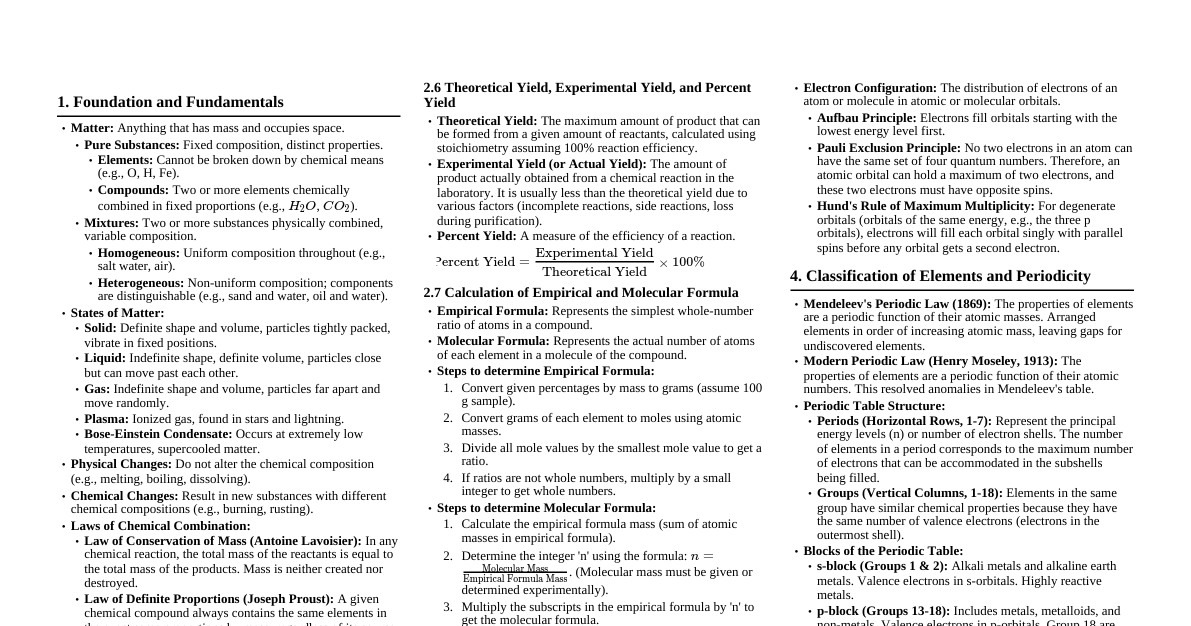

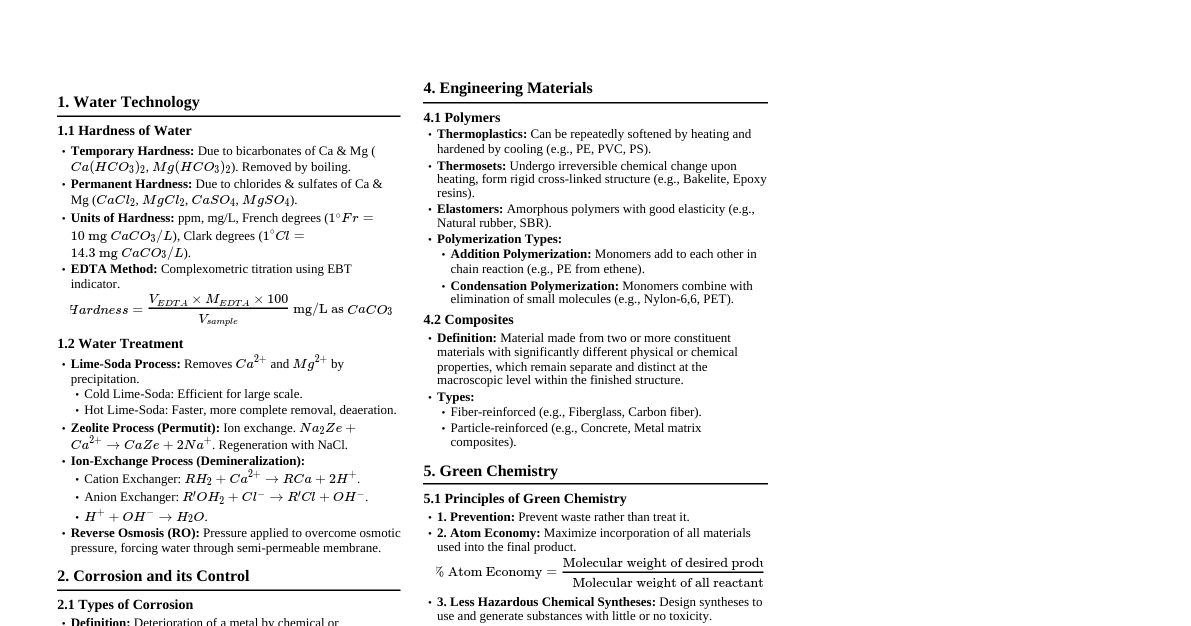

1. Introduction to Polymers Definition: Complex, giant macromolecules formed from repeating units called 'monomers'. Origin of 'Polymer': Greek 'poly' (many) + 'mer' (part/unit). Molecular Mass: $10^3 - 10^7$ u. Types: Organic and inorganic polymers. This cheatsheet focuses on organic polymers. 2. Classification of Polymers Polymers are classified based on: Source/Origin Chemical Structure Mode of Polymerization Molecular Forces Type of Monomers Biodegradability 2.1. Based on Source or Origin Natural Polymers: Obtained from natural sources. Plant Polymers: Cotton, linen (from cotton plant, flax), natural rubber (from rubber trees). Animal Polymers: Wool (from sheep hair), silk (from silkworm). Synthetic Polymers: Man-made, artificially prepared by polymerization of one or more monomers. E.g., Nylon, Terylene, Neoprene. Subtypes: Fibres, synthetic rubbers, plastics. Semisynthetic Polymers: Derived from natural polymers, also called regenerated fibres. E.g., Cellulose derivatives (cellulose acetate rayon, cellulose nitrate, viscose rayon, cuprammonium rayon). Uses: Non-inflammable photographic films, cinema films, varnishes. 2.2. Based on Structure Monomer linking determines chain configuration: Linear or Straight Chain Polymers: Monomer molecules joined in a linear arrangement. Obtained from bifunctional monomers or alkenes. E.g., PVC, high density polythene. Branched Chain Polymers: Monomers with 3 functional groups or side chains give rise to branched chains. E.g., Low density polythene. Cross-linked Polymers (Network Polymers): Cross-links produced between linear chains. Results from polyfunctional monomers. E.g., Bakelite, Melamine. 2.3. Based on Mode of Polymerization Process by which low molecular mass compounds convert to high molecular weight compounds by linking repeating structural units with covalent bonds. Addition Polymerization (Chain Growth Polymerization): Monomers add without loss of small molecules. Repeating unit has same elemental composition as original monomer. Monomers with double bonds undergo addition polymerization (vinyl polymerization). E.g., Polyethylene from ethylene ($CH_2=CH_2$). Mechanism (Free Radical): Chain Initiation: Initiated by a free radical (R•) from catalysts (benzoyl peroxide, etc.). $R• + CH_2=CHY \rightarrow R-CH_2-CHY•$ (new radical) Chain Propagation: New radical reacts with more monomer molecules to form bigger radicals. $R-CH_2-CHY• + nCH_2=CHY \rightarrow R-(CH_2-CHY)_n-CH_2-CHY•$ Chain Termination: Growing chains terminate, e.g., by combination of two radicals. $2 R-(CH_2-CHY)_n-CH_2-CHY• \rightarrow R-(CH_2-CHY)_{2n+2}-R$ (polymer) Condensation Polymerization (Step Growth Polymerization): Monomers combine with elimination of small molecules (e.g., water, HCl, methanol, ammonia). Chain growth occurs by a series of condensation steps. E.g., Terylene (Polyester) from ethylene glycol and terephthalic acid. $n HO-CH_2-CH_2-OH + n HOOC-\text{C}_6\text{H}_4-COOH \xrightarrow{-nH_2O} \text{Polymer}$ Repeating units of condensation polymer do not have the same elemental composition as that of monomer. Ring Opening Polymerization: Cyclic compounds (lactams, cyclic ethers, lactones) polymerize by ring opening. Catalyzed by strong acid/base. E.g., Polymerization of $\epsilon$-caprolactam to Nylon 6. Elemental composition of repeating unit is same as monomers (like addition polymerization). Proceeds by addition of single monomer unit to growing chain (step growth). Example: Nylon 6 from $\epsilon$-caprolactam. NH C=O -(CH2)5- $n \text{ } \epsilon\text{-caprolactam} \xrightarrow{H_2O, 533-543K} -[NH-(CH_2)_5-CO]-_n$ (Nylon 6) 2.4. Based on Intermolecular Forces Mechanical properties (tensile strength, toughness, elasticity) vary with intermolecular forces. Elastomers: Elastic polymers with weak van der Waals forces. Can be stretched and return to original shape. Crosslinks help retraction. E.g., Vulcanized rubber, Buna-S, Buna-N, Neoprene. Fibres: Polymeric solids forming threads, high tensile strength. Strong intermolecular forces (H-bonding, dipole-dipole). Crystalline. E.g., Polyamides (Nylon 6,6), polyesters (Terylene). Thermoplastic Polymers: Easily shaped/moulded. Soften on heating, harden on cooling (reversible). Moderately strong intermolecular forces (intermediate between elastomers and fibres). E.g., Polythene, Polystyrene, Polyvinyls. Thermosetting Polymers: Rigid polymers. Shaped on heating, then harden irreversibly. Cannot be softened or remoulded. Extensive cross-linking by covalent bonds during hardening. E.g., Bakelite, Urea formaldehyde resin. 2.5. Based on Type of Monomers Homopolymers: Only one type of repeating unit. Formed from a single monomer. E.g., Polythene, Polypropene, Nylon 6, Polyacrylonitrile, Nylon 6,6. Copolymers: Two or more types of repeating units. Formed by polymerization of different monomers. Monomer units are randomly sequenced. E.g., Buna-S (butadiene + styrene), Buna-N. 2.6. Based on Biodegradability Non-biodegradable Polymers: Not affected by microbes. (Most synthetic polymers). Pose pollution hazards. Biodegradable Polymers: Degraded by microbes. (Natural fibres, some synthetic polymers). 3. Important Polymers and Their Applications 3.1. Natural Rubber (Polyisoprene) Monomer: Isoprene (2-methyl-1,3-butadiene). $CH_2=C(CH_3)-CH=CH_2$ (Isoprene) Structure: High molecular mass linear polymer of isoprene. Molecular mass: $130,000$ u to $340,000$ u. Properties: Cis configuration of C=C double bonds, weak van der Waals forces, coiled structure, elastic. Vulcanization: Process to improve physical properties (tensile strength, stiffness, elasticity, toughness). Heating raw rubber with sulfur (and accelerators like ZBX) at $150^\circ C$. Sulfur forms cross-links between polyisoprene chains. Increasing sulfur content (40-45%) yields ebonite (hard, non-elastic). 