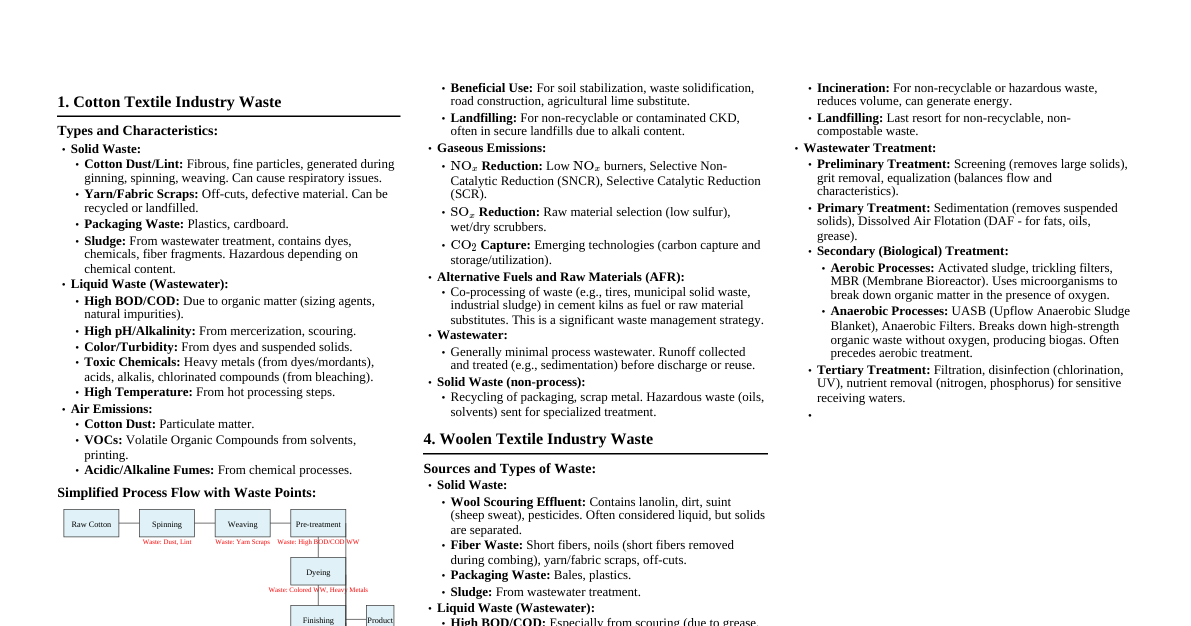

I. Material Handling & Lifting Safety A. Manual Material Handling Hazards Excessive load, improper lifting, unsafe grip/placement. Struck by/against objects, falls/slips, inadequate PPE use. B. Mechanical Lifting Equipment Overhead Travelling Cranes (EOT): Elevated runway, 3-axis hook motion. Safety: Safe access, anti-collision, >2m head clearance, rubber mat at panel, park with hook raised. Jib Cranes: Stationary/mobile, horizontal/inclined jib, circular arc lift. Safety: Clear SWL (Safe Working Load) marking, end stops (bumpers). Bridge & Gantry Cranes: Bridge (elevated rails), Gantry (ground rails). Safety: Over-travel limits, bare conductor protection, inadvertent operation prevention, load indicators (audio-visual), sounding device when moving. C. General Crane & Lifting Safety SWL: Never exceed marked Safe Working Load. Operation: Only trained/authorized personnel. Maintenance: Regular inspection, cleaning, lubrication. Load Path: Never over heads. Access: Safe and adequate for overhead cranes. Statutory (Factories Act, India): Lifting machines, chains, ropes, tackles must be strong, good material, maintained, and examined by a competent person (6 months for hoists/lifts, annually for others). II. Major Hazard Management A. Defining Major Hazards & Accidents Major Hazard: Potential for widespread death, injury, property/environmental damage (e.g., flammable/toxic releases). Major Accident (MSIHC Rules, India): Defined by loss of life, multiple injuries, significant chemical release, equipment damage, environmental effects. B. Specific Major Hazards Flammable Material Release: Fire, Explosion, BLEVE (Boiling Liquid Expanding Vapor Explosion - vessel failure, rapid phase change, fireball). Toxic Gas Release: Serious health effects over distance (acute focus). C. Major Hazard Control Plan Identify hazardous installations (MAH). Assess & Limit Risk (HAZOP, FTA, ETA, Vulnerability Assessment). Prepare Emergency Plans (On-site & Off-site). D. Risk Assessment & Vulnerability Risk: Probability $\times$ Consequence. Vulnerability Assessment: Studies accident consequences on population/property in vulnerable zone (population data, property data, modeling for fatalities/injuries/damage). Toxic Dose: $C^N \cdot t$. E. Emergency Response Planning Guidelines (ERPG - AIHA) ERPG-3: Max 1hr airborne conc. without life-threatening effects. ERPG-2: Max 1hr airborne conc. without serious/irreversible effects or impaired protective action. ERPG-1: Max 1hr airborne conc. without mild/transient effects or objectionable odor. F. Emergency Plan Development Steps Accident potential evaluation. Management support & organization. Facilities & equipment. Action procedures. Training. Coordination with external agencies. Public relations. Legal assistance. Termination & restoration. Testing & critiquing. III. Hazard Identification, Assessment & Control A. Hazard vs. Risk Hazard: Potential for harm. Risk: Probability of harm $\times$ Severity of harm. B. Risk Analysis