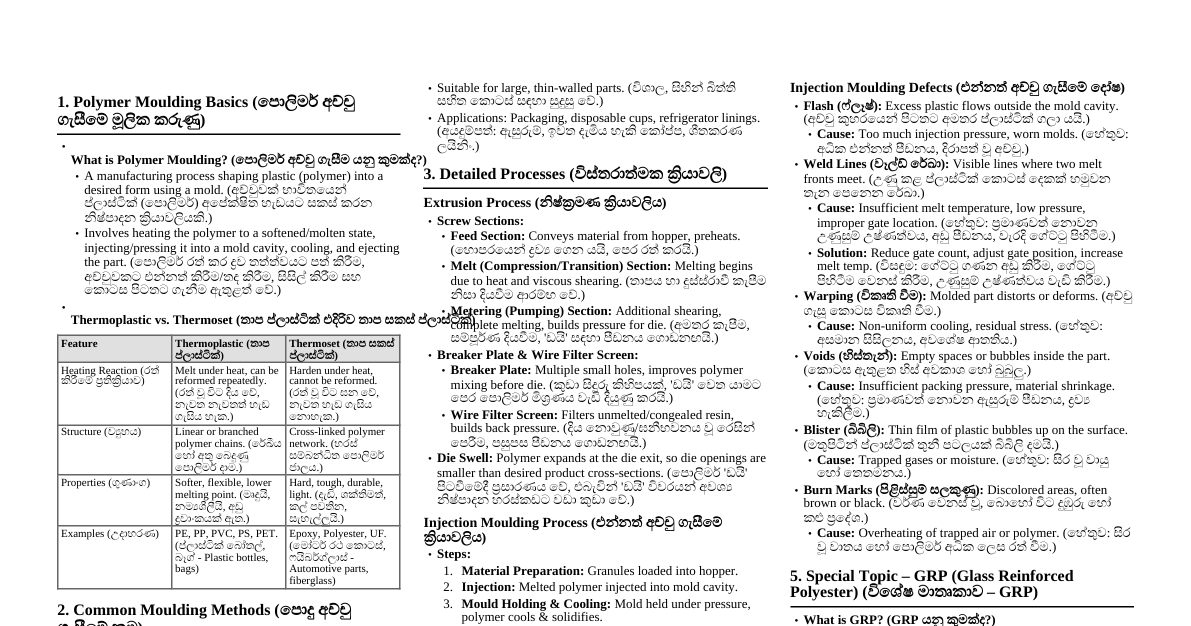

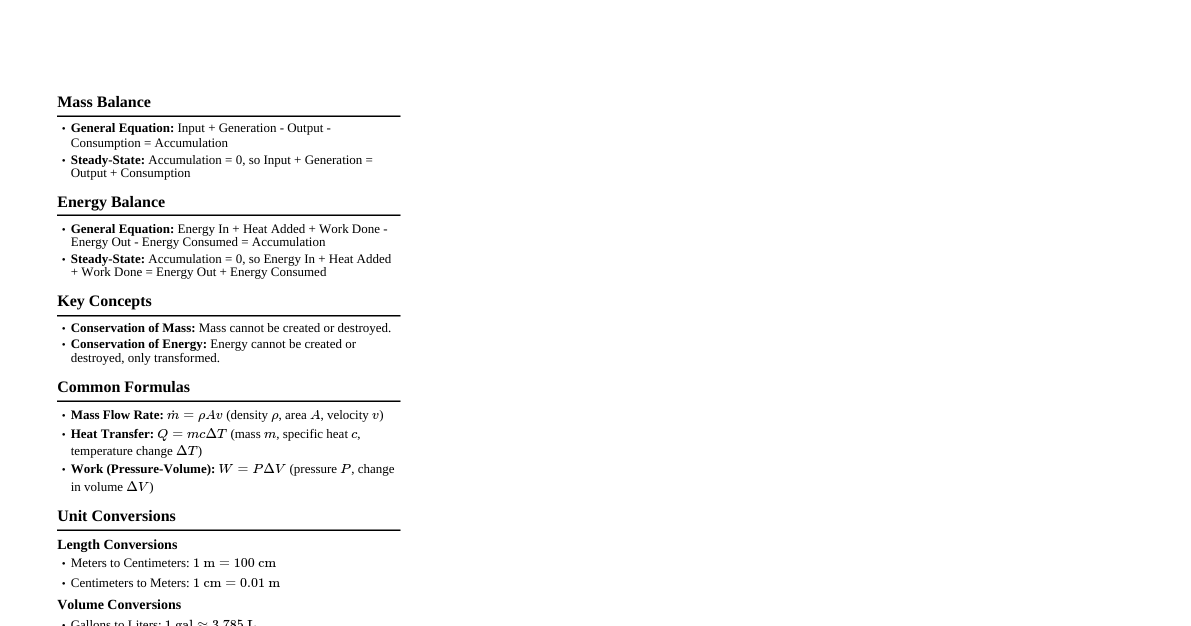

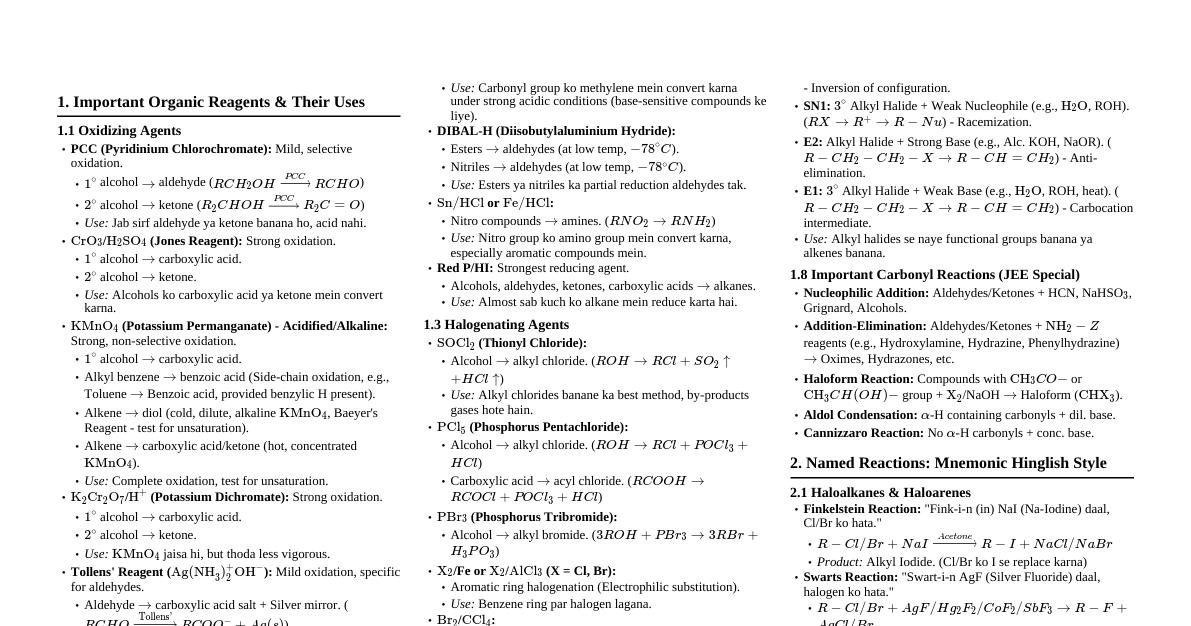

Polymer Moulding (Plastic Moulding) Monomer: A molecule that can be bonded to other identical molecules to form a polymer. Polymer: A large molecule, or macromolecule, composed of many repeated subunits. Repeating unit: The smallest unit of a polymer chain. Polymerization: The process of reacting monomer molecules together in a chemical reaction to form polymer chains. Thermoplastic vs. Thermoset Thermoplastic: Melts under heat, can reform again and again. Examples: Polyethylene, Polypropylene, PVC, Polystyrene, PTFE. Applications: Packaging, electrical insulation, bottles, carpet fibers, automotive bumpers, credit cards, disposable spoons, non-stick coatings. Thermoset: Hardens under heat, cannot reform again and again. Properties: More durable, hard, tough, light. Examples: Elastomers (have rubber-like properties). Applications: Automobile parts, construction materials, boat hulls, furniture, electrical circuits, medical masks, gloves, insulation. What is Polymer Moulding? A manufacturing process where a polymer, typically in a softened or molten state, is shaped into a desired form using a mold. The polymer material is injected or pressed into a mold cavity, cools, solidifies, and is then ejected. Common Methods of Processing Plastics Extrusion Injection Moulding Blow Moulding Rotational Moulding Thermoforming Compression Moulding Transfer Moulding 1. Extrusion Process Description Raw materials (thermoplastic pellets, granules, or powder) are fed into a hopper and then into the barrel of a screw extruder. A helical screw blends and conveys the material down the barrel towards the die. Barrel heaters and internal friction from the screw heat and liquefy the pellets. Screw Sections Feed section: Conveys material from hopper into the central region of the barrel. Melt section (compression or transition section): Heat from viscous shearing and external heaters begins melting. Metering or pumping section: Additional shearing and melting occur, building pressure at the die. Breaker Plate and Wire Filter Screen Breaker plate: Has small holes to improve polymer mixing before entering the die. Wire filter screen: Filters out unmelted/congealed resin and helps build back pressure. Extrusion Characteristics Extruder and die characteristics: Screw rotational speed, polymer viscosity, barrel wall temperatures, die design, cooling rate, drawing speed. These characteristics ensure product integrity and uniform dimensional accuracy. Extrusion Die Polymer swells at the exit of the die, so openings are smaller than the extruded cross-sections. After cooling, the extruded product can be drawn by a puller and coiled or cut. Defects are similar to those in metal extrusion. *Polymer swelling: Volume changes due to solvent molecules entering the polymer matrix. 