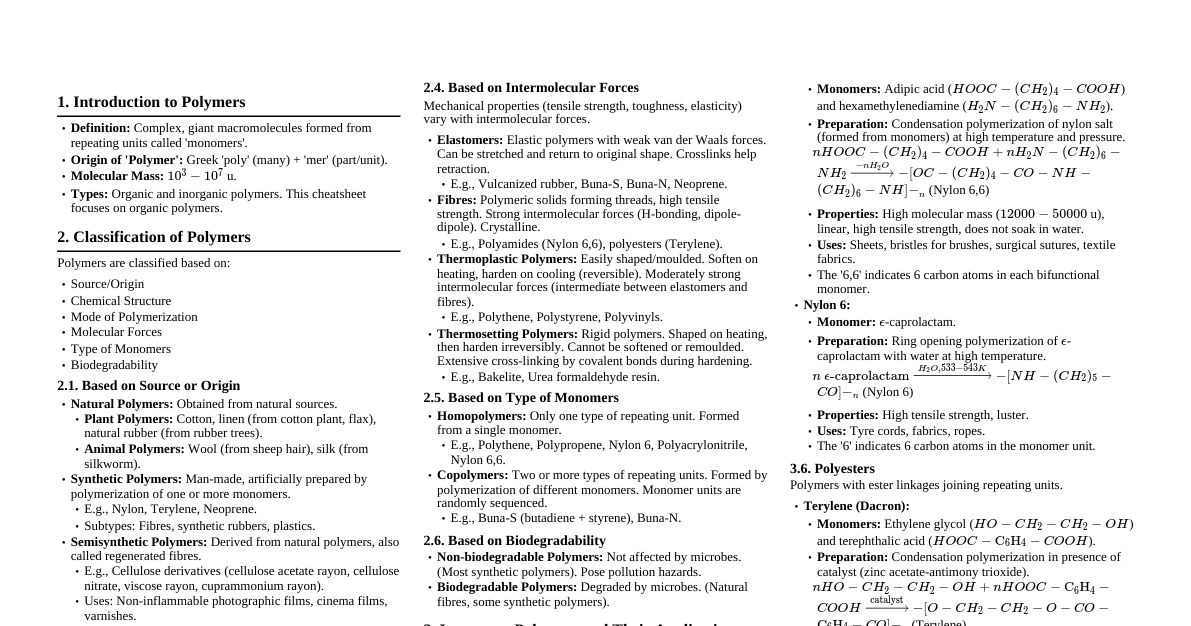

1. Polymers and Monomers Polymers: Macromolecules formed by repeated linking of small molecules (monomers). Monomers: Small molecules that combine to form a polymer. 2. Degree of Polymerization ($n$) The number of repeating units in a polymer chain. Calculated as: $n = \frac{\text{Molecular weight of the polymeric network}}{\text{Molecular weight of the repeating unit}}$ 3. Polymerization Process where small molecules (monomers) combine to form a large molecule (polymer), with or without elimination of small molecules (e.g., water). 4. Types of Polymerization Addition Polymerization Condensation Polymerization Copolymerization 5. Dead Polymer The stable product formed from addition polymerization, where chain growth has terminated. 6. High Polymers Polymers with a high degree of polymerization, typically having molecular weights from $10,000$ to $200,000$. Examples (plastic and fiber): PVC, Polyurethane. 7. Simple Polymer vs. Copolymer Feature Simple Polymer Copolymer Monomers Formed from only one type of monomer (e.g., PVC) Formed from more than one type of monomer (e.g., Butadiene styrene polymer) Molecular Weight Lower Higher 8. Polyvinyl Chloride (PVC) Repeating Unit: $-(\text{CH}_2-\text{CH}(\text{Cl}))-$ Uses: Pipes, cable insulations, table covers, raincoats. 9. Nylon 6,6 Formation: Polymerization of adipic acid with hexamethylenediamine. Properties: Translucent, white, horn-like material, high temperature stability, good abrasion resistance. Uses: Fibers for socks, dresses, carpets. $$ n \text{ H}_2\text{N}-(\text{CH}_2)_6-\text{NH}_2 + n \text{ HOOC}-(\text{CH}_2)_4-\text{COOH} \xrightarrow{\text{Polymerization}} \text{H}-[\text{HN}-(\text{CH}_2)_6-\text{NH}-\text{CO}-(\text{CH}_2)_4-\text{CO}]_n-\text{OH} + (2n-1)\text{H}_2\text{O} $$ 10. Addition vs. Condensation Polymerization Feature Addition (Chain) Polymerization Condensation (Step) Polymerization Monomer requirement At least one multiple bond At least two identical or different functional groups By-products No by-products formed By-products formed (e.g., $\text{H}_2\text{O}$, $\text{CH}_3\text{OH}$) Monomer units Decreases steadily throughout Disappear at early stage Polymer MW Integral multiple of monomer MW Need not be integral multiple of monomer MW Polymer formation High MW polymer formed at once MW rises steadily throughout Reaction time & MW Longer time for higher yield, little effect on MW Longer time essential for high MW Products Thermoplastics (e.g., polyethylene, PVC) Thermosetting plastics (e.g., Bakelite, urea-formaldehyde) Chain type Homo-chain polymers Hetero-chain polymers 11. Fluon (Teflon / PTFE) Formation: Polymerization of tetrafluoroethylene ($\text{CF}_2=\text{CF}_2$) in water emulsion with benzoyl peroxide. Properties: Extremely tough, flexible, high softening point ($350^\circ\text{C}$), good electrical/mechanical properties, chemically resistant (except hot alkali metals/fluorine), excellent thermal stability. Uses: Electrical insulation (motors, cables), gaskets, packings, pump parts, tank linings, non-lubricating bearings, chemical pipes, non-stick stopcocks. $$ n \text{CF}_2=\text{CF}_2 \xrightarrow{(\text{C}_6\text{H}_5)_2\text{O}_2} -[\text{CF}_2-\text{CF}_2]_n- $$ 12. Plastics High molecular weight organic materials moldable into desired shapes by heat and pressure, often with a catalyst. 