3.2. Polythene (Polyethylene) Simplest and most common hydrocarbon thermoplastic: $-[CH_2-CH_2]-_n$. Low Density Polyethylene (LDP): Preparation: Polymerization of ethylene ($CH_2=CH_2$) under high pressure ($1000-2000$ atm) and temperature ($350-570$ K) with traces of $O_2$ or peroxide initiator. Mechanism: Free radical addition and H-atom abstraction (leading to branching). Properties: Flexible, tough, chemically inert, moisture resistant, poor electrical conductor, low density (chains loosely held). Melting point $110^\circ C$. Uses: Pipes for agriculture/irrigation, domestic water lines, electrical cable insulation, extruded films, sheets, packaging, squeeze bottles. High Density Polyethylene (HDP): Preparation: Polymerization of ethene ($CH_2=CH_2$) in presence of Ziegler-Natta catalyst (triethyl aluminium + titanium tetrachloride) at $333-343$ K and $6-7$ atm. Properties: Crystalline, stiffer than LDP, high tensile strength, hardness, more chemical resistance, high density (close packing). Melting point $144-150^\circ C$. Uses: Toys, buckets, dustbins, bottles, pipes, laboratory wares, objects requiring high tensile strength/stiffness. 3.3. Teflon (Polytetrafluoroethylene) Monomer: Tetrafluoroethylene ($CF_2=CF_2$). Preparation: Polymerization using free radical initiators (hydrogen peroxide, ammonium persulphate) at high pressure. $n CF_2=CF_2 \xrightarrow{\text{Polymerization}} -[CF_2-CF_2]-_n$ (Teflon) Properties: Tough, chemically inert, resistant to heat and corrosive reagents. C-F bond is very difficult to break. Uses: Non-stick cookware, oil seals, gaskets. 3.4. Polyacrylonitrile (PAN) Monomer: Acrylonitrile ($CH_2=CHCN$). Preparation: Addition polymerization using peroxide initiator. $n CH_2=CHCN \xrightarrow{\text{Peroxide}} -[CH_2-CH(CN)]-_n$ (Polyacrylonitrile) Properties: Resembles wool. Uses: Wool substitute, Orlon, Acrilan (blankets, sweaters). 3.5. Polyamide Polymers (Nylons) Contain -CO-NH- (amide) groups as inter-unit linkages. Obtained by condensation polymerization of dicarboxylic acids and diamines, or self-condensation of amino acids, or ring-opening of lactams. Nylon 6,6: Monomers: Adipic acid ($HOOC-(CH_2)_4-COOH$) and hexamethylenediamine ($H_2N-(CH_2)_6-NH_2$). Preparation: Condensation polymerization of nylon salt (formed from monomers) at high temperature and pressure. $n HOOC-(CH_2)_4-COOH + n H_2N-(CH_2)_6-NH_2 \xrightarrow{-nH_2O} -[OC-(CH_2)_4-CO-NH-(CH_2)_6-NH]-_n$ (Nylon 6,6) Properties: High molecular mass ($12000-50000$ u), linear, high tensile strength, does