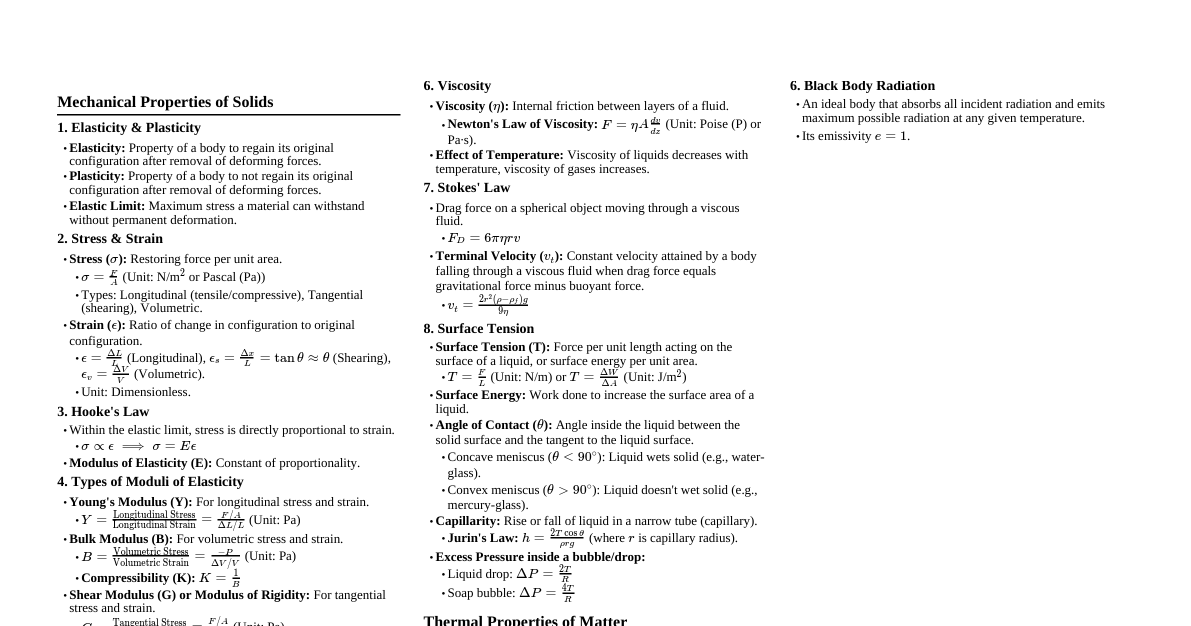

Mechanical Behavior Overview Definition: Response/deformation of material to applied load/force. Loading Types: Static (constant magnitude), Dynamic (varies with time). Deformation Types: Elastic (temporary), Plastic (permanent), Anelastic (time-dependent temporary), Creep (time-dependent permanent), Fatigue (fluctuating/alternating load). Key Properties: Stiffness, strength, hardness, ductility, toughness. Stress & Strain Tensile Stress ($\sigma$): Force ($F_t$) perpendicular to original cross-sectional area ($A_o$). $$\sigma = \frac{F_t}{A_o}$$ Shear Stress ($\tau$): Force ($F_s$) parallel to original cross-sectional area ($A_o$). $$\tau = \frac{F_s}{A_o}$$ Tensile Strain ($\epsilon$): Change in length ($\Delta L$) divided by original length ($L_o$). $$\epsilon = \frac{\Delta L}{L_o}$$ Shear Strain ($\gamma$): Tangent of the strain angle ($\theta$). $$\gamma = \tan \theta$$ Units: Stress in N/m$^2$ (Pa) or lbf/in$^2$ (psi), Strain is dimensionless. Elastic Properties Hooke's Law: $\sigma = E\epsilon$ (for linear elastic materials). Young's Modulus ($E$): Modulus of elasticity, stiffness, resistance to elastic deformation. Slope of linear stress-strain curve. Poisson's Ratio ($\nu$): Ratio of lateral strain to axial strain. $$\nu = -\frac{\epsilon_L}{\epsilon}$$ (For isotropic materials, $\nu$ is typically 0.25-0.35 for metals, max 0.50). Shear Modulus ($G$): $\tau = G\gamma$. Modulus of rigidity. Bulk Modulus ($K$): $P = -K \frac{\Delta V}{V_o}$. Resistance to volume change under hydrostatic pressure. Relations for Isotropic Materials: $$G = \frac{E}{2(1+\nu)}$$ $$K = \frac{E}{3(1-2\nu)}$$ Bi-modulus materials: Different elastic properties in tension and compression. Secant & Tangent Modulus: Used for non-linear elastic behavior. Tangent Modulus: Slope of stress-strain curve at a specified stress level. Secant Modulus: Slope of a secant from origin to a given point on the curve. Material Anisotropy Isotropy: Uniform properties in all orientations (2 independent elastic constants). Anisotropy: Properties vary with direction (e.g., rolled metals, single crystals). Orthotropy: A subset of anisotropic materials with three planes of symmetry (9 independent elastic constants). Stress-Strain Diagram Features Elastic Limit: Maximum stress material can sustain without permanent deformation. Proportionality Limit: Highest stress where stress and strain are directly proportional. Yield Strength ($\sigma_y$): Stress at which noticeable plastic deformation begins. Often defined by a 0.2% offset proof stress. Proof Stress: Stress to produce a defined amount of permanent residual strain (e.g., 0.2% Proof Stress). Yield Point Phenomenon: Upper and lower yield points seen in some materials (e.g., mild steel) due to dislocation anchoring by solute atoms (Cottrell-Bilby model). Necking: Localized reduction in cross-sectional area that occurs after ultimate tensile strength. Ultimate Tensile Strength (UTS): Maximum stress on the engineering stress-strain curve. True Stress ($\sigma_T$): Load divided by instantaneous cross-sectional area. $$\sigma_T = \sigma (1+\epsilon)$$ True Strain ($\epsilon_T$): $\ln(L_i/L_o)$. $$\epsilon_T = \ln(1+\epsilon)$$ Strain Hardening: Increase in strength due to plastic deformation (cold work). Described by power law: $\sigma_T = K \epsilon_T^n$. Ductility & Brittleness Ductility: Degree of plastic deformation sustained before fracture. Measured by: Percentage Elongation (%EL) and Percentage Reduction in Area (%RA). $$\%EL = \frac{L_f - L_o}{L_o} \times 100$$ $$\%RA = \frac{A_o - A_f}{A_o} \times 100$$ Brittleness: Little or no plastic deformation upon fracture. Hardness Definition: Resistance to permanent deformation by indentation or scratching. Proportional to UTS. Tests: Brinell Hardness (HB): Large ball indenter, measures diameter of indent. Rockwell Hardness: Diamond cone or steel ball indenter, measures depth of indent. Scales A, B, C. Toughness Definition: Capacity of a material to absorb energy plastically before fracturing. Area under the stress-strain curve. Modulus of Resilience ($U_r$): Energy absorbed per unit volume up to yielding. For linear elastic, $U_r \approx \frac{1}{2}\sigma_y \epsilon_y$. Impact Testing: Measures energy absorbed to fracture (Charpy, Izod tests). Determines ductile-brittle transition. Ductile-Brittle Transition Temperature (DBTT): Temperature below which a material becomes brittle (relevant for BCC metals, not FCC). Plastic Deformation Mechanisms Dislocation Motion: Plastic deformation occurs primarily by movement of dislocations (slip). If dislocations can't move, plastic deformation doesn't occur. Slip System: Combination of a slip plane (highest planar density) and a slip direction (highest linear density). FCC: {111} planes, directions (12 systems). BCC & HCP: Other slip systems exist. Resolved Shear Stress ($\tau_R$): Shear stress component acting on a slip plane in the slip direction due to an applied tensile stress ($\sigma$). $$\tau_R = \sigma \cos \phi \cos \lambda$$ ($\phi$: angle between tensile axis and slip plane normal; $\lambda$: angle between tensile axis and slip direction). Critical Resolved Shear Stress ($\tau_{CRSS}$): Minimum resolved shear stress required to initiate slip. Polycrystals vs. Single Crystals: Polycrystals are stronger due to grain boundaries acting as barriers to dislocation motion. Dislocation Motion in Different Materials: Metals: Easiest (non-directional bonding, close-packed directions). Covalent Ceramics: Difficult (directional bonding). Ionic Ceramics: Difficult (need to avoid like-charged neighbors). Strengthening Mechanisms Goal: Restrict dislocation motion to make materials harder and stronger. 1. Grain Size Reduction: Smaller grains mean more grain boundaries, which impede dislocation movement. Hall-Petch Equation: $\sigma_y = \sigma_o + k_y d^{-1/2}$ ($\sigma_o, k_y$ are constants, $d$ is grain diameter). 2. Solid Solution Strengthening: Impurity atoms (substitutional or interstitial) distort the lattice, creating local strains that interact with dislocations, hindering their movement. 3. Precipitation Hardening: Hard, small precipitate particles act as obstacles to dislocation motion. Dislocations either cut through or bow around precipitates (Orowan looping). 4. Strain Hardening (Cold Work): Plastic deformation at room temperature. Increases dislocation density, leading to entanglement and increased resistance to further dislocation motion. Increases $\sigma_y$ and UTS, decreases ductility. Heat Treatment After Cold Working 1. Recovery: Internal strains are relieved, dislocation density reduced by annihilation. Mechanical properties largely unchanged. 