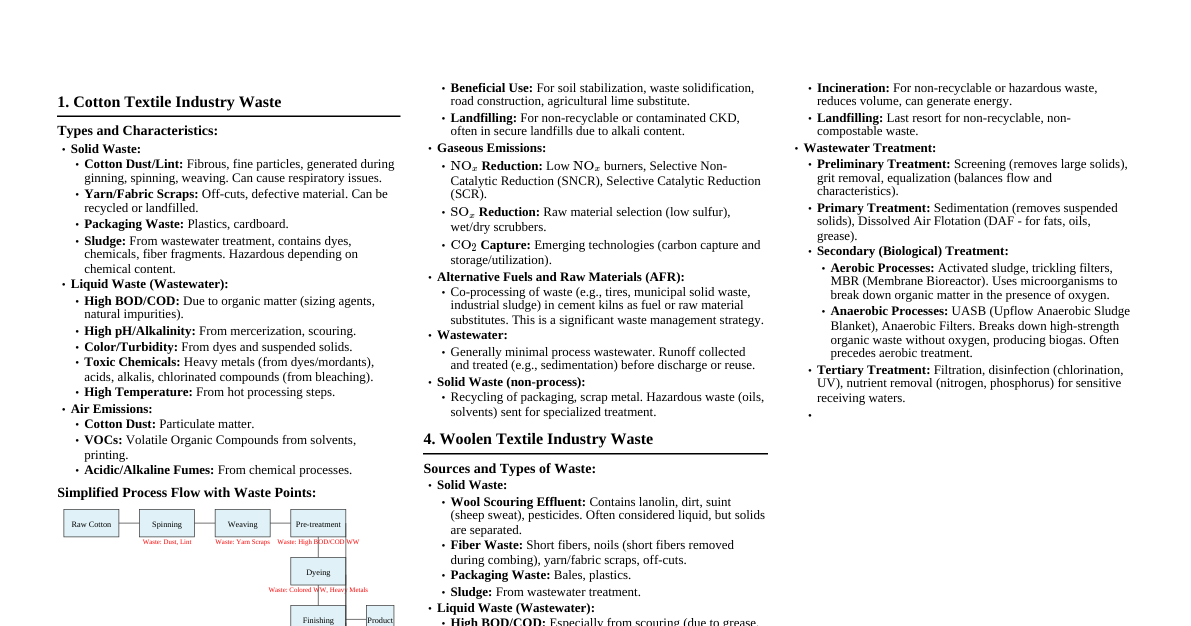

### Boiler Types: Water Tube vs. Fire Tube - **Water Tube Boiler:** - Water flows inside tubes, hot gases flow outside. - Higher pressure and capacity. - Faster steam generation. - Used in power plants and large industries. - Example: Babcock & Wilcox boiler. - **Fire Tube Boiler:** - Hot gases flow inside tubes, water flows outside. - Lower pressure and capacity. - Slower steam generation, larger water volume. - Used in smaller industrial applications, locomotives. - Example: Scotch marine boiler. ### Two-Element Boiler Feedwater Control - **Purpose:** To maintain a stable water level in the boiler drum. - **Components:** 1. **Water Level Transmitter:** Measures drum water level. 2. **Steam Flow Transmitter:** Measures steam flow rate (load demand). 3. **Controller:** Compares actual level to setpoint, and steam flow to feedwater flow. - **Working Principle:** - Primarily controls feedwater flow based on drum level deviation. - Secondary control signal from steam flow (load) provides feedforward action. - **Advantage:** Compensates for 'shrink' and 'swell' effects by anticipating feedwater demand based on steam load, leading to more stable control than single-element. - **Mechanism:** If steam demand increases, steam flow signal immediately increases feedwater, preventing level drop due to shrink before the level transmitter registers it. ### Heat Exchanger: Feedback & Bypass Controls - **Feedback Control:** - **Objective:** Maintain desired outlet temperature of the process fluid. - **Mechanism:** A temperature sensor measures the outlet temperature. This signal is sent to a controller, which compares it to a setpoint. The controller then adjusts the flow of the heating/cooling medium (e.g., steam, cooling water) through a control valve. - **Example:** If outlet temperature is too high, the controller reduces steam flow to the heat exchanger. - **Bypass Control:** - **Objective:** Provide fine-tuning or quick response, often used in conjunction with feedback. - **Mechanism:** A portion of the process fluid (or heating/cooling medium) is diverted around the heat exchanger via a bypass line with a control valve. - **Example:** To reduce the outlet temperature of the process fluid, some of the cold inlet fluid is bypassed directly to the outlet, blending with the heated fluid. This can provide faster response than adjusting the main heating/cooling medium flow. ### Boiler Drum Level Control: Shrink & Swell Effects - **Why Control Level?** - **Too Low:** Overheating of boiler tubes, potential for explosion. - **Too High:** Carryover of water into steam lines, damaging turbines and other equipment, reduced steam quality. - **Shrink Effect:** - **Cause:** Sudden increase in steam demand (load). - **Mechanism:** Pressure in the drum drops. This causes some water to flash into steam, increasing the volume of steam bubbles in the water. The increased steam volume displaces water, leading to a *temporary drop* in the indicated water level, even though the total mass of water has not significantly changed. - **Control Challenge:** A control system reacting only to level would incorrectly increase feedwater flow. - **Swell Effect:** - **Cause:** Sudden decrease in steam demand (load). - **Mechanism:** Pressure in the drum rises. This causes some steam bubbles to collapse back into water, decreasing the volume of steam bubbles. The decreased steam volume allows the water level to *temporarily rise*, even though the total mass of water has not significantly changed. - **Control Challenge:** A control system reacting only to level would incorrectly decrease feedwater flow. ### Boiler: Swelling and Shrinking Effect - **Boiler Definition:** A closed vessel in which water is heated, steam is generated, superheated, or any combination thereof, under pressure or vacuum by the direct or indirect application of heat. - **Swelling Effect:** - Occurs when boiler load **decreases** (steam demand falls). - Drum pressure **increases**. - Steam bubbles in the water collapse due to higher pressure. - The overall volume occupied by the water/steam mixture **decreases**, leading to a *temporary rise* in the indicated water level. - **Shrinking Effect:** - Occurs when boiler load **increases** (steam demand rises). - Drum pressure **decreases**. - More water flashes into steam, increasing the volume of steam bubbles. - The overall volume occupied by the water/steam mixture **increases**, leading to a *temporary drop* in the indicated water level. - **Impact on Control:** These