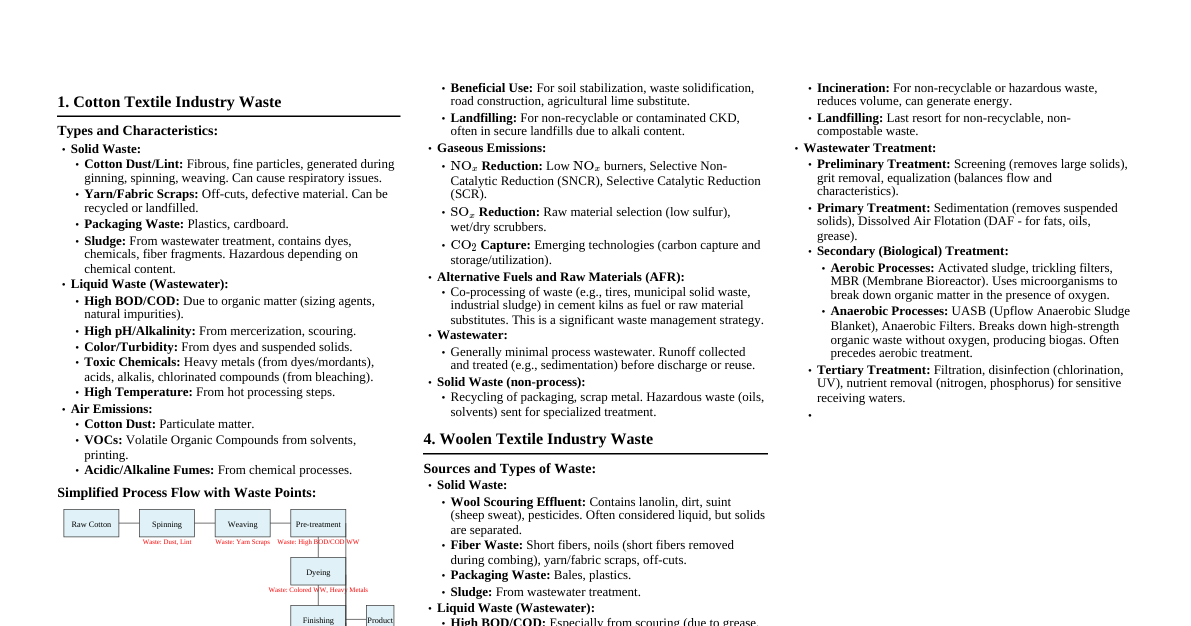

1. Material Handling 1.1 Hazards of Manual Material Handling Carrying excessive load. Lifting improperly. Unsafe gripping or placing. Struck by falling body or striking against object. Person falling or slipping. Failure to wear PPE. 1.2 Ways of Material Handling Manual Handling Mechanical Handling 2. Types and Safety Aspects of Lifting Machines 2.1 Overhead Travelling Cranes (EOT Cranes) Run on an elevated runway system. Provide three axes of hook motion. Allow precise positioning and gentle load placement. Safety Measures: Safe and adequate means of access (ladders, steps, stairways). Effective means to prevent crane from travelling into dangerous zones. Vertical head clearance between walkway and overhead structure $> 2$ m. Rubber mat at control panel for electric shock protection. Park with hook raised, all controls off when not in use. 2.2 Jib Cranes Stationary or mobile crane with a projecting, horizontal or inclined jib. Lifts, lowers, and rotates load within a circular arc. Safety Measures: Capacity and maximum safe working load (SWL) for various jib inclinations/positions must be clearly marked. Stop plate (bumper) at jib end to prevent load trolley from running off beam; frequent checks required. 2.3 Bridge and Gantry Cranes Similar to travelling cranes but run on ground-level rails. Gantry cranes have short spans; bridge cranes can have spans up to 100 m or more. Safety Measures: Design safety measures: over-travel limit switches, bare conductor protection, controls to prevent inadvertent operation, load indicators (audio-visual automatic excess load indicator), SWL marking. A sounding device should warn when the crane is moving. 3. Basics of Crane Safety Safe Working Load (SWL): Limiting safety factor for lifting/carrying loads safely; must be clearly marked. Only trained and authorized persons should operate a crane. Cranes should be regularly examined for defects, cleaned, and well lubricated. Load should not be moved over anyone's head. Safe and adequate means of access should be provided for overhead cranes. 3.1 Safety Requirements (Factories Act, Sections 28 & 29) All hoists, lifts, lifting machines, chains, ropes, and lifting tackles must be of good construction, sound material, and adequate strength. Properly maintained and thoroughly examined by a competent person at least once every 6 months for hoists and lifts. 4. Management of Major Hazards 4.1 Major Hazards Definition Potential to cause death, injuries to many persons, and/or extensive damage to property or environment. e.g., Release of Flammable Material (Fire & Explosion), Release of Toxic Gases/Chemicals. 4.2 Major Accident Definition (MSIHC Rules, 1989) Loss of life inside or outside the installation. 10 or more injuries inside and/or 1 or more injuries outside. Release of toxic chemicals, explosion, fire, or spillage of hazardous chemicals resulting in on-site or off-site emergencies. Damage to equipment leading to process stoppage. Adverse effects to the environment. 4.3 Leakage of Flammable Material Fire Explosion BLEVE (Boiling Liquid Expanding Vapour Explosion): Combination of fire and explosion when a pressure-vessel with liquefied gas above its atmospheric boiling point fails. Instantaneous release forms a turbulent mixture of liquid and gas, expanding rapidly. Ignition creates a fireball and intense thermal radiation. 4.4 Release of Toxic Gases Serious health effects over great distances depending on quantity, wind direction, and velocity. Major hazard control primarily considers acute effects rather than chronic effects. 4.5 Major Hazard Control Plan Components Identification of hazardous installations. Assessment of risk and limiting the risk. Preparation of emergency plans (on-site and off-site). 4.6 Identification of Major Hazard Installations (MAH) Isolated storage and industrial activity handling hazardous chemicals (including transport) equal to or exceeding threshold quantities. Threshold quantities are specified in the MSIHC Rules, 1989. 4.7 Risk Assessment Risk is quantified as: $Risk_{consequences/yr} = Frequency_{events/yr} \times Magnitude_{consequences/event}$. Methods: HAZOP, Fault Tree Analysis, Event Tree Analysis, Vulnerability Assessment. 4.8 Vulnerability Assessment Studies accident consequences on population in the vulnerable zone (area affected by leakage/spillage). Collects population data (number, density, special groups like hospitals, schools) and property data. Uses standard models to predict fatalities/injuries and property damage based on propagation of chemical/thermal radiation. Considers environmental damages (forestry, water bodies). 4.9 Predicting Consequences of Toxic Dispersion Toxic Dose is often modeled as $Toxic Dose = C^N \cdot t$ (where $C$ is concentration, $t$ is time, $N$ is a constant). 4.10 Emergency Response Planning Guidelines (ERPG) - AIHA ERPG-3: Max airborne concentration for 1 hour without life-threatening health effects. ERPG-2: Max airborne concentration for 1 hour without irreversible/serious health effects or symptoms impairing protective action. ERPG-1: Max airborne concentration for 1 hour without mild, transient adverse health effects or objectionable odor. Sensitive individuals (old, sick, very young) are not covered. 4.11 Emergency Planning Guidelines for Toxic Gas Release Three Classes of Emergency (based on potential exposure): Incidents, On-Site (Level One), Off-Site (Level Two). Decided using TLV (Occupational Exposure Limit) and Level of Concern (LOC = 1/10th of IDLH). Incident: Air concentration $<$ TLV. On-Site (Level One): TLV $<$ air concentration $<$ LOC. Off-Site (Level Two): Air concentration $>$ LOC. 4.12 Emergency Plan Development Evaluation of accident potential Management support Emergency organization Emergency facilities and equipment Action procedures Emergency training and retraining Coordination with outside agencies Public relations Legal assistance Termination of emergency and Restoration of normalcy Testing and critiquing the plan 5. Hazard Identification, Assessment and Control 5.1 Hazard & Risk Definitions Hazard: A physical situation with potential for an accident (injury, property damage, environmental damage). Risk: Probability of a given undesirable event with specific consequences in a specified time period. $Risk_{consequences/yr} = Frequency_{events/yr} \times Magnitude_{consequences/event}$. Risk Analysis: Hazard Identification, Consequence Assessment, Accident Frequency Assessment, Risk Estimation. 