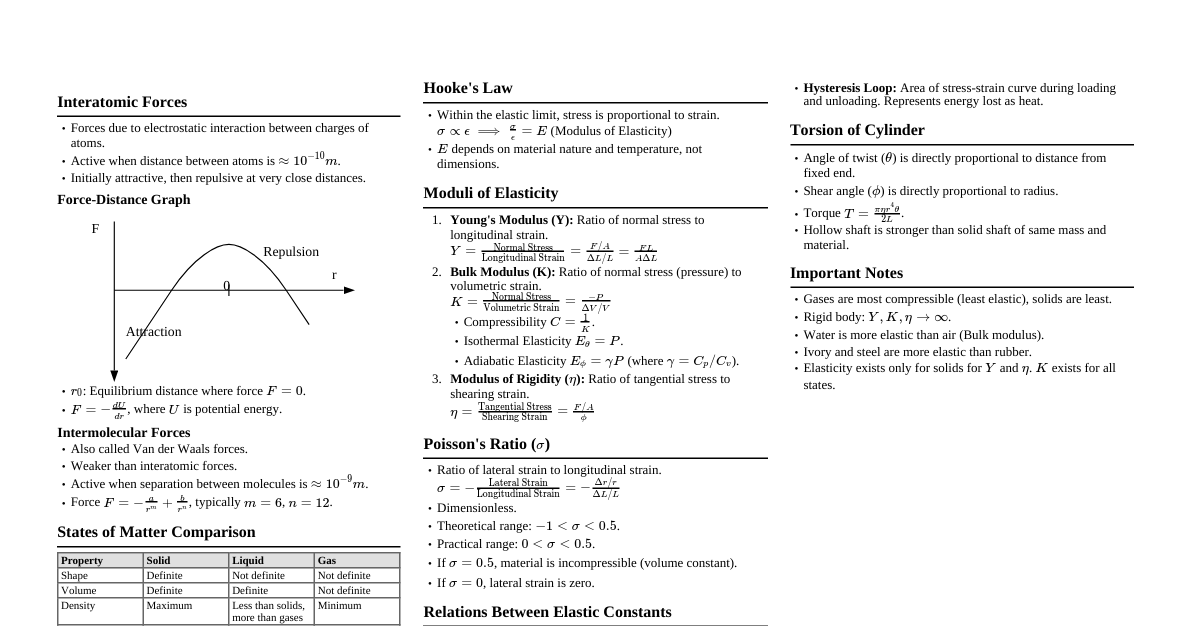

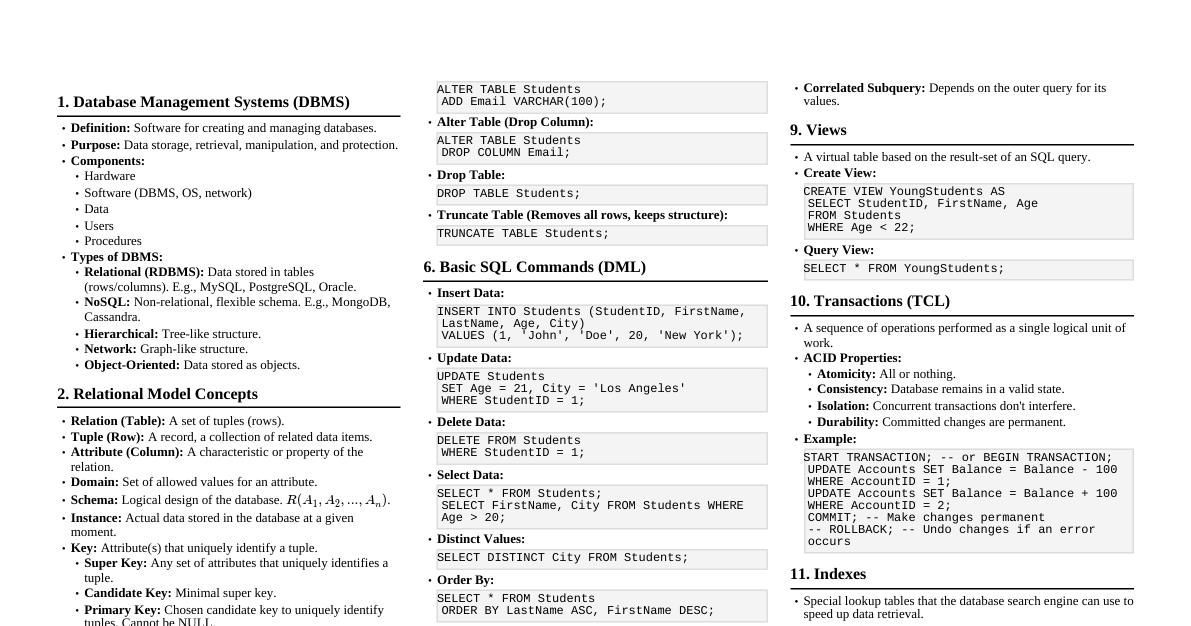

Deforming Force A force that changes the size or shape of a body. When a deforming force is applied, the body undergoes deformation. Elastic Limit The maximum stress a material can withstand without undergoing permanent deformation. Beyond this limit, the material will not return to its original shape after the deforming force is removed. Stress ($\sigma$) Definition: Internal restoring force developed per unit area of cross-section of the body. Formula: $\sigma = \frac{\text{Restoring Force}}{\text{Area}} = \frac{F}{A}$ SI Unit: Pascal (Pa) or $N/m^2$. Types of Stress: Normal Stress: Perpendicular to the surface. Longitudinal Stress: When force is applied along the length (e.g., stretching a wire). Tensile Stress: When length increases. Compressive Stress: When length decreases. Bulk or Volume Stress: When force is applied uniformly and perpendicularly over the entire surface, changing volume. Tangential or Shearing Stress: Parallel to the surface, causing a change in shape. Strain ($\epsilon$) Definition: The ratio of the change in configuration (length, volume, or shape) to the original configuration. It is a dimensionless quantity. Types of Strain: Longitudinal Strain: $\epsilon_L = \frac{\Delta L}{L}$ (Change in length / Original length) Volumetric Strain: $\epsilon_V = \frac{\Delta V}{V}$ (Change in volume / Original volume) Shearing Strain: $\epsilon_S = \theta$ (Angle of shear, measured in radians). $\theta = \frac{\text{Relative displacement of parallel face}}{\text{Distance between parallel faces}} = \frac{\Delta x}{L}$ Hooke's Law Statement: Within the elastic limit, stress is directly proportional to strain. Formula: $\sigma \propto \epsilon \implies \sigma = E \cdot \epsilon$ $E$ is the modulus of elasticity, a constant for a given material. Modulus of Elasticity ($E$) Definition: The ratio of stress to strain within the elastic limit. SI Unit: Pascal (Pa) or $N/m^2$. Types of Moduli: Young's Modulus ($Y$): For longitudinal stress and strain. $Y = \frac{\text{Longitudinal Stress}}{\text{Longitudinal Strain}} = \frac{F/A}{\Delta L/L} = \frac{FL}{A\Delta L}$ Relevant for solids and describes resistance to change in length. Bulk Modulus ($B$): For bulk stress and volumetric strain. $B = \frac{\text{Bulk Stress}}{\text{Volumetric Strain}} = \frac{-P}{\Delta