effects make single-element drum level control difficult as the indicated level does not accurately reflect the actual water inventory during load changes. Multi-element controls (e.g., two-element or three-element) are used to compensate. ### Feedback Control Scheme for Double Effect Evaporator - **Objective:** Maintain desired concentration of the product from the second effect and/or maintain a stable level in both effects. - **Typical Control Loops:** 1. **Product Concentration Control:** - **Measured Variable:** Concentration of product from the second effect (e.g., via densitometer/refractometer). - **Manipulated Variable:** Steam flow to the first effect. - **Mechanism:** If product concentration is too low, more steam is supplied to the first effect to increase evaporation. 2. **Level Control (Effect 1 & 2):** - **Measured Variable:** Liquid level in each effect. - **Manipulated Variable:** Outlet flow from each effect (e.g., transfer flow from effect 1 to effect 2, and product flow from effect 2). - **Mechanism:** If level is too high, outlet flow is increased. 3. **Feed Flow Control:** Often used as a feedforward control or cascaded with concentration control. - **Feedback Loop Example for Concentration:** - A controller receives the concentration measurement from the second effect. - It compares this to the setpoint. - Based on the error, it adjusts the control valve on the steam supply to the first effect. - This ensures the final product meets specifications. ### Compare Unit Operations and Unit Processes - **Unit Operations:** - **Definition:** Physical changes or transformations undergone by materials. These are common physical steps in many different chemical processes. - **Focus:** Physical phenomena (mass transfer, heat transfer, fluid mechanics, etc.). - **Examples:** Distillation, absorption, extraction, filtration, drying, evaporation, mixing, crushing, crystallization. - **Independence:** Can be studied and designed independently of the specific chemical reaction involved. - **Unit Processes:** - **Definition:** Chemical changes or transformations where raw materials are converted into products through chemical reactions. - **Focus:** Chemical reactions and associated reactor design. - **Examples:** Oxidation, nitration, hydrogenation, polymerization, esterification, combustion. - **Dependence:** The design and conditions are highly dependent on the specific chemical reaction taking place. - **Relationship:** A complete chemical process typically involves a sequence of both unit processes (for chemical transformation) and unit operations (for physical separation, purification, and preparation). ### Selective Control for Evaporator - **Objective:** To manage multiple control objectives (e.g., level, concentration, temperature) for an evaporator, especially during abnormal conditions or to optimize performance. - **Mechanism:** A selective control system uses multiple measurements and a logic unit to determine which control loop should be active at any given time, or which control signal should be sent to a final control element. - **High-Select Control (Override Control):** - **Example:** In an evaporator, a control valve might be used to regulate feed flow to maintain level. However, if the concentration in the evaporator gets too high (e.g., approaching solubility limits), a high-select controller could override the level controller to increase feed flow, preventing fouling, even if it temporarily upsets the level. - **Working:** Two (or more) controllers have outputs connected to a high-selector or low-selector. The selector passes through the signal that meets the criteria (e.g., the highest signal to open a valve, or the lowest signal to close it). - **Application in Evaporator:** Could be used to prevent foaming, excessive concentration, or maintain minimum operating level, by allowing one controller to take command when its variable approaches a critical limit, overriding the primary controller. ### Furnace Control with Interlock - **Furnace Control Objective:** Maintain desired temperature, safe operation, and efficient combustion. - **Key Control Loops:** 1. **Temperature Control:** Measures furnace temperature and adjusts fuel flow rate to the burners. 2. **Fuel/Air Ratio Control:** Maintains the optimal ratio of fuel to combustion air for efficient burning and to minimize emissions (e.g., CO). 