5.2 Hierarchy of Controls Eliminate or Substitute (1st Preference) Engineering Controls Administrative Controls Personal Protective Equipment (PPE) 5.3 Hazard Identification & Assessment Techniques Check-lists Safety Review/Safety Audit Preliminary Hazard Analysis (PHA) Relative ranking - Dow and Mond Indices "What If" Analysis Hazard and Operability (HAZOP) Studies Failure Modes, Effects and Criticality Analysis (FMECA) Fault Tree Analysis (FTA) Event Tree Analysis (ETA) Cause-Consequence Analysis 5.4 Check-lists Purpose: Quick identification of hazards. Applicable in all plant lifecycle stages. Limitations: Qualitative, quality depends on author's knowledge/experience. 5.5 Preliminary Hazard Analysis (PHA) Purpose: Early identification of hazards during design phase. Cost-effective for early design changes. 5.6 Safety Review/Safety Audit Purpose: Ensure procedure matches design intent. Methodical in-depth examination of operating system for safety. Components: Audit Team, Pre-audit Questionnaire/Interviews, Plant Visit, Document Verification, Meeting with management, Safety audit report. 5.7 Relative Ranking Method Assigns penalties for hazardous process materials/conditions and credits for safety features. Combines these to derive an index for relative plant risk ranking (e.g., Dow Index, Mond Index). Qualitative method. 5.8 "What If" Analysis Examines deviations from design/operation intent (e.g., "What if the wrong material is delivered?"). Effective with experienced staff; results may be incomplete otherwise. Common for proposed plant changes. 5.9 Hazard and Operability (HAZOP) Studies Fundamental, qualitative hazard identification technique. Examines each major hardware item ("study node") for causes/consequences of deviations from normal operating conditions using "Guide Words" and "Parameters". Guide Words: NO, MORE OF, LESS OF, AS WELL AS, PART OF, REVERSE, OTHER THAN. Teamwork approach with diverse expertise. Assumptions: Plant operates as intended without deviations; operators are trained (human error not considered). Timing: Conducted when design is almost finalized but equipment/control not firmed up, or for plant modifications. HAZOP Team: Instrument, Project, Design, Maintenance, Operations, Safety Engineer, Plant Foreman. Example: HAZOP table for "NO COOLING" deviation, listing causes, consequences, and actions. 5.10 Fault Tree Analysis (FTA) Hazard analysis technique focusing on a "Top Event" (accident). Backward thinking ("Effect to Cause") using logical gates (AND, OR) to connect Top Event to intermediate events and basic/primary events (Faults). Faults Categories: Primary (within design limit), Secondary (beyond design limit), Command (operates properly but at wrong time). Qualitative with quantitative potential; includes human errors and equipment failures. Steps: Define TOP EVENT, Fault Tree Construction, Fault Tree Solution (Minimal Cut Sets). Minimal Cut Sets: Smallest combinations of failures sufficient to cause the accident. 5.11 Event Tree Analysis (ETA) Hazard analysis technique focusing on an "Initiating Event" (equipment failure or human error). Forward thinking ("Cause to Effect") evaluating potential outcomes based on success/failure of safety functions. Qualitative with quantitative potential; includes human errors and equipment failures. Steps: Identify initiating event, identify safety functions, construct event tree, describe accident sequences. Example: ETA for "Loss of cooling water to reactor", showing safety functions (alarm, operator action, shutdown) and resulting probabilities for shutdown or runaway. 6. Personal Protective Equipment (PPE) 6.1 Types of PPEs Non-Respiratory: Head, Face & Eyes, Ear, Hand, Foot. Respiratory: Protection against inhalation hazards. 6.2 Respiratory Protection - Hazards Toxic Gases/Vapors/Fumes Dust Oxygen deficiency 6.3 Routes of Entry for Contaminants Inhalation Skin Absorption Ingestion 6.4 Situations Needing Respirators Oxygen Deficiency Presence of Gaseous Contaminants Presence of Air-borne Particulate Matter Any combination of the above 6.5 Types of Respirators Dust Respirators Vapours and Gases Respirators (Air Purifying: Dust Filters, Cartridge Respirators) Fresh Air Line Respirators (Air Supplying) Self-Contained Breathing Apparatus (SCBA) (Air Supplying) 6.6 Particulate Filters Air purifying half mask respirator with filters to trap harmful particles. Useful for dust, mists, smoke. 6.7 Chemical Filters Sorbent chemical filtering devices remove gaseous and vapor contaminants. Not suitable for airborne particles. 6.8 Fresh Air Line Respirator Supplies air from compressed air line. Protects against dust, toxic fumes, and oxygen deficiency. Limitation: Air hose can be a nuisance, reduce worker efficiency. 6.9 Self-Contained Breathing Apparatus (SCBA) Enables wearer to breathe independently of surrounding atmosphere using an integral supply of air or oxygen. Types: Open circuit: Exhaled air passes to atmosphere. Closed circuit: Exhaled air purified and re-circulated with added oxygen. 6.10 Precautions in SCBA Use Person must be physically sound and fit. Equipment in good condition. Person requires training. Ensure adequate air supply. Return to fresh air if any irritation occurs. Be aware of time limitations. 6.11 Selection of Respirators Environment/Purpose Respirator Particulates Dust Filter Gases & Vapours (Conc. Below IDLH) Cartridge or Canister Respirator, Fresh Airline Gases & Vapours (Conc. Above IDLH) SCBA, Fresh Airline Oxygen Deficient Atmosphere SCBA Fire Fighting SCBA 6.12 Assigned Protection Factor (APF) Reflects the level of protection a properly functioning, fitted, and used respirator provides. e.g., APF of 10 means user inhales no more than one-tenth of airborne contaminant. 6.13 End of Service Life Indicator (ESLI) for a Cartridge Respirator Helps determine when the cartridge can no longer effectively filter contaminants. Provides a visual or audible signal for replacement. If no ESLI, rely on time-based replacement schedules or monitoring. 6.14 Maximum Use Concentration (MUC) of a Cartridge Respirator Highest concentration of a contaminant the respirator can effectively protect against. $MUC = APF \times OEL$. 6.15 Noise Reduction Rating (NRR) Quantifies effectiveness of hearing protection (earplugs, earmuffs) in reducing noise exposure. Expressed in dB. Higher NRR means greater noise reduction. Actual reduction may be lower due to real-world conditions and fit. 6.16 Shade Number of Welding Helmet Darkness of the lens protecting against intense light and UV/IR radiation from welding arc. Higher shade number (typically 9-14) offers darker lens for more intense welding. 6.17 Contaminants in Compressed Breathing Air (IS 15879) Contaminant Maximum permissible value Carbon Monoxide 15 ppm Carbon Dioxide 500 ppm Particulate Matter 0.5 mg/m$^3$ 6.18 Head Protection (Safety Helmets) Clearance between shell and suspension: not less than 30 mm. Mass: not more than 400 g. 6.19 Eye and Face Protection Hazards: Impact, Chemicals, Dust, Light and/or Radiation. Eye Protectors: Chemical Goggles: Resistant to acid/alkali and toxic chemicals. Gas Tight Goggles: For irritating fumes, vapours, or gases. Welding Goggles: For gas welding/cutting flames and sparks. 