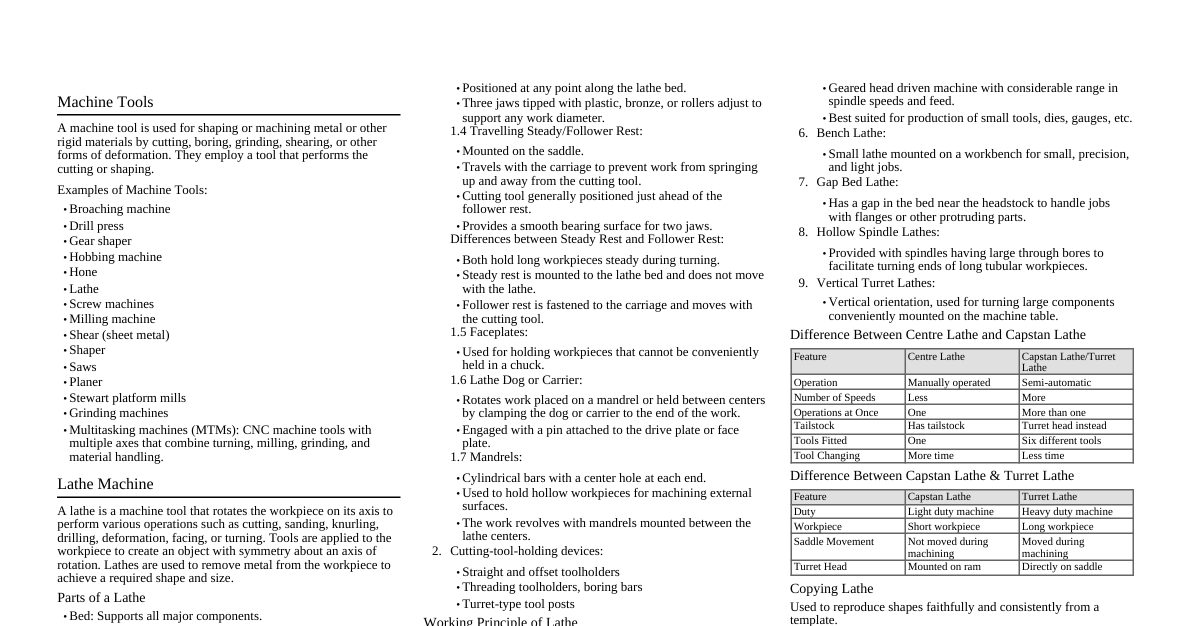

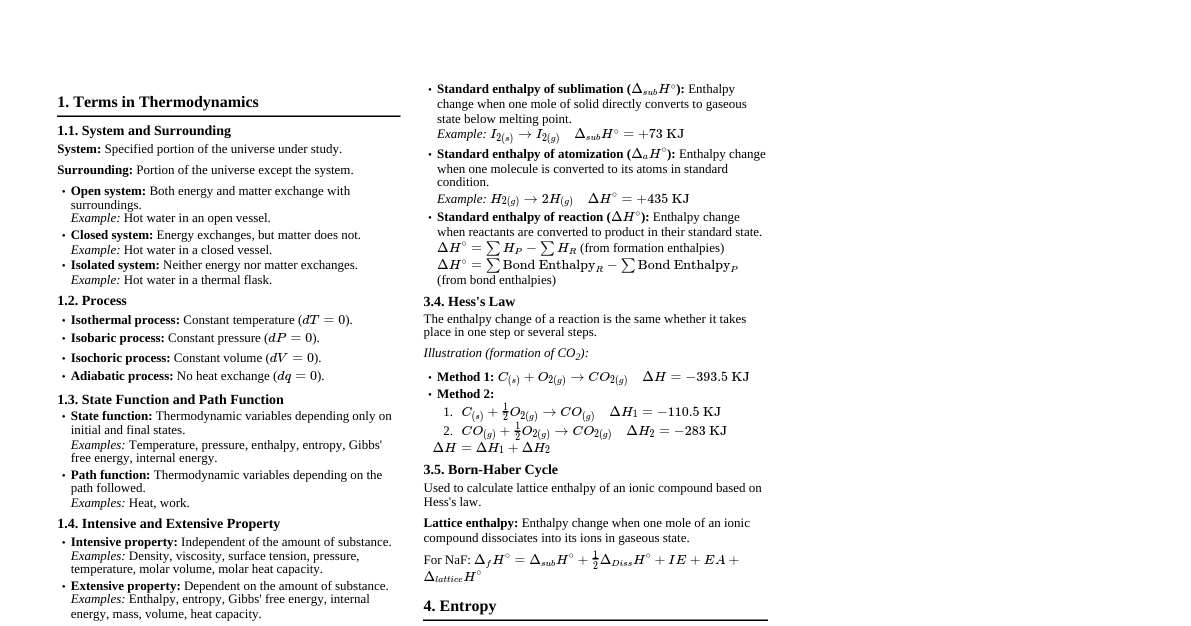

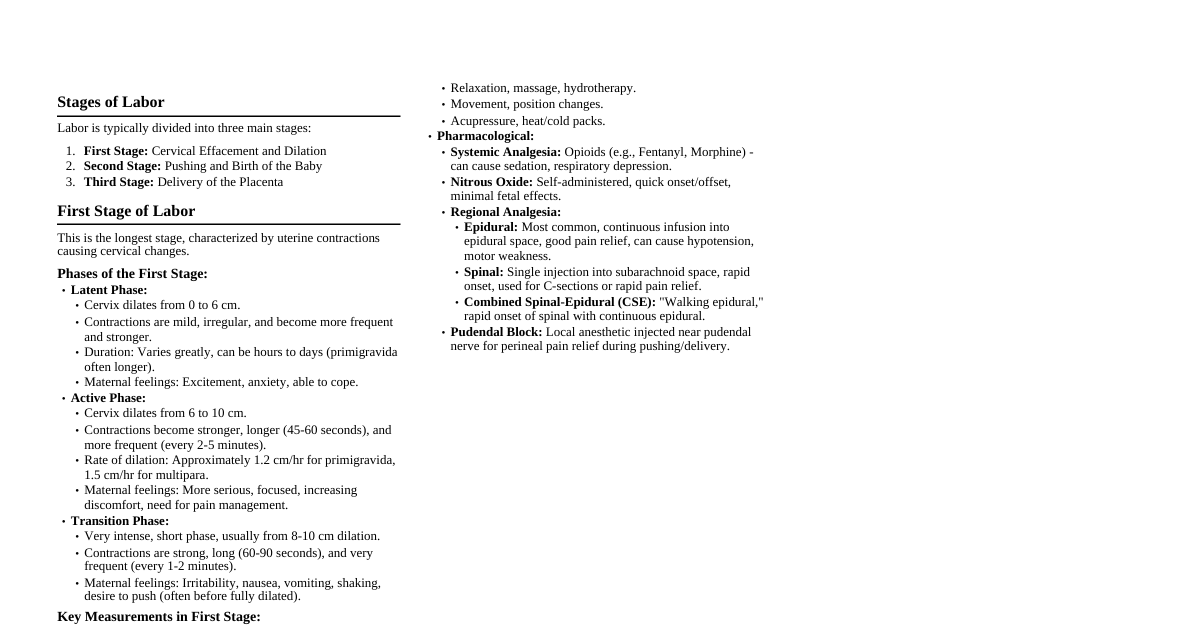

### Machine Tools A machine tool is a machine for shaping or machining metal or other rigid materials, typically by cutting, boring, grinding, shearing, or other forms of deformation. Machine tools employ a specific tool for cutting or shaping. **Examples of Machine Tools:** - Broaching machine - Drill press - Gear shaper - Hobbing machine - Hone - Lathe - Screw machines - Milling machine - Shear (sheet metal) - Shaper - Saws - Planer - Stewart platform mills - Grinding machines - Multitasking machines (MTMs) – CNC machine tools with multiple axes that combine turning, milling, grinding, and material handling for automated production. ### Lathe Machine A lathe is a machine tool that rotates a workpiece on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation, facing, and turning. Tools are applied to the workpiece to create objects with symmetry around an axis of rotation. Lathes are primarily used to remove metal from a workpiece to achieve a required shape and size. #### Block Diagram of Lathe Machine ### Parts of Lathe - **Bed:** Supports all major components. - **Carriage:** Slides along the ways and consists of the cross-slide, tool post, and apron. Used for longitudinal feed. - **Headstock:** Holds the jaws for the workpiece, supplies power to the jaws, and has various drive speeds. - **Tailstock:** Supports the other end of the workpiece. - **Feed Rod and Lead Screw:** The feed rod is powered by gears from the headstock. The lead screw transmits power from the headstock to the carriage for screw thread cutting operations. - The lead screw is used for threading, and the feed rod is used for turning operations. Automatic feed requires engagement of either the feed rod or lead screw. - **Stand (or legs):** Supports the lathe and elevates the bed to a working height. - **Spindle:** A hollow horizontal axle with interior and exterior threads for mounting workpieces. - **Cross-slide:** A flat piece that sits crosswise on the bed, used for cross feed. - **Tool Post:** Sits on top of the cross-slide and holds the cutting tool. - **Tool Rest:** A horizontal area in line with the spindle and tailstock, used to brace hand tools. ### Lathe Accessories Accessories are divided into two categories: #### Work-holding, -supporting, and -driving devices - Lathe centers, chucks, faceplates - Mandrels, steady and follower rests - Lathe dogs, drive plates #### Cutting-tool-holding devices - Straight and offset toolholders - Threading toolholders, boring bars - Turret-type tool posts #### 1. Lathe Centers - Work turned between centers must have a center hole drilled in each end. - Provides support during cutting. - Most common are solid Morse taper shank 60º centers, made of steel with carbide tips. - Require occasional adjustment and lubrication. **Types of Centers:** - **Live Centre (Revolving Centre):** Constructed with its own bearings, fits in the headstock spindle, and rotates with the spindle. - **Dead Centre:** Fits in the tailstock spindle and remains stationary while the work rotates. **Difference between Live Centre and Dead Centre:** A live center fits in the headstock