Steps Hazard Identification $\to$ Consequence Assessment $\to$ Accident Frequency Assessment $\to$ Risk Estimation. C. Hazard Identification & Assessment Techniques Check-lists: Quick, qualitative. PHA (Preliminary Hazard Analysis): Early design phase. Safety Review/Audit: In-depth examination of operating system. Relative Ranking (Dow/Mond Indices): Quantitative hazard ranking. "What If" Analysis: Deviations from intent. HAZOP (Hazard and Operability Study): Systematic, team-based, uses guidewords (NO, MORE OF, etc.) on process parameters to identify deviations and consequences. FMECA (Failure Modes, Effects and Criticality Analysis): Component-level failure analysis. Fault Tree Analysis (FTA): Deductive ("effect to cause"), identifies basic failures leading to a top event (AND/OR gates, minimal cut sets). Event Tree Analysis (ETA): Inductive ("cause to effect"), evaluates outcomes from initiating event through safety functions. IV. Personal Protective Equipment (PPE) A. Hierarchy of Controls (Most to Least Effective) Eliminate/Substitute. Engineering Controls. Administrative Controls. PPE (last line of defense). B. Respiratory Protection Hazards: Toxic gases/vapors/dusts, O$_2$ deficiency. Types: Air-Purifying (filters/cartridges): For particulates or specific gases/vapors (not O$_2$ deficient/IDLH). Atmosphere-Supplying (airline/SCBA): For O$_2$ deficiency, IDLH, or unknown concentrations. SCBA: Self-Contained Breathing Apparatus (Open/Closed circuit). Selection: Based on contaminant, concentration, O$_2$ level. APF (Assigned Protection Factor): Respirator's protection level (e.g., APF 10 means $1/10$th exposure). ESLI (End of Service Life Indicator): Cartridge replacement signal. MUC (Maximum Use Concentration): OEL $\times$ APF (must be $\le$ IDLH). Compressed Air (IS 15879): Limits for CO (15ppm), CO$_2$ (500ppm), particulates (0.5mg/m$^3$). C. Non-Respiratory PPE Head: Safety helmets (shell, suspension, $\ge 30$mm clearance). Eye/Face: Goggles (chemical, gas-tight, welding), Face shields (for impact/splash). Ear: Earmuffs, Earplugs. NRR (Noise Reduction Rating). Hand: Gloves (metal mesh, rubber, neoprene, leather, cotton) for cuts, chemicals, heat. NEVER near rotating machinery. Foot: Safety shoes (steel-toed, electrical, chemical-resistant, slip-resistant). Fall: Safety belt/harness (part of fall arrest system, periodic inspection). Body: Protective clothing (flame, chemical, high-vis). Welding: Helmet with appropriate Shade Number. V. Industrial Hygiene: Physical Agents A. Noise Effects: Auditory (TTS, NIHL, Tinnitus), Non-auditory (stress, fatigue). Measurement: dB scale ($20 \log_{10} [P/Pref]$), A-weighting for continuous noise. Control: Engineering (enclosure, absorption, maintenance), Administrative (rotation, reduced duration), PPE (earplugs/muffs). OEL (AEFR 1996): No exposure $\ge 115$dBA, or $\ge 140$dB Peak. B. Vibration HTV (Hand-Transmitted): VWF (Vibration-Induced White Finger), musculoskeletal issues. WBV (Whole-Body): Back pain, digestive issues, fatigue. OEL (ACGIH): HTV TLV 5m/s$^2$, WBV TLV 0.87m/s$^2$. Control: Ergonomic design, limited duration, maintenance, anti-vibration PPE. C. Non-Ionizing Radiation UV: UV-A, UV-B, UV-C. Acute (arc-eye, keratitis), Chronic (skin cancer, cataracts). IR: IR-A, IR-B, IR-C. Acute (retinal burn), Chronic (cataracts). LASER: Eye damage, skin burns, electrical hazard. Classes 1-4 (increasing hazard). Protection: Goggles with suitable OD (Optical Density), MPE (Max Permissible Exposure). RF/Microwave: Heating effects (SAR), CNS interference. D. Thermal Stress (Heat) Effects: Heat exhaustion, cramps, stroke, reduced productivity. Indices: WBGT (Wet-Bulb Globe Temperature) considers temp, humidity, radiant heat, air movement. Prevention: Hydration, cool breaks, acclimatization, appropriate clothing. E. Electrical Hazards Primary: Shock (fibrillation, tetanus), Burn, Fire/Explosion (arc flash/blast). Severity: Current magnitude, duration, path, AC/DC. Let-go current. Control: Insulation, Guarding, Grounding, Protective Devices (fuses, MCB, RCD/ELCB), Safe work practices (LOTO). F. Fire & Explosion Hazards Fire Triangle: Fuel, Oxygen, Heat. Fire Tetrahedron adds Chain Reaction. Flash Point: Min temp for ignitable vapor. Auto-Ignition Temp: Spontaneous ignition. Flammability Limits: LFL/LEL (too lean), UFL/UEL (too rich). Fire Load: Heat liberated per unit area. FRR (Fire Resistance Rating): Time a material withstands fire. Extinction: Cooling, Smothering, Starvation, Breaking chain reaction. Classes (IS:2190): A (solids), B (liquids), C (gases), D (metals). Appliances: Active (hydrants, extinguishers, sprinklers), Passive (barriers, retardants). G. Cryogenic Hazards Extremely low temps ($ Hazards: Freezing (frostbite), Hypothermia, Asphyxiation (O$_2$ displacement), Cold embrittlement, Over-pressurization. LOX: Strong oxidizer, supports vigorous combustion. Safety: Ventilation, PPE, O$_2$ monitoring, avoid condensation. VI. Machine Safety A. Machine Hazards Struck by, entanglement, electrical, chemical, noise, vibration. Motions: Rotating, Reciprocating, Transverse. Danger Points: Point of operation, power transmission, other moving parts. B. Safeguarding Requirements: Prevent contact, secure, no new hazards, no interference. Methods: Guards: Fixed, Distance, Interlock (machine stops if opened), Adjustable, Self-adjusting. Devices: Presence-sensing (photoelectric, mats), Two-hand control, Pullbacks/Restraints, Safety trip controls. Other: LOTO (Lock Out/Tag Out), E-stops. Control Hierarchy: Eliminate $\to$ Substitute $\to$ Engineering (guards) $\to$ Administrative (procedures) $\to$ PPE. C. Training & Procedures Training: Equipment-specific, PPE, LOTO, emergency. SOPs (Safe Operating Procedures), maintenance schedules. VII. Chemical Hazards & Handling A. Chemical Hazard Categories Physical: Flammable (liquids, solids, gases), Explosive, Gases under pressure, Oxidizing, Water-reactive, Pyrophoric, Peroxide-forming. Health: Toxic, Corrosive, Irritant, Sensitizer, Carcinogen, Mutagen, Teratogen. B. Health Hazard