6.20 Ear Protection Earmuffs, Earplugs. 6.21 Hand Protection When exposed to: Skin Absorption, Severe Cuts/Lacerations, Abrasions/Punctures, Chemical Burns, Thermal Burns, Temperature Extremes, Radioactive Contamination. Fatal Accident Example: Dimethylmercury penetrating latex gloves in 15 seconds. Glove Material Testing: Breakthrough time, Rate of transfer. Types of Gloves: Metal Mesh, Rubber, Neoprene & Vinyl, Leather, Cotton or Fabric. Caution: Never wear gloves around powered rotating equipment. 6.22 Foot Protection Hazards: Impact, Spills/Splashes, Compression, Electrical Shocks, Extremes in Cold/Heat, Slipping. Types: Steel-toed, Electrical Safety Shoes (metal-free, non-conductive), Chemical Resistant Shoes (rubber). 6.23 Fall Protection (Safety Belt) Purpose: During work at height, protection against fall of person. Periodic examination: Once every six months by a competent person. 6.24 Body Protection (Clothing) Hazards: Temperature stress, Chemical Contact, Radiation. 7. Industrial Hygiene & Safety - Physical Agents 7.1 Industrial Hygiene Definition Science and art devoted to anticipation, recognition, evaluation, and control of workplace environmental factors/stresses that may cause sickness, impair health, or discomfort. Objectives: Prevention of occupational illnesses. 7.2 Hazards due to Physical Agents Noise Vibration Non-Ionizing Radiation (UV, IR, Lasers, MW radiation) Heat Stress 7.3 Occupational Noise Effects on Health: Auditory: Temporary Threshold Shift (TTS), Noise Induced Hearing Loss (NIHL). Non-Auditory: Lack of concentration, Irritation, Fatigue, Headache, Sleep disturbances. 7.4 Measurement of Noise Decibel (dB) Scale: $SPL_{dB} = 20 \log_{10} [P/P_{ref}]$ ($P_{ref}$ = 20 $\mu Pa$). Addition of dB Levels: $L_T = 10 \log_{10}(10^{L_1/10} + 10^{L_2/10} + ... + 10^{L_n/10})$. Equal Loudness Contour: Measure of sound pressure level across frequencies for perceived constant loudness. Frequency Weighting Network: Simulates human ear response (e.g., A-weighting for continuous noise). Factors for Hearing Loss Risk: Sound Intensity, Exposure Duration, Frequency, Individual Susceptibility. 7.5 Control of Noise Engineering Control: Substitution, machine insulation, sound absorption materials, noise-insulated rooms, preventive maintenance, isolation/segregation. Personal/Administrative Control: Job rotation, restriction of exposure duration, ear plugs/ear muffs, education. Medical Control: Audiometric Examination. 7.6 Occupational Exposure Limits (OEL) of Noise (AEFR 1996) No exposure $> 115$ dBA. No exposure $> 140$ dB peak sound pressure level. 7.7 Vibration Hand-Transmitted Vibration (HTV) / Hand-Arm Vibration (HAV): Injury to bones, joints, muscles; arthritis; contractures; Vibration-Induced White Finger (VWF). Whole-Body Vibration (WBV): Musculoskeletal pains (neck, back); cardiovascular disease, digestive problems, motion sickness; discomfort. 7.8 Occupational Exposure Limits (OEL) of Vibration (ACGIH) HTV WBV TLV (8-hr Exposure) $5 \text{ m/s}^2$ $0.87 \text{ m/s}^2$ Action Levels $2.5 \text{ m/s}^2$ $0.43 \text{ m/s}^2$ 7.9 Reduction of Exposure to Vibration Ergonomic design of work equipment. Limitation of duration and intensity of exposure. Regular maintenance. Work schedules with adequate rest. 7.10 Non-Ionizing Radiation Ultraviolet (UV) Radiation: Near UV (UV-A: 400-315 nm), Middle UV (UV-B: 315-280 nm), Far UV (UV-C: 280-100 nm). Health Effects: Skin cancers, Cataracts (chronic); Inflammation of cornea, 'Sand in the eye' sensation ('Arc-eye', 'Welder's Flash') (acute). Infrared (IR) Radiation: Near IR (IR-A: 770-1400 nm), Mid IR (IR-B: 1400-3000 nm), Far IR (IR-C: 3000-1000000 nm). Health Effects: Heating, Cataracts ('Glass Blower's Cataract'), Retinal burn, Erythema. LASER Hazards: Eye damage, Thermal burn, Electrical hazard. Classes of LASER (IEC 60825-1/ANSI Z136.1—2007): Class 1, 1M, 2, 2M, 3R, 3B, 4 (increasing hazard). Eye Protection from Lasers: Never stare directly into beam. Use laser safety goggles of suitable optical density (OD). Maximum Permissible Exposure (MPE): Highest power density (W/cm$^2$) considered safe. Radio-frequency/Microwave Radiation TLVs (ACGIH): Health Effects: Heating (deep into tissue), interference with CNS (vertigo, nausea). Basic restrictions on exposure SAR (Specific Energy Absorption Rate) in W/kg. 8. Industrial Hygiene & Safety - General Concepts 8.1 Industrial Hygiene Definition Science and art devoted to anticipation, recognition, evaluation, and control of workplace environmental factors or stresses that may cause sickness, impair health, or cause discomfort. Deals with hazards from physical, chemical, biological agents, and ergonomic factors. Health of workers, assessment of hazards. 8.2 Environmental Stresses in Workplace Physical Agents: Ionizing radiation, non-ionizing radiation, noise, inappropriate illumination, temperature/pressure extremes. Chemical Agents: Solvents, acids, caustics, alcohols. Biological Agents: Bacteria, mold, fungus, insect-related contaminants. Ergonomic Factors: Workstation/tool design, repetitive work. 8.3 Anticipation & Recognition of Hazards Requires knowledge of materials (MSDS), process flow, design/operating parameters, job site surveys, past experience. 8.4 Evaluation of Hazards Measurement of hazards. Necessary for: pinpointing operations, assessing concentrations, checking control effectiveness, recommending controls, statutory compliance. Methods: Qualitative Exposure Evaluation, Quantitative Exposure Monitoring (Personal Sampling, Area Sampling). 8.5 Industrial Hygiene Monitoring Methods Hazard/Agent Method Gas/Vapour/Fumes & other chemicals Gas detector tubes; Direct detecting sensors; Sampling and analysis Noise Sound Level Meter Illumination Lux Meter Heat stress WBGT Index measuring apparatus Dust Dust sampler Ventilation Air Velocity Meter 8.6 Occupational Exposure Limits (OEL) Permissible Exposure Limits (PEL): Mandatory limits by OSHA, USA. Permissible Limit on Exposure (PLE): Mandatory limits by The Factories Act 1948 (India). Threshold Limit Values (TLV): Recommended guideline values by ACGIH. 8.7 Threshold Limit Values (TLV) Types TLV-TWA (Time-Weighted Average): For 8-hour workday/40-hour week. Repeated exposures up to this level generally show no adverse effects. TLV-STEL (Short-Term Exposure Limit): 15-minute TWA. Not to be exceeded at any time. At least 60 minutes between exposures. Max 4 exposures per shift. TLV-C (Ceiling): Do not exceed for even an instant. 