13. Thermoplastics vs. Thermosetting Plastics Feature Thermoplastics Thermosetting Plastics Formation Addition polymerization Condensation polymerization Structure Linear long-chain polymers Three-dimensional network structure Chain bonding Weak Van der Waals forces Strong covalent bonds Strength/Brittleness Weak, soft, less brittle Strong, hard, more brittle Heating effect Soften on heating, harden on cooling Do not soften on heating Remolding Can be remolded Cannot be remolded Molecular Weight Low High Solubility Soluble in organic solvents Insoluble in organic solvents Example Polyethylene Bakelite 14. Polycarbonate Applications: Electrical insulators, housing apparatus, plugs, sockets, switches, transparent containers, camera/photographic films, hair-drier bodies, baby bottles, safety windows. 15. Elastomers (Rubbers) Non-crystalline high polymers (linear polymers) with elastic and rubber-like properties. 16. Drawbacks of Raw Rubber Plastic nature: soft at high temperatures, brittle at low temperatures. Poor strength. Large water-absorption capacity. Non-resistant to non-polar solvents (benzene, vegetable & mineral oils). Attacked by oxidizing agents ($\text{HNO}_3$, $\text{H}_2\text{SO}_4$). Swells and disintegrates in organic solvents. Little durability. 17. Vulcanization of Rubber Process of heating raw rubber with sulfur (typically $100-140^\circ\text{C}$) to improve its properties by forming cross-links. 18. Natural Rubber Structure $$ \text{...}-\text{CH}_2-\text{C}(\text{CH}_3)=\text{CH}-\text{CH}_2-\text{CH}_2-\text{C}(\text{CH}_3)=\text{CH}-\text{CH}_2-\text{...} $$ 19. Natural Rubber Origin Obtained from the tree as latex, a dispersion of isoprene. 20. Butyl Rubber Characteristics Amorphous under normal conditions. Unstabilized polyisobutylenes degrade by light/heat to sticky low MW products. Low permeability to gases. Soluble in hydrocarbon solvent. Good electrical insulating properties and resistance to heat and abrasion. 21. Polycarbonate Uses Polyethers of phenol and carbonic acid. Uses: Molded domestic wares, telephone parts, insulator electrical parts. 22. Thermoplastics Obtained by addition polymerization. Polymer chains held by weak Van der Waals forces. Soften on heating, harden on cooling. Soluble in organic solvents. 23. Addition Polymers Reaction yields a polymer that is an exact multiple of the original monomeric molecule. Monomer usually contains one or more double bonds. No elimination of molecules during polymerization. Example: Polyethylene from ethylene. $$ n \text{CH}_2=\text{CH}_2 \xrightarrow{\text{Heat/pressure}} -[\text{CH}_2-\text{CH}_2]_n- $$ 24. Copolymerization Joint polymerization where two or more different monomers combine to give a polymer. Example: Butadiene and styrene copolymerize to form GR-S rubber. $$ n[\text{CH}_2=\text{CH}-\text{CH}=\text{CH}_2] + n\text{CH}_2=\text{CH}-\text{C}_6\text{H}_5 \xrightarrow{\text{Copolymerization}} -[\text{CH}_2-\text{CH}=\text{CH}-\text{CH}_2-\text{CH}_2-\text{CH}(\text{C}_6\text{H}_5)]_n- $$ 25. Condensation Polymerization Reaction between simple polar groups containing monomers, forming a polymer and eliminating small molecules (e.g., $\text{H}_2\text{O}$, $\text{HCl}$). Example: Hexamethylenediamine and adipic acid condense to form Nylon 6,6. 26. Polymer Classification (by source) Natural polymers Synthetic polymers 27. Copolymers High molecular weight polymers obtained by joint polymerization of two or more different monomers. 