V/V} = \frac{-PV}{\Delta V}$ The negative sign indicates that an increase in pressure ($P$) causes a decrease in volume ($\Delta V$). Compressibility ($K$): Reciprocal of Bulk Modulus, $K = \frac{1}{B}$. Relevant for solids, liquids, and gases. Shear Modulus or Modulus of Rigidity ($G$ or $\eta$): For tangential stress and shearing strain. $G = \frac{\text{Tangential Stress}}{\text{Shearing Strain}} = \frac{F_t/A}{\theta} = \frac{F_t}{A\theta}$ Relevant for solids and describes resistance to change in shape. Poisson's Ratio ($\nu$) Definition: Within the elastic limit, the ratio of lateral strain to longitudinal strain. Formula: $\nu = \frac{\text{Lateral Strain}}{\text{Longitudinal Strain}} = \frac{-\Delta D/D}{\Delta L/L}$ (for a cylinder of diameter $D$ and length $L$) It is a dimensionless quantity. The negative sign indicates that if a material is stretched longitudinally, its diameter decreases. Limiting Values: Theoretically, $-1 \le \nu \le 0.5$. Practically, $0 \le \nu \le 0.5$. Most materials have $\nu$ between 0.2 and 0.4. For an incompressible material, $\nu = 0.5$. For a perfectly rigid body, $\nu = 0$. Relation between Shear Angle and Angle of Twist (for a cylindrical rod) Consider a cylindrical rod of length $L$ and radius $R$ fixed at one end and twisted by an angle $\phi$ (angle of twist) at the other end. The shear strain ($\theta$) at the surface of the rod is given by: $\theta = \frac{R\phi}{L}$ This relates the angle of twist ($\phi$) of the entire cylinder to the shear angle ($\theta$) experienced by elements on its surface. Torque Required for Twisting a Cylinder (Torsion) When a cylindrical rod of length $L$ and radius $R$ is twisted by an angle $\phi$, a restoring torque is generated. This restoring torque ($\tau$) is proportional to the angle of twist $\phi$. Formula: $\tau = \frac{\pi G R^4}{2L} \phi = C \phi$ Where: $\tau$ is the twisting torque. $G$ is the shear modulus (modulus of rigidity) of the material. $R$ is the radius of the cylinder. $L$ is the length of the cylinder. $\phi$ is the angle of twist in radians. $C = \frac{\pi G R^4}{2L}$ is the torsional rigidity or torsional constant of the rod. This torque is also known as the couple per unit twist. Important Relationships between Elastic Moduli $Y = 3B(1 - 2\nu)$ $Y = 2G(1 + \nu)$ $\frac{9}{Y} = \frac{3}{G} + \frac{1}{B}$ or $Y = \frac{9BG}{3B+G}$