8.8 Control of Hazards Engineering Control: Process design changes, material substitution, enclosure, local exhaust ventilation. Administrative/Personal Control: Job rotation, training, work practices, PPE. Medical Control. 9. Heat Stress 9.1 Effects of Heat Stress Heat Exhaustion, Heat Cramp, Heat Stroke, Productivity Loss. Human comfort: $20^\circ C - 27^\circ C$ and $35-60\%$ relative humidity. 9.2 Heat Stress Indices Depends on: Air Temperature, Humidity, Radiant Temperature, Air Velocity, Metabolic Heat Production, Clothing Insulation. WBGT Index (Wet-Bulb Globe Temperature), Body Temperature, Heart Rate. 9.3 Prevention of Heat Stress Adequate water intake. Breaks in cool places. Learn signs/symptoms and respond early. Schedule heavy work in cool times. Move work to shade or cooler area. 10. Electrical Hazards 10.1 Primary Hazards Electrical Shock: Fibrillation (irregular heart beat), Respiratory tetanus (continuous muscle contraction). Burn Fire & Explosion 10.2 Secondary Hazards Fall of person from height. Fall of tools/objects. 10.3 Severity of Electrical Shock Depends on: Current magnitude, Duration, Path through body, AC/DC. Let Go Current: Max current at which a person can release a conductor ($\approx 9$ mA for male, $\approx 6$ mA for female). Electrical Resistance of Human Body: Dry skin: $100,000 \Omega$ or more. Wet skin: $1000 \Omega$. Internal body: $300 - 1000 \Omega$. Immersed in water: can be $300 \Omega$. Low voltage can be dangerous (e.g., $30$ V for $0.1$ A). 10.4 Arc Flash & Arc Blast High voltage arcs when electricity passes through air. Massive energy release burns bus bar, vaporizing copper ($\approx 67000$ times expansion), causing explosion. 10.5 Control Measures Most accidents from unsafe equipment/installation, unsafe environment, or unsafe work practices. Prevention: Insulation, guarding, grounding, electrical protective devices, safe work practices. 10.6 Circuit Protection Devices Limit or stop current automatically for ground fault, overload, or short circuit. Fuses: Melt when overheated, open circuit. Miniature Circuit Breaker (MCB): Automatically cuts off circuit on overload/short circuit. Residual Current Device (RCD)/Earth Leakage Circuit Breaker (ELCB): Instantly breaks circuit to prevent electric shock. 11. Fire & Explosion Hazards 11.1 Fire Triangle Fuel, Oxygen, Heat. 11.2 Fuel Sources Gases: Natural Gas, Propane, Butane, Hydrogen, Acetylene. Liquids: Gasoline, Kerosene, Turpentine, Alcohol, Paint, Varnish, Oils. Solids: Coal, Wood, Paper, Cloth, Wax, Grease, Leather, Plastic. 11.3 Oxygen Source Air, Oxidizers. 11.4 Heat Source Open Flame, Sun, Hot Surfaces, Sparks & Arcs, Friction, Chemical Action, Electrical Energy. 11.5 Fire Pyramid Adds "Chain Reaction" to the Fire Triangle. 11.6 Flash Point & Auto-Ignition Temperature Flash Point: Lowest temperature where vapor forms an ignitable mixture near liquid surface. Auto-Ignition Temperature: Lowest temperature where a flammable chemical ignites spontaneously without ignition source. 11.7 Fire and Explosion Hazards in a Nuclear Recycling Plant Zircaloy fines from fuel chopping. Hydrogen from battery banks. Flammable chemicals in processes. Combustible materials (furnace oil, diesel). Fire in electrical cables. Red oil formation (evaporator operation, heating of two-phase mixtures). 11.8 Flammability Limits Vapor-air mixtures ignite only within a specific range. Lower Flammable Limit (LFL)/Lower Explosion Limit (LEL): Below this, mixture is too lean. Upper Flammable Limit (UFL)/Upper Explosion Limit (UEL): Above this, mixture is too rich. 11.9 Fire Load Quantity of heat liberated per unit area when a building and its contents are completely burnt. Used to grade buildings by fire hazard and provide precautions. 11.10 Fire Resistance Rating (FRR) Measure of how long a material/assembly withstands a standard fire test (minutes/hours). Capacity of a construction element to maintain LOAD-BEARING FUNCTION, INTEGRITY, and THERMAL INSULATION. 11.11 Principles of Fire Extinction Starvation: Removal of unburnt material. Smothering: Cutting off oxygen supply. Cooling: Removal of heat. Breaking of Chain Reaction: Chemical process. 11.12 Classification of FIRE (IS:2190) Class A: Solid combustible materials (wood, paper, plastic). Class B: Flammable liquids (petrol, kerosene, solvents). Class C: Flammable gases under pressure (LPG, methane, hydrogen). Class D: Combustible metals (magnesium, zinc, sodium). 11.13 Suitability of Fire Extinguishers Class Extinguisher Class A Water (Gas Cartridge), Water (Stored Pressure), Dry Chemical Class B Mechanical Foam, Dry Chemical, Carbon Dioxide Class C Carbon Dioxide, Dry Chemical Class D Special Dry Powder (Ternary Eutectic Chloride) 11.14 Fire Safety Appliances Active Systems: Hose-reels, Fire hydrant and hose box, Fire Extinguishers, Automatic Fire Detection and Alarm System (FDAS), sprinklers. Passive Systems: Fire barrier, fire detectors, fire retardant paints. 12. Safety in the Use of Machines 12.1 Machine Safeguarding Safeguards are essential to protect workers from injuries caused by moving machine parts. Any part or process causing injury should be safeguarded; hazards must be eliminated or minimized. 12.2 Machines (Examples) Lathe, milling, grinding (rotation). Planer, shaper, press tool (reciprocating motion). Band saw (traversing motion). 12.3 Hazards Associated with Machines Struck by ejected parts. Entanglement (machine, material). Electrical hazards. Chemical hazards (cutting fluids, lubricants). Burns, cuts from materials/substances. Noise levels. Common injuries: Amputation, crushing, electric shock, hearing loss, ill health. 12.4 General Controls for Reducing Machine Hazards Hazard Identification. Work Procedures. Training and updates. Emergency Preparedness. 12.5 Training Equipment-specific training (safe use, maintenance, protective devices, emergency stops). Training on proper PPE use and maintenance. Only qualified and trained persons operate machines. Additional hazard-specific training (Lock Out/Tag Out, Noise, Lasers, radiation). 12.6 Causes of Accidents with Machinery Loose clothing, hair, jewelry caught. Ejected materials. Inadvertent starting. Slipping/falling into unguarded parts. Contact with sharp edges. Adjustments while operational. Ineffective lock-out/isolation. Unauthorized operation. Lack of preventive maintenance. 12.7 Mechanical Motions and Actions Dangerous moving parts in three areas: Point of operation: Where work is performed (cutting, shaping). Power transmission apparatus: Components transmitting power (flywheels, pulleys, belts). Other moving parts: Reciprocating, rotating, transversely moving parts. Motions: Rotating, Reciprocating, Transverse. 