28. Composites A material system consisting of a mixture of two or more micro-constituents that are mutually insoluble, differing in form or composition, and forming distinct phases. 29. Constituents of Composites Matrix phase (or) matrix resin Dispersed phase (or) reinforcement 30. Matrix Phase Continuous body constituent enclosing the composite. Can be metals, ceramics, or polymers (liquid resins). 31. Cure Reaction Formation of cross-linking in certain polymers. Done using a curing agent. Uncross-linked polymers contain functional groups or double bonds. 32. Reinforcement Process of improving plastic matrix characteristics by adding reinforcing agents. Reinforcing agents can be organic or inorganic, in powder, flake, or fiber form. 33. Needs of Composites No rust, less fracture toughness than metals. Reduced maintenance cost, long-term stability. Increased power/data transmission in telecommunications. Lower weight, reduces fuel consumption and emissions. Stronger and stiffer. 34. Characteristics of Composites Higher specific strength and lower specific gravity. Lower electrical conductivity and thermal expansion. Better creep, fatigue strength, corrosion, and oxidation resistance. Maintain good strength at high temperatures. 35. Characteristics of FRP (Fiber Reinforced Polymers) Superior properties: higher yield strength, fracture strength, fatigue life. Fiber prevents slip and crack propagation, increasing mechanical properties. High corrosion resistance and heat resistance. 36. Raw Rubber vs. Vulcanized Rubber S.No Property Raw Rubber Vulcanized Rubber 1 Tensile Strength Low ($200 \text{ kg/cm}^2$) High ($2000 \text{ kg/cm}^2$) 2 Water Absorption High Low 3 Oxidation Resistance Low High 4 Durability Little High 5 Wear and Tear Resistance Low High 6 Elongation High ($1200\%$) Moderate ($800\%$) 7 Useful Temperature Range $10 - 60^\circ\text{C}$ $40 - 100^\circ\text{C}$ 8 Resistance to Organic Solvents Attacked Resistant 37. Butyl Rubber Preparation, Properties, and Uses Preparation: Copolymerization of isobutylene and a small amount of isoprene using $\text{AlCl}_3$ catalyst. Properties: Amorphous, low gas permeability, soluble in hydrocarbon solvents, good electrical insulator, resistant to heat and abrasion. Uses: Tubes, hoses, conveyor belts, wire and cable insulation. $$ n \text{CH}_2=\text{C}(\text{CH}_3)_2 + n \text{CH}_2=\text{C}(\text{CH}_3)-\text{CH}=\text{CH}_2 \xrightarrow{\text{co-polymerization}} -[\text{CH}_2-\text{C}(\text{CH}_3)_2-\text{CH}_2-\text{C}(\text{CH}_3)=\text{CH}-\text{CH}_2]_n- $$ 38. Composites and Their Constituents Definition: Material system with a mixture of two or more mutually insoluble micro-constituents with distinct phases. Constituents: Matrix Phase (Matrix Resin): Continuous body constituent that encloses the composite. Can be metals, ceramics, or polymers (liquid resins). Dispersed Phase (Reinforcement): Structural constituent determining internal structure (fibers, particulates, flakes, whiskers). Types of Matrixes: Metal Matrix Composites (MMC), Ceramic Matrix Composites (CMC), Polymer Matrix Composites (PMC). Liquid Resins: Polymers used as adhesives, potting compounds, sealants in liquid form. Examples: Epoxy adhesives, polysulphides. Cure Reactions: Formation of cross-linking in polymers using a curing agent. Uncross-linked linear polymers with functional groups or double bonds are called prepolymers. 