not soak in water. Uses: Sheets, bristles for brushes, surgical sutures, textile fabrics. The '6,6' indicates 6 carbon atoms in each bifunctional monomer. Nylon 6: Monomer: $\epsilon$-caprolactam. Preparation: Ring opening polymerization of $\epsilon$-caprolactam with water at high temperature. $n \text{ } \epsilon\text{-caprolactam} \xrightarrow{H_2O, 533-543K} -[NH-(CH_2)_5-CO]-_n$ (Nylon 6) Properties: High tensile strength, luster. Uses: Tyre cords, fabrics, ropes. The '6' indicates 6 carbon atoms in the monomer unit. 3.6. Polyesters Polymers with ester linkages joining repeating units. Terylene (Dacron): Monomers: Ethylene glycol ($HO-CH_2-CH_2-OH$) and terephthalic acid ($HOOC-\text{C}_6\text{H}_4-COOH$). Preparation: Condensation polymerization in presence of catalyst (zinc acetate-antimony trioxide). $n HO-CH_2-CH_2-OH + n HOOC-\text{C}_6\text{H}_4-COOH \xrightarrow{\text{catalyst}} -[O-CH_2-CH_2-O-CO-\text{C}_6\text{H}_4-CO]-_n$ (Terylene) Properties: High melting point ($265^\circ C$), resistant to chemicals and water. Uses: Wrinkle-free fabrics (blending with cotton/wool), glass reinforcing materials (safety helmets). PET (polyethyleneterephthalate) is a common thermoplastic used for bottles, jars, packaging. Polycarbonates: Also polyester polymers, high melting thermosetting resins. 3.7. Phenol-Formaldehyde Polymers (Bakelite) Monomers: Phenol and Formaldehyde. Preparation: Phenol and formaldehyde react (acid/base catalyst) to form ortho and para hydroxyl methyl phenols. These condense to form linear Novolac (thermosetting/moulding powder). Novolac is shaped in moulds and heated ($138-176^\circ C$) under pressure, forming extensive cross-links to yield rigid Bakelite. Properties: Insoluble, infusible, high tensile strength, rigid. Uses: Telephone instruments, kitchenware, electric insulators. 3.8. Melamine-Formaldehyde Polymer Monomers: Melamine and Formaldehyde. Preparation: Condensation polymerization to give cross-linked melamine formaldehyde resin. Uses: Decorative table tops (Formica), plastic dinnerware (heat/moisture resistant thermosetting plastic). 3.9. Buna-S Rubber (SBR) Type: Elastomer, copolymer. Monomers: Butadiene (75 parts) and Styrene (25 parts). Preparation: Addition polymerization by action of sodium. Properties: Superior to natural rubber in mechanical strength and abrasion resistance. Uses: Tyre industry. 3.10. Neoprene (Polychloroprene) Type: Synthetic rubber, condensation polymer (despite text saying "condensation polymer", it's generally considered an addition polymer of chloroprene). Monomer: Chloroprene (2-chloro-1,3-butadiene). $n CH_2=C(Cl)-CH=CH_2 \xrightarrow{\text{Polymerization}} -[CH_2-C(Cl)=CH-CH_2]-_n$ (Neoprene) Preparation: Rapid polymerization in presence of oxygen. Vulcanization: In presence of magnesium oxide. Properties: Resistant to petroleum, vegetable oils, light, heat. Uses: Hose pipes (for gasoline), gaskets, insulator cables, jackets, belts. 