12.8 Control the Risk (Hierarchy of Controls) Elimination Substitution Engineering Controls Administrative controls Personal protective equipment 12.9 Requirements for Safeguards Prevent contact (hands, arms, body, clothing). Provide security (not easily removed/tampered). Protect from falling objects. Not create new hazards (e.g., sharp edges). Not create interference (allow lubrication without removal). 12.10 Methods of Machine Safeguarding Consider: Operation type, stock size/shape, handling method, work area layout, material type, production requirements. 12.11 Types of Guards Fixed Guards: Permanently in place (by fasteners requiring a tool). Simple, low maintenance. Distance Guards: Fixed guard preventing access through a barrier/fence. Interlock Guards: When opened, machine shuts off/disengages; cannot start until guard is back. Can use electrical, mechanical, hydraulic, pneumatic power. Adjustable Guards: Allow flexibility for various stock sizes. Self-adjusting Guards: Openings determined by stock movement; guard pushed away by stock, returns to rest. 12.12 Guard Placement Minimum distance between guard and danger point depends on mesh/opening size. 12.13 Machine Guarding Devices Control entry into the danger area. Types: Presence sensing device (photoelectric, electromechanical, pressure-sensitive body bars). Two hand control. Pullbacks/restraints. Moveable barriers (gates). Safety trip controls (tripwire cables). 12.14 Other Safeguards Lock Out / Tag Out Isolation System: Padlocks/tags on isolation switch to prevent startup during maintenance. Emergency Stop Controls: Prominent, accessible, red, require manual reset. 12.15 Administration Safe Operating Procedures, shut down procedures, maintenance schedules and records. 13. Laboratory Biosafety 13.1 Purpose Prevent unintentional exposure to pathogens/toxins or their accidental release. Involves containment principles, technologies, practices. 13.2 Principles of Biosafety Protect yourself, workers, patients, co-workers, and the environment. 13.3 Risk Assessment Process Determine containment level for biohazardous agent. Determining Factors: Virulence/Pathogenicity, Infectious dose, Environmental stability, Route of spread, Communicability, Quantity, Vaccine/treatment availability, Host range, Geographic considerations. 13.4 Chain of Infection and Means of Protection Reservoir of pathogen, Incubation period, Portal of escape, Transmission, Route of entry/infectious dose, Susceptible host. 13.5 Biological Agents and Routes of Transmission Category A: Hepatitis B (bloodborne). Category B: E. coli (food-borne). Category C: Influenza (direct/indirect contact, droplet, aerosol). 13.6 Biological Agent Characteristics Environmental stability (resistance to drying, disinfectants), Growth cycle (spores-vegetative). Infectious Dose Examples: Coxiella burnetii (10 organisms by inhalation), E. coli ($10^8$ by ingestion). 13.7 Risk Group Classification Risk Group Individual Risk Community Risk 1 no, low no, low 2 moderate low 3 high low 4 high high RG1: Unlikely to cause animal/human disease (e.g., Lactobacillus acidophilus). RG2: Pathogenic for humans, unlikely serious hazard, treatment available, limited spread (e.g., Staphylococcus aureus). RG3: Pathogenic, cause serious disease, effective treatment usually available, little person-to-person spread (e.g., Mycobacterium tuberculosis). RG4: Lethal, pathogenic agent, readily transmittable, no widely available treatment (e.g., Ebola virus). 13.8 Biosafety Containment Levels (BSL) BSL1: Basic teaching, research. BSL2: Primary health services; diagnostic, research. BSL3: Special diagnostic services, research. BSL4: Dangerous pathogen units. 13.9 Facility Design Overview - Secondary Barriers BSL1: Basic lab. BSL2: Basic lab + aerosol confinement (biosafety cabinet). BSL3: Containment lab (2 door separation, specific design elements). BSL4: Maximum containment lab (separate building, complex design). 13.10 Biosafety Level 1 (Minimum Risk) Practices: Good Laboratory Practices (PPE), hand washing, decontamination. Equipment: Open bench work, mechanical pipetting devices. PPEs: Goggles, gloves, lab coat/gown. 13.11 Biosafety Level 2 (Moderate Risk) Practices: PPE, restricted access. Equipment: Open bench + hood (BSC for aerosols), autoclave, strict waste dealing, biohazard symbols. PPEs: Lab coats, gloves, eye protection, face shields. Additional Precautions: Self-closing/lockable doors, non-fabric chairs, eyewash, negative airflow (non-recirculation recommended), autoclave within facility. 13.12 Biological Safety Cabinet (BSC) - Hood Primary barrier to protect product, personnel, environment. Equipment laid out to not restrict airflow. Aerosols/splashes performed within BSC. Not designed for chemical use, except minute volatile chemicals with canopy. Annual certification. Place all materials in cabinet before starting. 13.13 Autoclave & Waste Handling Autoclave is a secondary barrier for decontamination. Eyewash station present. 13.14 Biosafety Level 3 (Highly Risk) Practices: PPE, restricted access, special clothing, directional airflow. Equipment: Same as BSL2. PPEs: Goggles, gloves, respirators may be required. Lab Design: 2 door entry (ante-room), solid cleanable surfaces, coved floors, sealed penetrations, hands-free sink, eyewash/shower, autoclave, negative airflow ($>12$ air changes/hour), dedicated exhaust. 13.15 Biosafety Level 4 (Life-Threaten Disease) Practices: PPE, restricted access, special clothing, airlock entry, shower exit, special waste disposal. Equipment: Autoclave, Class III hood, filtered air. PPEs: Full-body, air-supplied positive pressure suit. Extremely isolated (separate building/zone), dedicated supply/exhaust, vacuum lines, decontamination systems. 13.16 Disinfection Requirements depend on experimental work and agent nature. Contact time and concentration are specific to material/manufacturer. 13.17 Ultraviolet Lamps in BSCs Not required/recommended if BSC operated properly. If installed: Clean weekly, check intensity periodically, turn off when room occupied. 13.18 Biohazard Work Area Mark with warning sign and contact information. 14. Industrial Safety Management 14.1 Definition Management of activities to reduce risks and injuries in industry. Involves operation & maintenance practices and work culture. Team effort. 14.2 Importance Increases productivity, prevents loss of life and man-hours. 14.3 Industrial Hygiene vs. Industrial Safety Industrial Hygiene: Identifying, analyzing, controlling stressors leading to injury/illness. Industrial Safety: Policies/plans to meet challenges identified by hygienists; preventing accidents/injuries. 14.4 Historical Context Hammurabi (18th Century BC): Rulings pertinent to safety (e.g., builder's responsibility). Dracon (7th Century BC): Judgements in accident cases. H.W. Heinrich: Domino Theory (Injury Causation Model). 