39. Purpose of Matrix and Reinforcement Purpose of Matrix: Binds fiber reinforcement and transfers loads between fibers. Gives net shape to composites. Determines surface quality. Purpose of Reinforcement: Increases overall mechanical characteristics of the matrix. Provides strength and stiffness. Increases coefficient of thermal expansion and conductivity. 40. FRP (Fiber Reinforced Polymer) Composites Constitute over $90\%$ (by weight) of total composites used in industries. Advantages: Easy fabrication of complex shapes. Preparation: Bonding fiber material with resin matrix, then curing under pressure and heat. Reinforcing Agents: Glass, graphite, alumina, carbon, boron. Forms: short fibers, continuous filaments, woven fabrics. Resin Matrixes: Polyesters, epoxy, phenolic, silicone, polyamide. Characteristics: High yield strength, fracture strength, fatigue life. Fiber prevents slip/crack propagation. High corrosion/heat resistance. Properties depend on resin matrix. Resin Type Reason Polyester resin Good strength and mechanical properties Epoxy resin Good mechanical properties Silicone resins Excellent thermal and electrical properties Phenolic resins Withstand high temperature Thermoplastics (polyamide, PET) Repeatability and repairability 41. Types of FRP Composites Name of FRP Properties Applications Glass - FRP Lower densities, dielectric constants. Higher tensile strength and impact resistance. Excellent corrosion, chemical resistance, non-flammability. Automobile parts, storage tanks, plastic pipes, flooring, transportation industries. Boron - FRP Excellent stiffness and compressive strength. Difficult to manufacture. Horizontal and vertical tail in aeroplanes, stiffening spares, ribs. Carbon - FRP Lighter density. Excellent resistance to corrosion. Retention of properties at elevated temperatures. Structural components of aircraft, helicopters, recreational equipment, sports materials, antenna discs, solar panels. Aramid - FRP Metal-like ductile, responds non-catastrophically to compressive stresses (due to energy absorption). Structural component in aircraft, helicopter parts. Alumina - FRP Good abrasion resistance, creep resistance, dimensional stability. Components of engine parts in automobile industry, turbine engine. Fibre reinforced laminates High impact protection. Lower smoke/flame spread ability. Strength 13 times higher than rigid vinyl surface. Increase strength of reinforced concrete and pre-tensioned structures. Controls and prevents cracking in plastic area of members. 42. Advantages of Polymer Composites (FRP) High strength-to-weight ratio compared to metal. $75\%$ lower weight than steel, improving performance, reducing energy, simplifying handling. Reduced capacitance and leakage current in devices. Better corrosion resistance, leading to longer service life, less maintenance. Excellent durability and fire-resisting properties. Ideal for outdoor installation, impervious to sunlight, heat, cold. Orienting reinforcing fibers can increase strength and resistance to deformation. GRP (glass reinforced polymer) is stronger and more resistive to deforming forces when fibers are parallel to the force. CRP (carbon fiber reinforced polymer) in place of sheet aluminium: $25\%$ reduction in weight. $95\%$ reduction in components by combining parts and forming simpler molded parts.