Details Physical Form: Solids, Aerosols, Liquids, Vapors. Routes of Exposure: Inhalation (most common), Ingestion, Skin contact/absorption. Target Organs: Lungs, Liver, Kidneys, CNS, etc. Exposure: Acute (single, high dose), Chronic (repeated, low dose). Effects: Local (contact site), Systemic (body-wide), Latent (delayed). Toxicity: LD$_{50}$ (Lethal Dose), LC$_{50}$ (Lethal Concentration), IDLH. Interaction: Synergism (combined > sum), Antagonism (combined Classes: Irritants, Asphyxiants (simple/chemical), Anaesthetics/Narcotics, Systemic Poisons, Pneumoconiosis agents, Carcinogens (ACGIH A1-A5). C. Chemical Handling & Control General: Know properties (SDS), store minimum, separate incompatibles, proper containers/labels, PPE (fume hood, gloves, goggles), spill control, no food/drink/smoking. Fume Hoods: Exhaust hazardous fumes, $\ge 0.5$m/s face velocity, not for storage. Ventilation: Dilution (3-6 ACH), LEV (Local Exhaust Ventilation). Keep concentrations Monitoring: Instrumental (direct reading), Air Sampling, Biological Monitoring. D. Chemical Waste Disposal Hierarchy: Minimize $\to$ Reduce/Reuse/Recover $\to$ Treat $\to$ Dispose. Methods: Dilute & Disperse (limited), Incineration, Solidification (cement), Landfill, Vitrification. Prohibited to Drain: Flammable, high/low pH, viscous, radioactive, strong odor, high temp, pharmaceuticals. Unlabeled Chemicals: Treat as highly hazardous, identify, screen for reactivity, especially peroxide formers. VIII. Safety Management & Regulations A. Industrial Safety Management Manages activities to reduce risks, prevent injury/illness, foster safety culture. Hygiene vs. Safety: Hygiene (health stressors, long-term), Safety (acute injury, immediate hazards). Heinrich's Domino Theory: Chain of five factors leading to accident (Social $\to$ Fault $\to$ Unsafe Act/Condition $\to$ Accident $\to$ Injury). Remove a factor to break chain. Factories Act (India): Regulates working conditions, health, safety, welfare. B. Accidents & Costs Unplanned, undesired events. Outcomes: Injury, death, property damage, lost productivity, litigation. Costs: Direct (medical, compensation), Indirect (3-4x direct: lost time, investigation, morale). Causes: Basic (management policy, personal/job factors) $\to$ Indirect (unsafe acts/conditions) $\to$ Accident. C. Accident Prevention & Control Program: Recording IOD (Injury on Duty), investigating accidents/near-misses, analysis (IS 3786). Metrics: Frequency Rate (FR), Severity Rate (SR), Injury Index. Measures: Eliminate unsafe acts/conditions, facility inspections, safety committee, safe work practices/SOPs, training, recordkeeping, program evaluation. D. Information & Communication SDS (Safety Data Sheet - 16 sections): Comprehensive chemical info. NFPA 704 (Diamond): Health (blue), Flammability (red), Reactivity (yellow), Special (white) - rated 0-4. UN Code (Dangerous Goods): 9 classes for transport. Labels/Signs: Clear warnings, contents, hazards, PPE, first aid. Employee Info: Hazards, detection, PPE, SDS access.