer Area ($A$): Larger surface area for heat exchange increases evaporation. Overall Heat Transfer Coefficient ($U$): Affected by material properties, film thickness, fouling, velocity. Higher $U$ means better evaporation. Concentration of Liquid: As concentration increases, boiling point elevation occurs, reducing $\Delta T$ and evaporation rate. Viscosity also increases. Pressure: Lower operating pressure (vacuum) reduces the boiling point of the liquid, increasing $\Delta T$ and evaporation rate. Fouling: Deposition of solids on heat transfer surfaces reduces $U$ and insulation, decreasing evaporation efficiency. Properties of Liquid: Viscosity, density, specific heat, thermal conductivity, and latent heat of vaporization all influence evaporation. 6. Construction and Working of Rotary Drum Filters Purpose: Continuous filtration of slurries, separating solids from liquids. Construction: A large cylindrical drum, typically horizontally mounted, partially submerged in a trough containing the slurry. The drum surface is perforated and covered with a filter medium (cloth or screen). Internal compartments are connected to a rotary valve. Scraper blade for cake removal. Wash sprays, cake drying sections, and sometimes vacuum connections. Working (Continuous Operation): Filtration: As the drum rotates through the slurry, vacuum applied to internal compartments draws liquid through the filter medium, leaving a cake of solids on the drum surface. Washing: As the drum rotates out of the slurry, wash sprays can be applied to displace mother liquor from the cake. Drying: Air is drawn through the cake to partially dry it. Discharge: A scraper blade removes the dried cake from the drum surface, which falls into a conveyor or hopper. The rotary valve continuously switches vacuum/air to different sections of the drum as it rotates. Advantages: Continuous operation, handles large volumes, good for compressible cakes. Disadvantages: High capital cost, not suitable for very fine or sticky solids. 7. Principle and Construction of Orifice Meter Principle: Based on Bernoulli's principle and the principle of continuity. When a fluid flows through a constriction (orifice), its velocity increases and its static pressure decreases. The pressure differential across the orifice is proportional to the square of the flow rate. Construction: Orifice Plate: A thin plate with a precisely machined concentric hole (orifice) in the center. Flanges: The orifice plate is clamped between two flanges in the pipeline. Pressure Taps: Two pressure taps are located upstream and downstream of the orifice plate to measure the pressure differential. Manometer/Differential Pressure Transmitter: Connected to the pressure taps to measure the pressure drop. Working: Fluid flows through the pipe and encounters the orifice plate. The fluid accelerates through the smaller opening, causing a drop in static pressure. The pressure difference ($\Delta P$) is measured. The flow rate ($Q$) can be calculated using the formula: $Q = C_d A_o \sqrt{\frac{2 \Delta P}{\rho (1 - \beta^4)}}$, where $C_d$ is the discharge coefficient, $A_o$ is the orifice area, $\rho$ is fluid density, and $\beta$ is the ratio of orifice diameter to pipe diameter. Advantages: Simple construction, low cost, easy to install/remove. Disadvantages: High permanent pressure loss, susceptible to erosion, limited turndown ratio. 8. Heat Interchangers (Heat Exchangers) Definition: Devices that transfer heat between two or more fluids at different temperatures, typically without direct contact between them. Purpose: Heating or cooling process streams, recovering waste heat, condensation, reboiling. Types: Shell and Tube Heat Exchangers: Most common type. One fluid flows through tubes, the other flows around the tubes (in the shell). Plate Heat Exchangers: Consist of a series of thin, corrugated plates pressed together, creating channels for fluids. High efficiency, compact. Double Pipe Heat Exchangers: One pipe inside another. Simple, used for small flow rates. Fin-Tube Heat Exchangers: Fins are attached to tubes to increase surface area, often used with gases. Regenerative Heat Exchangers: Heat is transferred from one fluid to a solid matrix, then from the matrix to another fluid (e.g., rotary regenerators). Flow Arrangements: Co-current, counter-current, cross-flow. Counter-current is most efficient. 9. Construction and Working of Hammer Mill Purpose: Size reduction (crushing and grinding) of brittle and fibrous materials. Construction: Housing: A rigid casing enclosing the grinding chamber. Rotor: A central shaft with multiple hammers (pivotally or rigidly mounted). Hammers: Impacting elements that swing freely or are fixed, designed to strike the material. Screens/Grates: Perforated screens or grates at the bottom of the mill to control product particle size. Feed Hopper: For introducing material. Discharge Chute: For removing ground product. Working: Material is fed into the grinding chamber through the hopper. The rapidly rotating rotor causes the hammers to swing outwards due to centrifugal force. Material is struck by the hammers at high speed (impact mechanism), shattering it against the housing, other particles, and the screen. Particles continue to be impacted until they are small enough to pass through the screen openings. The ground product is then discharged. Advantages: Versatile, high capacity, simple construction, produces fine powders. Disadvantages: Generates heat, dusty operation, not suitable for sticky or abrasive materials. 