14.5 The Domino Theory (Heinrich’s Injury Causation Model) Sequence: Social Environment and Ancestry $\rightarrow$ Fault of Person $\rightarrow$ Unsafe Act or Unsafe Condition $\rightarrow$ Accident $\rightarrow$ Injury. Removal of a key factor stops propagation and prevents injury. 14.6 Industrial Safety in India First Indian Factories Act 1881: Focused on child welfare (age, working hours, rest, dangerous parts fencing, accident reporting). The Factories Act 1948: Ensures factory safety, fair worker treatment (work hours, safety, welfare, health, administration, funds, standards). 14.7 The Accident Unplanned, unwelcomed event interrupting normal activity. Not all cause injury. Rate of occurrence and consequences can be controlled by planning. 14.8 Hazard Definition Any condition that may result in or contribute to accident severity. 14.9 Accident Prevention Programme Formal organized effort to prevent accidents. 14.10 Outcomes of Accidents Negative: Death, injury, disease, damage to equipment/property, litigation costs, lost productivity. Positive: Accident investigation, changes to safety programs. 14.11 Hazards Classification Inherent Properties: Temperature, pressure, levels, corrosive, explosive, toxicity. Environmental Factors: Cyclone, lightning, earthquakes, flooding, tsunami. Failures: Material failure, human failures. 14.12 Costs of Accidents Direct Costs: Medical, compensation, damage to machines. Indirect Costs: (3 to 4 times greater) Time lost by assistants, investigation time, loss of production. 14.13 Three Basic Causes of Accidents Poor Management Safety Policy & Decisions. Personal Factors (lack of knowledge/skill, improper attitude). Environmental Factors (unsafe conditions, poor work standards). These lead to Unsafe Act and/or Unsafe Condition, resulting in unplanned energy release/hazardous material release, causing Accident, then Personal Injury/Property Damage. Causative Analysis: Unsafe Act = 80%, Unsafe Condition = 18%, Natural Cause = 2%. 14.14 Unsafe Condition Examples Unsafe construction, lack of machine guards, inadequate guarding, defective working conditions, poor layout, overcrowding, no PPE, unsafe lighting, hazardous substance storage. 14.15 Unsafe Act Examples Working without authority, failure to secure machinery/material, rendering safety devices inoperative, placing objects unsafely, fooling, using equipment unsafely, adjusting moving machinery, failure to use PPEs. 14.16 Accident Prevention Programme (BARC Example) Recording & Database Management of IOD (Injury on Duty) cases. Investigations of Disabling Injuries, Near Misses, unusual occurrences. Analysis of injuries (agency, type, nature, unsafe act/condition). 14.17 Injury Definitions Injury on duty: Any injury arising out of and in the course of employment. First-aid injury: Needs only first-aid. Disabling injury (Lost-time injury): Results in death, permanent total/partial disability, or temporary total disability for one or more full days beyond the day of injury. 14.18 Frequency Rate (FR) & Severity Rate (SR) FR: Number of disabling injuries per million man-hours of employee exposure. $FR = \frac{\text{Number of disabling injuries}}{\text{Man-hours worked}} \times 10^6$. SR: Number of man-days lost or charged per million man-hours. (Fatal/permanent total disability = 6000 man-days). $SR = \frac{\text{Number of man-days lost}}{\text{Man-hours worked}} \times 10^6$. Injury Index: $(FR \times SR) / 1000$. 14.19 Safety Appraisal Measurement of safety performance. Quantitative (FR, SR) and Qualitative (inspection, audits, review) approaches. 14.20 Accident Investigation Purpose Finding causes, preventing recurrences, determining cost, checking compliance. 14.21 Eliminating Unsafe Acts and Conditions Identify personal and job factors. Checklists. Corrective actions. 14.22 Accident Reporting Include all injuries, illnesses, first-aid incidents, near-misses. Involve management and employees. Develop/implement corrective actions. 14.23 Facility Inspections Inspect for unsafe conditions regularly. Document corrections. Involve employees. Implement statutory requirements. 14.24 Safety Committee Administration, certified, and classified employees. Reviews safety programs, procedures, accident reports. Suggests improvements, reports observations. 14.25 Safe Work Practices Develop for each job. Perform Hazard Analysis. Inspect equipment/work area. List required PPE. Reference other safety procedures. 14.26 Training Safety orientation for new employees. When new processes/procedures introduced, as required by regulations, when safety performance slips, after an accident. 14.27 Recordkeeping Safety training, hazard analysis, safe work practices, facility inspections, safety committee recommendations, accident investigations. 14.28 Program Evaluation Review effectiveness, update annually/with significant changes. Involve employees. 14.29 PPE Selection Choose right type for the job. 14.30 Accident and Responsibility Responsibility intensity decreases from Management to Worker. Chances of accident increase from Management to Worker. 15. Chemical Hazards 15.1 Introduction to Chemical Hazards Chemicals are ubiquitous. Can be hazardous to health, cause fires/explosions. Categories: Fire and Explosion Hazards, Health Hazards. 15.2 Fire and Explosion Hazards - Chemical Groups Flammable chemicals, Explosive chemicals, Gases under pressure, Oxidizing agents, Water sensitive chemicals, Pyrophoric chemicals. 15.3 Flammable Chemicals Liquids: Crude oil, naphtha, hydrocarbons, alcohols, benzene, acetone, gasoline. Solids: Camphor, Phosphorus. Gases: H$_2$, C$_2$H$_2$, LPG. Flammable: Liquid with flashpoint below $100^\circ F$ ($37.8^\circ C$). Combustible: Liquid with flashpoint at or above $100^\circ F$ ($37.8^\circ C$). Ignition Sources: Naked Flames, Static Electricity, Electrical Spark. Flammable Range: Concentration of vapor in air between LFL and UFL where ignition can occur. 15.4 Explosives Sudden release of pressure, gas, heat from shock, pressure, high temperature. Effect: Shock wave/blast wave creates overpressure, causing damage/injury. e.g., Nitro explosives (TNT, Picric acid), Nitric explosives (NaNO$_3$, NH$_4$NO$_3$). 15.5 Gases Under Pressure Liquified gases: LPG, N$_2$, He, NH$_3$, Cl$_2$, Ar. Non-liquified gases: SO$_2$, NO$_2$, N$_2$, Air, O$_2$, H$_2$, He, Ar. Governed by Gas Cylinder Rule: 1994. 15.6 Oxidizing Agents Cause other substances to burn more easily by providing oxygen. e.g., Chlorates, Nitric Acid, Peroxides, Permanganates. 15.7 Dangerously Reactive Material Vigorous polymerization, condensation, decomposition (e.g., Ethylene Oxide). Self-reactive under increased temperature, pressure, shock (Organic Azides). Vigorously react with water to produce fire/hazardous gas (Na, K, Cyanides, Metal hydrides). 