2. Recrystallization: Formation of new strain-free, equiaxed grains from deformed grains. Decreases strength/hardness, increases ductility. Occurs above recrystallization temperature ($T_R$). 3. Grain Growth: At longer times/higher temperatures, average grain size increases, reducing grain boundary energy. Further decreases strength. Recrystallization Temperature ($T_R$): Temperature at which a cold-worked metal fully recrystallizes in ~1 hour ($0.3 T_m Hot Working: Deformation above $T_R$. Cold Working: Deformation below $T_R$. Anelasticity (Time-Dependent Elasticity) Material returns to original shape after transient load, but with a time delay. Due to time-dependent microscopic/atomistic processes. Significant in some polymers (viscoelasticity). Fracture Ductile Fracture: Accompanied by significant plastic deformation. Often results in "cup-and-cone" fracture surface. Desirable as it provides warning. Brittle Fracture: Little or no plastic deformation. Catastrophic. Can be transgranular (through grains) or intergranular (along grain boundaries). Stress Concentrators: Flaws (e.g., cracks, sharp corners) cause localized stress intensification. $$\sigma_m = 2 \sigma_o \sqrt{\frac{a}{\rho_t}}$$ ($\sigma_m$: stress at crack tip, $\sigma_o$: applied stress, $a$: crack length, $\rho_t$: radius of curvature at crack tip). Griffith Theory: Predicts brittle fracture based on energy balance between strain energy release and surface energy creation. Crack propagates if $\sigma_m$ exceeds critical stress $\sigma_c$. Fracture Toughness ($K_{Ic}$): Material's resistance to brittle fracture when a crack is present. Impact Testing: Measures energy absorption during fracture, used to determine DBTT. Creep Definition: Time-dependent permanent deformation under constant load/stress, typically at high temperatures ($T > 0.4 T_m$). Creep Curve Stages: Primary (Transient) Creep: Decreasing creep rate. Secondary (Steady-State) Creep: Constant creep rate. Most important for design. Tertiary Creep: Increasing creep rate leading to fracture. Creep Mechanisms: Diffusional Creep (Nabarro-Herring, Coble): Mass transport via vacancy diffusion (bulk or grain boundary). Dislocation Creep (Power-Law Creep): Dislocation climb-glide. Creep Failure: Often occurs along grain boundaries, with void formation and growth. Fatigue Definition: Failure under cyclic stresses, occurring at stress levels below yield strength. Accounts for ~90% of metallic structural failures. Necessary Conditions: Cyclic loading, tensile stress at crack tip, plastic deformation. Stages of Fatigue Failure: Crack Initiation (often at surface intrusions/extrusions). Crack Propagation (characterized by striations and beach marks). Final Failure (rapid fracture). Fatigue Testing: S-N Curves (Stress Amplitude vs. Cycles to Failure). Fatigue Limit ($S_{fat}$): Stress below which fatigue will not occur (for some materials like steel). Fatigue Strength: Stress level at which failure occurs for a given number of cycles. Improving Fatigue Life: Impose compressive surface stresses (shot peening, carburizing). Remove stress concentrators (avoid sharp corners). Cumulative Damage (Palmgren-Miner Rule): $\sum \frac{n_i}{N_{fi}} = 1$ (Failure occurs when sum of life fractions for different stress amplitudes equals 1).