2. Injection Moulding Process Description Pellets or granules are fed from a hopper into a heated cylinder. Melt is forced into the mold by a hydraulic plunger or rotating screw system. Injection moulding process steps: Material preparation $\rightarrow$ Feeding into hopper $\rightarrow$ Injection $\rightarrow$ Mould holding and cooling $\rightarrow$ Ejection. Working Process Material granules melt in the barrel (surrounded by heaters). Rotating and reciprocating screw builds up polymer in front of the sprue bushing, pushing the screw backward. Rotation stops when enough polymer has built up. Melted material is injected into the mold cavity, and the mold is held under pressure until the material cools and hardens. Once hardened, the mold opens, and the component is ejected by a runner plate. Thermoplastics: Molds kept cool ($\approx 90^\circ C$). Thermoset parts: Molded in heated molds ($\approx 200^\circ C$) for polymerization and cross-linking. Sprue Bushing Connects the machine's nozzle to the mold, allowing molten plastic to enter the mold cavity. Cycle Time Consists of Injection Time (Packing Time, Discharge Time, Sealed Cooling) and Cooling Time (Mold reset time). Mould Tool used to produce components. Constructed from hardened steel, pre-hardened steel, aluminium, and beryllium copper alloy. Steel molds are costly but offer longer lifespan. Manufactured by CNC machining or electrical discharge machining (EDM). Mould Design Considerations Shrinkage Allowance: Depends on material properties, core, and cavity size. Cooling Circuit: Water circulates through drilled holes in core and cavity plates to reduce cycle time. Ejection Gap: Gap between ejector plate face and core black plate face must hold dimension within the core and allow full removal of the component. Mould Polishing: Core, cavity, runner, and sprue should have a good surface finish, polished along material flow direction. Mould Filling: Gate placed to fill component from thicker to thinner section. Draft: Required in core and cavity for easy ejection. Mould Storage Custom molds are protected due to high costs. Maintained at perfect temperature and humidity to ensure longest lifespan. Rubber injection molds stored in controlled environments to prevent warping. Mould Cooling Constant mold temperature for uniform quality. Reduced cycle time, improved surface finish, longer mould life. Avoids warpage (distortion caused by non-uniform cooling). Injection Moulding Defects Blister: Thin film of plastic bubbles up from the surface. Flash: Excess plastic forms on the surface of the part. Burn marks: Discoloration due to overheating. Warping: Molded plastic part becomes distorted or deformed. Weld lines: Visible lines where plastic melt fronts meet. Cause: Melt enters cavity at high speed, touches surface, cures, then pushed by subsequent melt, leaving snaking marks. Solution: Reduce number of gates, adjust gate position, reduce mold release agents. Color streaks: Uneven color distribution. Voids: Empty spaces within the molded part. Advantages of Injection Moulding Fast production (5-60 seconds cycle time). Low labor costs, design flexibility, high output. Multiple materials can be used, very small parts produced. Good color control, product consistency, dimensional control. Reduced finishing requirements. Disadvantages of Injection Moulding High initial tooling and machinery cost. Part design restrictions. Small runs can be costly. 