15.8 Pyrophoric Materials Produce sparks when rubbed, or burn spontaneously in air. Ignition activity related to surface area, particle size, purity, oxides, moisture. Metal dust clouds (e.g., Zr, Mg) can explode when dispersed in air with an ignition source. 15.9 Health Hazards Determined by: Physical forms, Routes of exposure, Types of exposure, Dose and Duration, Reaction and interaction, Sensitivity. 15.10 Physical Classification of Chemicals Solids, Liquids, Vapours, Aerosols. 15.11 Exposure Routes Inhalation: Gases, vapours, dusts, aerosols (via trachea, lungs). Ingestion: Dusts, liquids (via esophagus to stomach). Skin contact / Absorption: Spillage of dusts and liquids. 15.12 Target Organs Lung, Heart, Digestive tract, Liver, Kidneys, Ear, Eye, Skin, Nose, Mouth, Reproductive system, CNS. Examples: Carbon Monoxide (red blood cells), Hydrogen cyanide (skin), Epoxy resin (skin dermatitis), Chromic acid (ulcer/dermatitis), Trichloroethylene (dissolves fat from skin), Acids/alkalis (corrosive burns), Lead/Mercury/Arsenic (poisoning). 15.13 Chemical Fate in Body Excreted: Urine, exhaled via lungs, sweat, nails/hair. Stored: Blood/lymph, bones (heavy metals), fats (chlorinated hydrocarbons), liver/kidneys. Metabolized: Chemical reaction, potentially leading to tissue damage/toxic reaction. 15.14 Types of Exposure Acute exposure: Large single dose, quick reaction, emergency medical care (burning, poisoning). Chronic exposure: Continuous/repeated small amounts, worsen over time due to delayed effects. 15.15 Hazardous Effect of a Chemical Local effects: Eyes, skin, respiratory tract (e.g., acids, alkalis). Systemic effects: Heart, brain, liver, kidneys (via bloodstream, e.g., heavy metals). Latent effect: Undeveloped effect until incubation period elapses. 15.16 Toxicity Ability of a chemical to injure living organisms. Factors: Type of exposure, Physical/chemical properties, Dose, Duration, Sensitivity (age, sex, health, etc.). Toxicity for Gases/Aerosols: Depends on Concentration ($C$), Exposure Time ($t$), and the specific LC50. Dosage = $C \times t$. 15.17 Measurement of Toxicity Lethal Dose (LD$_{50}$): Amount (mg/kg) to kill 50% of exposed animals. Lethal Concentration (LC$_{50}$): Concentration (ppm) to kill 50% of exposed animals. Immediately Dangerous to Life and Health (IDLH): Max concentration for 30-minute escape without irreversible health effects. 15.18 Reaction and Interaction Interaction: Exposure to multiple substances causes different effect than individual sum. Synergism: Combined effect greater than sum of individual effects. Antagonism: Combined effect less than sum of individual effects. 15.19 Classification of Toxic Materials Irritants: Irritation of respiratory tract, eyes, throat (e.g., Ammonia, Acids, NOx). Asphyxiants: Simple: Dilute oxygen (e.g., Methane, N$_2$, CO$_2$). Chemical: Deprive body cells of oxygen (e.g., CO, H$_2$S, HCN). Anaesthetics and Narcotics: CNS depression (e.g., Chloroform, Nitrous oxide). Systemic Poisons: Affect specific systems (e.g., Benzene-blood, Methanol-nerve, Asbestos-lung, Pb-toxic metal). Pneumoconiosis: Physically deposited in air sacs (e.g., Silica, Asbestos). Carcinogens: Cancer-causing (e.g., Benzene, Nickel compounds, Arsenic). 15.20 ACGIH Carcinogen Categories A1: Confirmed human carcinogens. A2: Suspected human carcinogens. A3: Animal carcinogens. A4: Not classified as human carcinogens. A5: Not suspected to be human carcinogens. 16. Cryogenics 16.1 Introduction Refers to phenomena, processes, techniques, or apparatus at temperatures below 120K. 16.2 Usage Cryogenic cooling (liquid nitrogen, solid CO$_2$). Cryosurgery. Preserving biological materials. MRI systems (superconducting magnets cooled to 4.2 K). 16.3 Hazards Freezing of Tissue (Frost Bite): Direct contact with cryogenic fluids/equipment. Permanent cell damage. Hypothermia: Lowering of body temperature from prolonged exposure to large spill. Asphyxiation: Cryogens expand $\approx 700$ times on evaporation, displacing oxygen in confined spaces. Prevention: Proper ventilation, certified procedures, breathing apparatus, oxygen monitoring. 16.4 Handling of Cryogens Always through approved procedures. Risks: Splashing, clothes trapping cold fluid, cold parts contact, fluid dispersion on floor, oxygen displacement. Confined spaces (e.g., lifts) with cryogens pose anoxia/asphyxiation danger. 16.5 First Aid for Cryogenic Exposure Do NOT attempt confined space rescue if unconscious; call emergency services. Move dizzy/unconscious person to well-ventilated area. Apply artificial respiration if breathing stops. Keep casualty warm and at rest. 16.6 Condensation Hazards Causes: Cryogens condense water vapor and CO$_2$. Liquid air (with oxygen) condenses at liquid nitrogen temperatures. Argon, N$_2$, O$_2$ condense to solids at liquid neon/hydrogen/helium temperatures. Problems: Cold embrittlement of equipment, plugged pipes/relief openings, fire/explosion hazard from oxygen-enriched condensed air, explosive ozonides in nuclear radiation flux. Prevention: Purging system before cooling, maintaining internal pressure above external, vacuum space protection, thermal insulation. 16.7 LOX (Liquid Oxygen) Handling Light blue, odorless, transparent liquid. Not shock sensitive, does not decompose. Strong oxidizer: Non-combustible substances in air burn vigorously in LOX. Breathing $> 60\%$ oxygen can cause lung damage. Materials for LOX service: Consider ignition temp, impact sensitivity, ignition sources. Nickel and its alloys are resistive to ignition/combustion. 16.8 Disposal of Cryogenic Liquids Do NOT pour down sink (can crack pipes). Do NOT store/vaporize in enclosed areas (fridges, cold rooms, basements). Ensure well-ventilated area for vaporization. 17. Occupational Exposure Limits (OEL) for Chemicals 17.1 Threshold Limit Values (TLV) Recommended guideline values by ACGIH. Refer to airborne concentrations where nearly all workers may be repeatedly exposed without adverse effect. TLV-TWA, TLV-STEL, TLV-C (defined above). 17.2 TLV of Mixtures For a mixture of chemicals A, B, C with individual TLVs $T_1, T_2, T_3$ and concentrations $C_1, C_2, C_3$: Effective TLV = $(C_1/T_1) + (C_2/T_2) + (C_3/T_3)$. 17.3 Toxicity Indices LD$_{50}$: Single dose (mg/kg) lethal to 50% of animals. LC$_{50}$: Concentration lethal to 50% of animals. IDLH (Immediately Dangerous to Life & Health) Concentration: Exposure likely to cause death, permanent adverse effects, or prevent escape within 30 minutes. 