3.11. Viscose Rayon Type: Semisynthetic fibre, regenerated cellulose. Monomer: Glucose units (from wood pulp cellulose). Preparation: Wood pulp cellulose is treated with concentrated NaOH (fluffy alkali cellulose), then carbon disulphide (xanthate), then dilute NaOH (viscose solution), extruded through spinnerets into acid bath to precipitate regenerated cellulose fibres. 4. Molecular Mass and Degree of Polymerization (DP) Polymers are mixtures of molecules with different molecular masses. Molecular mass is an average of constituent molecules. DP is the number of monomer units in a polymer molecule. Polymer properties depend on molecular mass; must be above a critical DP for desired properties. For polymers with H-bonding, critical DP is lower than for those with weak intermolecular forces. 5. Biodegradable Synthetic Polymers Developed to tackle environmental pollution caused by non-biodegradable synthetic polymers. Contain functional groups similar to those in biopolymers (e.g., proteins). Aliphatic polyesters and polyamides with polar linkages are important classes. PHBV (Poly-$\beta$-hydroxybutyrate-co-$\beta$-hydroxyvalerate): Type: Copolymer, aliphatic polyester. Monomers: $\beta$-hydroxybutyric acid (3-hydroxybutanoic acid) and $\beta$-hydroxyvaleric acid (3-hydroxypentanoic acid). Preparation: Hydroxyl group of one monomer forms ester link with carboxyl group of the other. $n HO-CH(CH_3)-CH_2-COOH + n HO-CH(CH_2CH_3)-CH_2-COOH \xrightarrow{-nH_2O} \text{PHBV}$ Properties: Degraded by microbes. Nylon 2 - Nylon 6: Type: Polyamide copolymer. Monomers: Glycine and $\epsilon$-amino caproic acid. Properties: Biodegradable. 6. Commercially Important Polymers (Table Summary) Trade Name Monomer Polymer Structure (Simplified) Applications Perspex/Acrylic glass Methyl methacrylate $-[CH_2-C(CH_3)(COOMe)]-_n$ Lenses, paint, security barrier, LCD screen, shatter resistant glass Buna N Butadiene and acrylonitrile $-[CH_2-CH=CH-CH_2-CH(CN)-CH_2]-_n$ Adhesives, rubber belts, shoe soles, O-rings, gaskets PVC (Polyvinyl chloride) Vinyl chloride $-[CH_2-CH(Cl)]-_n$ Water pipes, rain coats, flooring Polyacrylamide Acrylamide $-[CH_2-CH(CONH_2)]-_n$ Polyacrylamide gel used in electrophoresis Urea-formaldehyde resin Urea and formaldehyde $-[NH-CO-NH-CH_2]-_n$ Unbreakable dinnerware, decorative laminates Glyptal Ethylene glycol and phthalic acid Ester linkage with cyclic structure Paints and lacquers Polycarbonate Bisphenol A and phosgene Carbonate linkage with aromatic rings Electrical/telecommunication hardware, food grade plastic containers Thermocol (Polystyrene) Styrene $-[CH_2-CH(C_6H_5)]-_n$ Non-biodegradable, can leach when heated (banned for some uses)