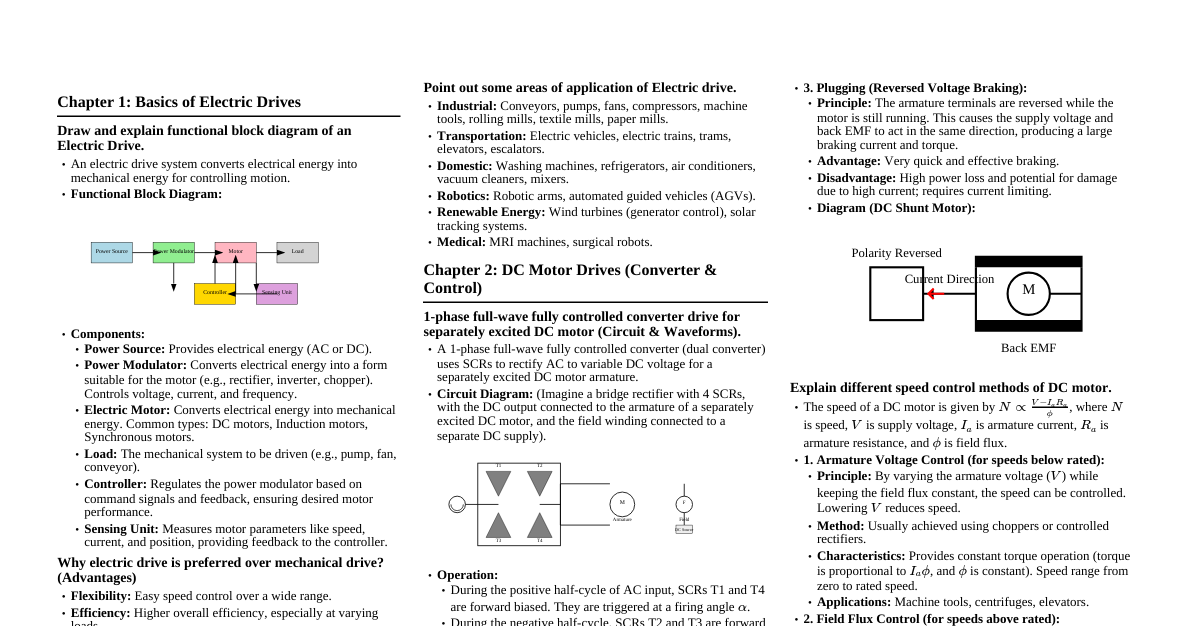

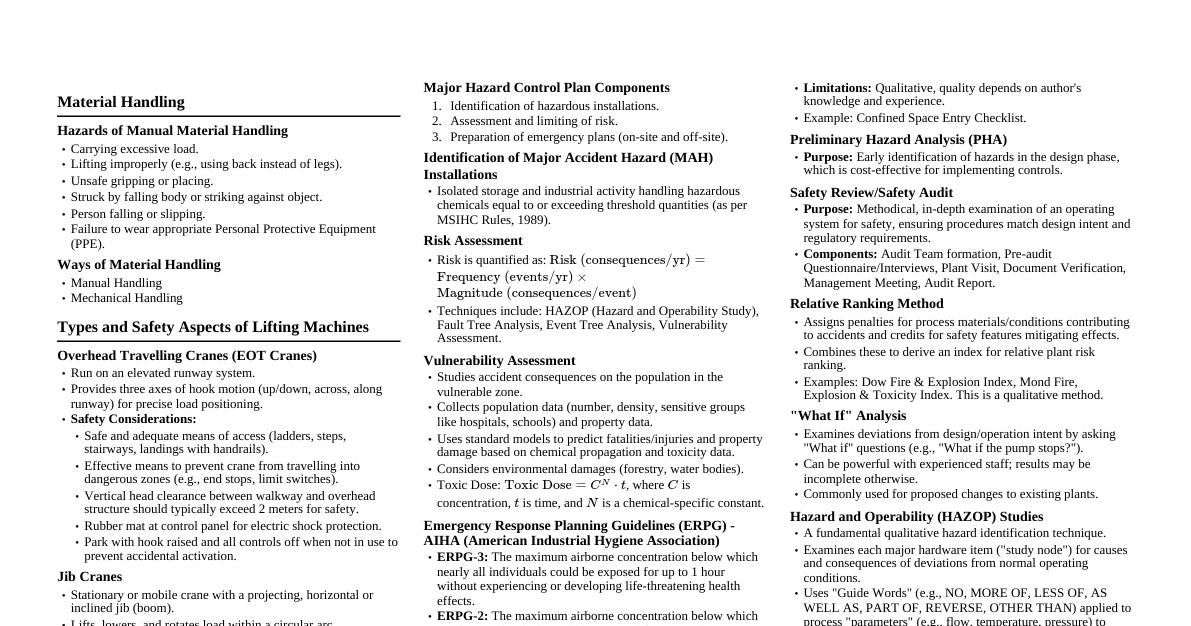

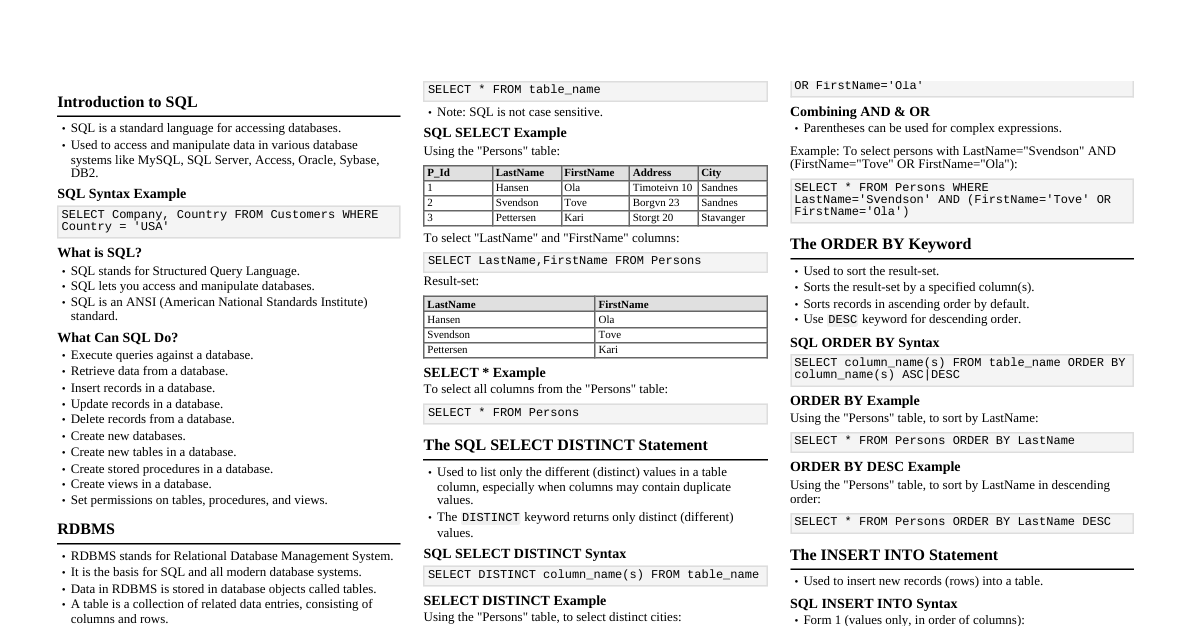

Chapter 1: Basics of Electric Drives Functional Block Diagram of an Electric Drive An electric drive system converts electrical energy into mechanical energy for controlling motion. It typically consists of several key components: Power Source: Provides electrical energy (e.g., AC mains, DC supply). Power Modulator: Controls the power flow from the source to the motor. It can be a converter, inverter, chopper, or cycloconverter. Motor: Converts electrical energy into mechanical energy (e.g., DC motor, AC induction motor, synchronous motor). Load: The mechanical system driven by the motor (e.g., fan, pump, conveyor). Sensing Unit: Measures motor parameters like speed, current, position. Control Unit: Processes feedback from the sensing unit and generates control signals for the power modulator to achieve desired motor performance. Power Source Power Modulator Motor Load Sensing Unit Control Unit Advantages of Electric Drive over Mechanical Drive Flexibility and Control: Offers precise and flexible control over speed, torque, and position. Efficiency: Generally more energy-efficient, especially with variable speed applications. Smooth Operation: Provides smoother acceleration and deceleration, reducing mechanical stress. Cleaner Environment: No exhaust fumes or noise compared to internal combustion engines. Remote Control: Can be easily controlled remotely or automated. Reduced Maintenance: Fewer moving parts lead to lower maintenance requirements. Quick Response: Faster dynamic response to changes in load or desired speed. Automation: Easily integrated into automated systems and processes. Comparison between AC Drives and DC Drives Feature DC Drives AC Drives Motor Type DC motors (shunt, series, compound, permanent magnet) AC motors (induction, synchronous, permanent magnet AC) Speed Control Armature voltage control, field flux control Voltage/Frequency (V/f) control, vector control, direct torque control Complexity Simpler control for basic speed, but commutator adds complexity/maintenance to motor More complex control algorithms, but robust and simple motor construction Maintenance High (brushes, commutator) Low (brushless, rugged construction) Efficiency Good, but losses in commutator and brushes High, especially with modern control techniques Size/Weight Larger and heavier for same power rating Smaller and lighter for same power rating