18. MSDS Format (16 Sections) Manufacturer and supplier identification, Contact information. Hazard(s) identification. Composition/information on ingredients. First-aid measures. Fire-fighting measures. Accidental release measures. Handling and storage. Exposure controls/personal protection. Physical and chemical properties. Stability and reactivity. Toxicological information. Ecological information. Disposal considerations. Transport information. Regulatory information. Other information. 19. Commonly Used Symbols & Codes 19.1 NFPA System (National Fire Protection Association) Diamond-shaped, color-coded (Blue=Health, Red=Flammability, Yellow=Reactivity, White=Special). Number-coded in colored diamonds. 19.2 UN Code for Transport of Dangerous Goods (IS 1446: 2002) Explosives Compressed gases Flammable liquids Flammable solids Oxidising substances Toxic substances Radioactive substances Corrosives Miscellaneous dangerous substances 20. Handling of Chemicals 20.1 General Principles Know hazardous properties. Store minimum needed quantity. Incompatible chemicals stored separately (e.g., oxidizers away from flammables). Keep chemicals well-packed, tightly corked, in well-ventilated areas. Ensure proper and intact labels. Wear appropriate PPE (aprons, labcoats, boots, gloves, goggles, face shield). Use fume hoods for fumes, toxic vapours, volatile/decomposable substances. Prompt cleaning of leaks/spills. 20.2 Fume-hoods Not for material storage. For experiments with fumes/toxic vapours, volatile/decomposable substances. Ensure unblocked airflow/vents. Minimum face velocity: $0.5$ m/s when sash front $30$ cm open. 20.3 Ventilation System Generally 3-6 air changes per hour (ACH) in hazardous chemical areas. Flammable storage: flammable vapour concentration $ Toxic chemicals: airborne concentration $ 20.4 Control Measures Engineering: Ventilation (Dilution & LEV), Fume hood ($3-6$ ACH minimum, $0.5$ m/s face velocity). Administrative/Personal: Health education, judicious PPE use, change rooms, bathing facilities. Medical: At employment, periodic intervals, return to work, termination. 20.5 Methods for Evaluation (Chemical Exposure) Instrumental Methods: Direct-reading monitors (particulates, H$_2$S, O$_2$, gases/vapours, organic solvents). Air Sampling Methods: Known air quantity drawn through bubblers, trapped chemical estimated analytically. Biochemical/physiological tests. 20.6 Chemical Incompatibility Chart Nitric acid + Flammable = Fire. Nitric acid + Metal = Hydrogen gas. Nitric acid + Water = Violent reaction. Acids, bases, flammables stored separately. Mineral acids from organic acids. Organics from oxidizers. 20.7 Carrying Chemicals Containers packed in outside container/bucket. Use freight elevators if possible; avoid stairs/crowded routes. Carts for large amounts. Acid containers $> 500$ mL carried in acid carrier. 20.8 Eating, Smoking, Cosmetics and Horseplay Prohibited in chemical areas. Do not store food/beverages with chemicals. Avoid practical jokes. 20.9 Working Alone Avoid hazardous operations alone. Do not work alone if not trained. 20.10 Exit Procedures Wash hands carefully after handling chemicals; face and forearms if needed. 20.11 Signs and Labels Warning signs at special hazard areas/equipment. Contents and hazards on containers. Signal word (Danger!, Warning!, Caution!). Instructions for contact, fire, spill, leak. First-Aid/antidote. Locations: safety showers, eyewash, first aid equipment, emergency numbers, hazards, safety precautions on door. 20.12 Monitoring (Chemical Exposure) Regular instrumental monitoring of airborne concentrations. When testing/redesigning fumehoods/ventilation. When highly toxic substance is used regularly. 20.13 First Aid (Chemical) Personnel trained in basic first aid. Basic first aid supplies maintained. 20.14 Records (Chemicals) Inventory maintained/updated annually. Accidents/incidents documented in monthly QA report. Injury on duty forms filled. 20.15 Information (Chemical Safety) Methods to detect presence/release of hazardous chemical. Physical/health hazards (signs/symptoms of exposure). Measures to protect (PPEs). Material Safety Data Sheet (MSDS). 20.16 Examples of Hazardous Chemicals and their TLVs Ammonia: Irritation, lung damage, dermatitis. TWA = 25 ppm, STEL = 35 ppm. Formaldehyde: Sore throat, coughing, skin irritation, blurred vision. Ingestion causes abdominal pain. Suspected carcinogen. TLV Ceiling = 0.3 ppm. Hydrazine: Highly irritating to respiratory tract/eyes, severe skin burns, corrosive, liver damage. TLV = 0.01 ppm. Tributyl Phosphate: Corrosive to skin, eyes, respiratory tract. Ingestion causes abdominal pain. TWA = 0.2 ppm, STEL = 0.5 ppm. 20.17 Long-Term Storage Considerations (Peroxide Formers) Ethers (Isopropyl, Diethyl Ether), Acetals, Olefins with Allylic Hydrogen, Dienes, Ureas, Amides, Lactams, Alkali Metals and Alkoxides, Vinyl Monomers/Halides/Acrylates/Methacrylates. 21. Disposal of Chemicals 21.1 Philosophy Minimize waste generation (substitution). Reduce volume (recycling, reuse, recovery). Treat waste to stabilize, immobilize, contain, or destroy hazardous properties. Dispose residues with minimum environmental impact. Store safely un-treatable hazardous waste. 21.2 Methods Dilute & Disperse: Deactivate/neutralize some liquid wastes (acids/bases); dilute with water. Chemical Incineration: For organic liquid chemical waste. Cement-based Solidification: Mixing hazardous waste with cementitious binders to immobilize. Simple, low cost. Landfill: Disposal in ground; natural setting selected to minimize escape to groundwater. Vitrification: Converts liquid chemical waste into solid, stable glass. Waste mixed with silica, heated ($2000^\circ C$), cooled to solid glass. 21.3 Prohibited Disposal to Public Drainage System Flammable liquids. Liquids damaging wastewater facilities (pH). Highly viscous materials causing obstruction. Radioactive materials. Materials creating strong odor. Wastewater significantly raising system temperature. Pharmaceuticals or endocrine disruptors. 21.4 Unlabeled Chemicals ("Orphan" Waste) Pre-screen for crystals (peroxide), radioactivity, bio-waste. Avoid if possible; requires analysis before disposal. If handling: Wear gloves, goggles, hood, mask. Screen for air/water reactivity, solubility, flammability, corrosivity, pH. 21.5 Bhopal Gas Leak (1984) World's worst industrial accident. Methyl Isocyanate (MIC) leak. Water entered MIC tank, causing exothermic reaction. Thousands died, hundreds of thousands maimed. Pollutants caused long-term health issues. Causes: Inadequate safety norms, water/MIC isolation failure, untrained workers. 21.6 Gujarat Chemical Industry Explosion (2020) Dimethyl sulphate and Nitric acid mixed (incompatible, exothermic reaction). Increased pressure, explosion, hydrogen trolley also exploded. Causes: Incompetent/untrained worker, management's casual approach, failure of risk assessment, inadequate training, lack of positive isolation.