3. **Draft Control:** Regulates furnace pressure by adjusting flue gas damper position, ensuring proper exhaust and preventing flame impingement. - **Interlocks (Safety System):** - **Definition:** Logic circuits or mechanical devices that prevent an operation from occurring unless certain preconditions are met, or trigger a shutdown if unsafe conditions arise. They ensure safe startup, operation, and shutdown. - **Purpose:** Prevent explosions, equipment damage, and personnel injury. - **Examples of Furnace Interlocks:** - **Pre-Purge:** Furnace must be purged with air for a set time before ignition to remove any accumulated fuel vapors. - **Flame Failure:** If a flame detector fails to sense a flame after ignition, or if the flame extinguishes during operation, the fuel supply is immediately shut off. - **Low Fuel Pressure:** Prevents ignition or shuts down if fuel pressure is too low to maintain stable flame. - **High Fuel Pressure:** Shuts down if fuel pressure is too high, indicating a potential leak or oversupply. - **Low Air Flow/Pressure:** Ensures sufficient combustion air before and during operation; shuts down if air supply is inadequate. - **High Furnace Temperature:** Shuts down or reduces fuel if temperature exceeds safe limits. - **Emergency Stop (ESD):** Manual button to immediately shut down all fuel and air. ### Classify Heat Exchangers Based on Fluid Flow Arrangement - **Heat Exchanger Definition:** A device used to transfer heat between two or more fluids at different temperatures. - **Classification by Flow Arrangement:** 1. **Parallel Flow (Co-current Flow):** - **Arrangement:** Both hot and cold fluids flow in the same direction through the heat exchanger. - **Temperature Profile:** Both fluid temperatures approach each other, but the cold fluid never reaches the inlet temperature of the hot fluid. - **Effectiveness:** Less effective than counter-flow for achieving large temperature changes. 2. **Counter-Flow (Counter-current Flow):** - **Arrangement:** Hot and cold fluids flow in opposite directions. - **Temperature Profile:** Allows for the maximum possible heat transfer and for the cold fluid to exit at a temperature higher than the hot fluid's outlet temperature. - **Effectiveness:** Most effective arrangement for heat transfer. 3. **Cross-Flow:** - **Arrangement:** Fluids flow perpendicular to each other. One fluid might be unmixed (e.g., in separate tubes) while the other is mixed (e.g., flowing over the tubes). - **Temperature Profile:** Intermediate effectiveness between parallel and counter-flow. - **Examples:** Car radiators, air conditioning coils. 4. **Shell and Tube Heat Exchangers (Mixed Flow):** - Often combine elements of cross-flow and counter-flow. - One fluid flows through a bundle of tubes (tube side), and the other fluid flows outside the tubes, within a shell (shell side). Baffles direct the shell-side fluid, creating a complex flow path. ### Types of Boilers & Single Element Drum Level Control - **Types of Boilers (Reiteration & Expansion):** 1. **Fire Tube Boilers:** Hot gases inside tubes, water outside. (e.g., Scotch, Locomotive, Vertical, Cornish, Lancashire). 2. **Water Tube Boilers:** Water inside tubes, hot gases outside. (e.g., Babcock & Wilcox, Sterling, La-Mont, Benson). 3. **High Pressure Boilers:** Operate at very high pressures (e.g., Benson, Loeffler, Velox). 4. **Low Pressure Boilers:** Operate at lower pressures (e.g., domestic heating boilers). 5. **Packaged Boilers:** Factory-assembled units, compact, high efficiency. 6. **Fluidized Bed Boilers (FBC):** Burn fuel in a bed of inert material suspended by air, efficient for various fuels. 7. **Waste Heat Boilers (WHB):** Recover heat from hot gas streams. - **Single Element Drum Level Control:** - **Mechanism:** A single feedback loop that measures the boiler drum water level and adjusts the feedwater flow to maintain that level. - **Components:** Level transmitter, controller, control valve on feedwater line. - **Working:** If the level is below the setpoint, the controller opens the feedwater valve more. If the level is above the setpoint, it closes the valve. - **Limitations:** Highly susceptible to 'shrink' and 'swell' effects during load changes. A sudden increase in steam demand (shrink) causes the indicated level to drop, leading the controller to wrongly increase feedwater, potentially causing a high level when the effect passes. Conversely, a sudden drop in demand (swell) causes the indicated level to rise, leading to a reduction in feedwater, potentially causing a low level. - **Application:** Suitable only for very small boilers or boilers with extremely stable loads where rapid load changes are not expected.