3. Blow Moulding Process Description Inflating a heated plastic tube (parison/preform) until it fills a mold. Thermoplastic resins are used. Parison is clamped between two mold halves and inflated by pressurized air. Pressure is about 25 to 150 psi. After cooling, mold halves separate, and part is ejected. Basic Blow Moulding Process Steps Melting of polymer $\rightarrow$ parison/preform formation $\rightarrow$ parison sealing $\rightarrow$ parison positioning $\rightarrow$ mould closing $\rightarrow$ shaping $\rightarrow$ product cooling $\rightarrow$ mould opening $\rightarrow$ finishing. Types of Polymer Moulding Extrusion blow moulding Injection blow moulding Injection stretch blow moulding Extrusion Blow Moulding Steps Heated plastic extruded into hollow tube (parison). Mold closes, parison gripped in place. Compressed air blown into parison, which inflates. Parison fills mold. Product trimmed and removed from mold. Finished product ready for next production stage. Injection Blow Moulding Steps Preform is injection molded around an injection mold. Injection mold is opened, preform transferred to blow mold. Soft polymer inflated to conform to blow mold. Blow mold opened, blown product removed. Injection Stretch Blow Moulding Steps Injection molded preform heated. Preform secured into blow mold. Preform stretched with core rod. Compressed air simultaneously blown in, preform shaped. Product removed from mold. Finished product ready for next production stage. Advantages of Blow Moulding Very fast production rate, quick product revisions. Easily replaceable parts, low maintenance. Process for hollow parts. Less expensive tooling than injection moulding. Excellent part performance under pressure. Trim and flash reusable. Applications of Blow Moulding Consumer Products: Edible oil/houseware containers, toys, furniture, cosmetic/shampoo bottles. Automotive: Car AC ducts, vehicle fuel tanks, panels, boots, covers. Medical & Pharmaceutical: IV fluid bottles, pouches for medicine, medicine bottles, healthcare equipment, protective devices. Chemical Industries: Small/large chemical containers, engine oil containers, catalyst drums. Cosmetics Packaging: Body lotion containers, shampoo bottles, moisturizer containers. Other Applications: Pesticides bottles, toilet cleaner bottles, food supplement bottles. 4. Compression Moulding Process Description Low-cost moulding method. High-pressure forming process: Molten plastic squeezed directly into mold cavity. Application of heat ($\ge 200^\circ C$) and pressure (10-150 MPa) to conform to mold shape. Thermoset plastics are manufactured. Mold remains hot throughout the cycle for thermosets (similar to closed die forging). Mould Designs Open flash: For shallow or flat parts. Slight excess of molding powder loaded into cavity. Flash formed as excess material is forced out, blocking plastic and exerting