spindle and revolves with the work. A dead center is used in the tailstock spindle and does not revolve with the work. #### 2. Chucks A lathe chuck is mounted on the headstock and can be actuated manually or under power. It holds a rotating workpiece (round, hexagonal, or irregularly shaped). - **Three-jaw Universal Chuck:** - Holds round and hexagonal work. - Grasps work quickly and accurately. - Three jaws move simultaneously when adjusted by a chuck key. - **Four-Jaw Independent Chuck:** - Used to hold round, square, hexagonal, and irregularly shaped workpieces. - Has four jaws, each adjustable independently by a chuck key. - Jaws can be reversed to hold work by inside diameter. **Difference between Universal Chuck and Independent Chuck:** | Feature | Universal Chuck | Independent Chuck | |------------------|---------------------------|--------------------------| | Setup | Easy | Difficult | | Gripping Power | Less gripping power | More gripping power | | Depth of Cut | Comparatively less | Comparatively more | | Job Suitability | Lighter jobs | Heavier jobs can be turned | #### 3. Steady Rest / Fixed Steady - Used to support long work held in a chuck or between lathe centers. - Located on and aligned by the ways of the lathe. - Positioned at any point along the lathe bed. - Three jaws tipped with plastic, bronze, or rollers adjust to support any work diameter within the steady rest capacity. #### 4. Travelling Steady/Follower Rest - Mounted on the saddle. - Travels with the carriage to prevent work from springing up and away from the cutting tool. - The cutting tool is generally positioned just ahead of the follower rest. - Provides a smooth bearing surface for two jaws of the follower rest. **Differences between Steady Rest and Follower Rest:** - Both hold long workpieces steady during turning. - A steady rest is mounted to the lathe bed and does not move with the lathe. - A follower rest is fastened to the carriage and moves with the cutting tool. #### 5. Faceplates - Used for holding workpieces that cannot be conveniently held in a chuck. #### 6. Lathe Dog or Carrier - Rotates work placed on a mandrel or held between centers by clamping the dog or carrier to the end of the work. - Engaged with a pin attached to the drive plate or face plate. #### 7. Mandrels - A cylindrical bar with a center hole at each end. - Used to hold hollow workpieces for machining their external surfaces. - The work revolves with mandrels mounted between the centers of the lathe. ### Working Principle of Lathe - The lathe holds the work between two supports called centers. - A chuck or faceplate is also used for holding the work, mounted on the machine spindle. - The cutting tool is held and supported on a tool post. - The movement of the job is rotation about the spindle axis. - The tool is fed against the revolving work. - The movement of the tool can be parallel to or at an inclination to the work axis. - If the tool moves parallel to the workpiece, a cylindrical surface is formed. - If the tool moves inclined to the axis, it produces a taper surface, known as taper turning. ### Lathe Operations - **Turning:** Produces straight, conical, curved, or grooved workpieces. - **Facing:** Produces a flat surface