10. Conveyors Definition: Mechanical devices used for moving materials, goods, or products from one location to another within a facility or process. Purpose: Automation of material handling, reducing manual labor, improving efficiency and safety. Types: Belt Conveyors: Continuous loop of flexible belt running over pulleys. Used for bulk solids (ore, grain) and packaged goods. Screw Conveyors (Augers): Rotating helical screw within a stationary trough. Used for bulk solids, especially powders and granular materials. Can elevate material. Roller Conveyors: Series of rollers mounted on a frame. Used for flat-bottomed items (boxes, pallets). Can be gravity-driven or powered. Chain Conveyors: Chains with attachments (flights, slats) to carry material. Used for heavy or irregularly shaped items, or in harsh environments. Bucket Elevators: Enclosed casing with continuous buckets attached to a belt or chain. Used for vertical transport of bulk solids. Pneumatic Conveyors: Transport materials (powders, granules) suspended in an air stream through pipelines. Can be dilute phase or dense phase. Selection Factors: Material properties (abrasiveness, size, flowability), capacity, distance, elevation change, environmental conditions, cost. 11. Principle of Flash Distillation Definition: A single-stage distillation process where a liquid mixture is partially vaporized by a sudden reduction in pressure (flashing) after being heated. Principle: The liquid feed mixture is heated to a temperature and pressure such that when its pressure is suddenly reduced, a portion of the liquid instantly vaporizes (flashes). This rapid vaporization occurs when the heated liquid enters a flash drum (or separator) at a lower pressure than its bubble point pressure. The vapor and liquid phases separate in the flash drum. The vapor phase is richer in the more volatile components, and the liquid phase is richer in the less volatile components. The system aims to achieve equilibrium between the liquid and vapor phases in the flash drum. Application: Used for crude oil distillation (initial separation), solvent recovery, and as a component in multi-stage distillation systems. Key Equation: Relies on Raoult's Law and Dalton's Law for vapor-liquid equilibrium calculations. 12. Silverson Mixers Definition: High-shear mixers designed for rapid and efficient mixing, emulsifying, homogenizing, disintegrating, and dissolving. Construction: Typically consist of a high-speed rotor (impeller blade) operating within a stationary stator head. Working Principle: Material is drawn into the center of the stator/rotor head. Centrifugal force drives the material towards the periphery, where it is subjected to intense mechanical and hydraulic shear in the gap between the rotor and stator. This high-shear action rapidly disintegrates solids, creates fine emulsions, and produces homogeneous mixtures. Material is expelled from the stator at high velocity into the bulk of the mixture, creating a circulatory mixing pattern. Types: Batch mixers, in-line mixers, bottom-entry mixers. Applications: Food, pharmaceutical, cosmetic, chemical industries for tasks like creating emulsions, suspensions, dissolving powders, and reducing particle size. 13. Various Factors Affecting Evaporation (Duplicate of 5) Temperature Difference ($\Delta T$): The driving force for heat transfer; a larger difference between the heating medium and the boiling liquid increases the rate of evaporation. Heat Transfer Area ($A$): The total surface area available for heat exchange directly impacts the amount of heat transferred and thus the evaporation rate. Overall Heat Transfer Coefficient ($U$): A measure of the efficiency of heat transfer across the evaporator's heating surface. It's affected by fluid properties, flow velocity, and fouling. Concentration of Liquid: As the liquid concentrates, its boiling point typically increases (boiling point elevation), which reduces the effective $\Delta T$ and lowers the evaporation rate. Viscosity also increases, hindering circulation. Pressure: Operating an evaporator under vacuum (reduced pressure) lowers the boiling point of the liquid, increasing the effective temperature difference and improving evaporation. Fouling: The accumulation of deposits (scale, precipitates) on the heat transfer surfaces reduces the overall heat transfer coefficient, acting as an insulating layer and decreasing efficiency. Physical Properties of the Liquid: Viscosity: Higher viscosity can impede liquid flow and film formation, reducing heat transfer. Density: Affects natural circulation and heat transfer. Specific Heat: Energy required to raise the liquid's temperature to boiling point. Thermal Conductivity: How well the liquid conducts heat. Latent Heat of Vaporization: Energy required to convert liquid to vapor; higher latent heat requires more energy input for evaporation. Liquid Head: In some evaporators, the static head of the liquid can increase the boiling point at the bottom of the tubes, reducing the effective temperature difference. Flow Rate and Distribution: Proper liquid distribution and sufficient flow rate are crucial for maintaining thin films and preventing dry spots in film evaporators.