pressure on it. *Molding powder sinters and melts to form a protective liquid flux layer, trapping impurities. Fully positive: For high-density parts. No allowance for excess powder. Correctly measured charge must be used. Disadvantage: Gases from curing can be trapped, causing blisters. Semi-positive: Combines features of open flash and fully positive. Allows for excess powder and flash. Can have both horizontal and vertical flash. More expensive to manufacture/maintain but better for applications. Process Parameters Amount of plastic material (charge). Heating time. Melting temperature of plastic material. Pressure required to squeeze material into mold cavity. Cooling time. Materials Used Epoxy Urea Formaldehyde (UF) Polyester Polyamide (PI) Polyethylene (PE) Polypropylene (PP) Applications Electrical and electronic equipment. Brush and mirror handles, trays, cookware knobs, cooking utensils, dinnerware. Aircraft main power terminal housing. Automotive parts. Carbon fiber reinforced composite. Advantages Low initial setup cost and fast setup time. Heavy plastic parts can be molded. Good surface finish. Relatively little waste material. GRP (Glass Reinforced Polyester/Glassfibre Reinforced Plastics) Introduction Composite material, 30-60% glass fibers by volume in a polymer matrix. Fibers made by drawing molten glass through small orifices in a platinum die, then elongated, cooled, and wound. Glass fibers treated with silane for improved wetting and bonding. Components Polymer matrix (epoxy, vinylester, or polyester thermosetting resin): Provides environmental/chemical resistance, acts as binder, defines part form. Glass fibers: Add strength to composite, strong in tension. Can be randomly arranged or oriented. Plastic resins: Strong in compressive loading. GRP Characteristics Low weight, high mechanical strength. Resistance to chemicals and corrosion (non-conductive properties). UV radiation and temperature stability. Environmental friendliness, waterproof. Long lifetime expectancy. Production Methods Filament winding, centrifugal casting, hand lay-up, spray lay-up. Pultrusion: Manufacturing process pulling continuous fibers through a resin bath and then a heated die. GRP Mould Process Batching: Weighing and mixing materials. Melting: Heating mixture to high temperature. Fiberization: Extruding molten glass through bushing to create strands. Coating: Applying chemical coating to glass strands. Reinforcing: Adding glass fibers (chopped, long, or woven) to resin matrix. Curing: Catalyst initiates chemical reaction to harden resin. Cutting: Using traveling cut-off saw to cut Fiber Reinforced Plastic. Trimming, painting, and polishing: Removing from mold, finishing. Different Types of GRP E-type: Calcium aluminoborosilicate glass, most commonly used. S-type: Magnesia aluminosilicate glass, higher strength and stiffness, but higher cost. E-CR-type: High-performance glass fiber, higher resistance to elevated temperatures and acid corrosion. GRP Applications Outdoor applications Aerospace Automotive Marine Construction industries