at the end of the part or makes face grooves. - **Boring:** Enlarges a hole or cylindrical cavity made by a previous process, or produces circular internal grooves. - **Drilling:** Produces a hole by fixing a drill in the tailstock. - **Threading:** Produces external or internal threads. - **Knurling:** Produces a regularly shaped roughness on cylindrical surfaces. - **Chamfering:** An essential operation after thread cutting. ### Summary Table of Lathe | Parts of Lathe Machine | Operations of Lathe Machine | Useable accessories of Lathe machine | Holding Device of Lathe Machine | Some equipment's for catch up as job in Lathe Center | |------------------------|-----------------------------|--------------------------------------|---------------------------------|------------------------------------------------------| | 1) Bed | 1. Turning | 1. Live center | 1. Chuck | 1. Live Center | | 2) Carriage | 2. Threading | 2. Dead Centre | 2. Centers | 2. Dead Center | | 3) Headstock | 3. Facing | 3. Driving Plate | 3. Face plate | 3. Drive plate | | 4) Tailstock | 4. Forming | 4. Face plate | 4. Angle plate | 4. Driving Dog | | 5) Feed rod & Lead screw | 5. Knurling | 5. Steady rest | | | | 6) Spindle | 6. Boring | 6. Follower rest | | | | 7) Cross-slide | 7. Chamfering | 7. Collate chuck | | | | 8) Tool Post | 8. Drilling | 8. Drill holder | | | | 9) Tool Rest | | 9. Coolant equipment | | | ### Classification of Lathe Most lathes used today fall into the following classifications: #### i. Speed Lathe - Characterized by the high speed of its headstock spindle (usually 1200 to 3600 rpm). - Simplest form of lathe, consisting of a headstock, tailstock, and tool-post. - Lacks a gearbox, lead screw, and carriage. - Tools are hand operated. - A cone-pulley is the only source for spindle speed variation. - Applied in wood turning, metal spinning, and polishing operations. #### ii. Engine Lathe or Centre Lathe - The most important and widely used machine tool in the lathe family. - Its name comes from early machine tools being driven by separate engines or a central engine with overhead belts and shafts. - Stepped cone-pulley or geared head mechanisms are often used for varying spindle speed. - Cutting tools can be controlled manually or by power, with feed in both cross and longitudinal directions via a carriage, feed rod, and lead screw. - A wide range of attachments can be fitted to increase its utility. #### iii. Turret Lathe - Used to perform a large number of operations simultaneously. - Several tools are set on a revolving turret to facilitate multiple operations with minimal time wastage. - An indexable square tool post is provided on the cross-slide for mounting turning and parting-off tools. - The turret typically accommodates six tools for operations like drilling, countersinking, reaming, tapping, etc., which can be brought into working position by indexing. - Widely used for repetitive batch production. #### iv. Capstan Lathe - Similar to turret lathes. - In a capstan lathe, the hexagonal turret is carried on a slide mounted in a saddle bolted to the bed. In a turret lathe, the hexagonal turret is mounted directly on a slide on the bed. - Best suited for fast production of small parts due to