Applications High starting torque, wide speed range (e.g., traction, hoists, paper mills) Pumps, fans, compressors, machine tools, general industrial applications Need for Electric Drive System Electric drive systems are crucial for: Energy Efficiency: Optimizing energy consumption by matching motor speed to load requirements. Process Control: Achieving precise control over industrial processes, improving product quality and consistency. Automation: Enabling automation of various tasks, reducing human intervention and increasing productivity. Versatility: Adapting to a wide range of applications with varying speed and torque demands. Environmental Benefits: Reducing pollution and noise compared to mechanical or hydraulic systems. Cost Savings: Lower operating costs due to efficiency and reduced maintenance. What is an Electric Drive / Electric Drive System? An electric drive is an electromechanical system that converts electrical energy into mechanical energy to control the motion of a machine or process. It typically comprises an electric motor, a power converter, a control unit, and the driven load. Its primary function is to provide controlled mechanical power to a load. Functions of Power Modulator The power modulator (e.g., converter, inverter, chopper) in an electric drive system performs several critical functions: Voltage Control: Adjusting the voltage supplied to the motor to control its speed or torque. Current Control: Regulating the current to the motor for torque control and protection. Frequency Control: For AC motors, varying the frequency of the supply to control speed (V/f control). Power Factor Improvement: Some modulators can improve the input power factor. Energy Recovery: In braking modes, some modulators can return energy from the motor back to the supply (regenerative braking). Starting and Braking: Providing smooth starting and controlled braking operations. Protection: Protecting the motor and power source from overcurrent, overvoltage, etc. Areas of Application of Electric Drives Industrial Applications: Machine tools (lathes, milling machines) Pumps and fans Conveyors and elevators Textile mills, paper mills, steel mills Robotics and automation Transportation: Electric vehicles (cars, buses, trains) Electric ships and aircraft Household Appliances: Washing machines, refrigerators, air conditioners Blenders, vacuum cleaners Renewable Energy: Wind turbine generators Solar tracking systems Medical Equipment: MRI scanners Surgical robots