its light weight and short stroke of the capstan slide. #### v. Tool Room Lathe - A modern engine lathe equipped with all necessary accessories for accurate tool room work. - Geared head driven machine with a considerable range in spindle speeds and feed. - Best suited for the production of small tools, dies, and gauges. #### vi. Bench Lathe - A small lathe that can be mounted on a workbench for small precision and light jobs. #### vii. Gap Bed Lathe - These lathes have a gap in the bed near the headstock to handle jobs with flanges or other protruding parts. #### viii. Hollow Spindle Lathes - Provided with spindles having large through bores to facilitate turning the ends of long tubular workpieces. #### ix. Vertical Turret Lathes - Have a vertical orientation and are used for turning large components that can be conveniently mounted on the machine table. #### Difference between Centre Lathe and Capstan Lathe | Feature | Centre Lathe | Capstan Lathe/Turret Lathe | |---------------------------|---------------------------|----------------------------| | Operation | Manually operated | Semi-automatic | | Number of Speeds | Less | More | | Operations per time | Only one operation | More than one operation | | Tailstock/Turret | Has tailstock | Turret head instead | | Number of Tools | Only one tool | Six different tools | | Tool Changing Time | More | Less | #### Difference between Capstan Lathe & Turret Lathe | Feature | Capstan Lathe | Turret Lathe | |----------------------|---------------------------------|------------------------------------| | Duty | Light duty machine | Heavy duty machine | | Workpiece Length | Short workpiece can be machined | Long workpiece can be machined | | Saddle Movement | Saddle will not be moved | Saddle moved during machining | | Turret Head Mounting | Mounted on ram, ram on saddle | Directly mounted on saddle | #### Copying Lathe Used to reproduce shapes faithfully and consistently from a large or small template. Types include: - Mechanical type - Hydraulic type - Electric type #### Hydraulic Type The hydraulic type copying lathe system is a servo-motor system that magnifies a small input force or signal to provide a large output force or signal for operating the machine. ### Size and Specification of Lathe The size of a lathe is specified in the following ways: 1. Height of the centers measured over the lathe bed. 2. Swing or maximum diameter that can be rotated over the bed ways. 3. Swing or diameter over carriage (largest diameter of work that will revolve over the lathe saddle). 4. Maximum job length (in mm) that may be held between the centers (headstock and tailstock centers). 5. Bed length (in meters), which may include the headstock length. 6. Diameter of the hole through the lathe spindle for turning bar material. Additional specifications necessary when ordering a lathe: i. Length, width, and depth of bed. ii. Depth and width of the gap (if it is a gap lathe). iii. Swing over gap. iv. Number and range of spindle speeds. v. Number of feeds. vi. Lead screw diameter. vii. Number and range of metric threads that can be cut. viii. Tailstock spindle travel. ix. Tailstock spindle set over. x. Back gear ratio. xi. Power rating of the electric motor. ### Milling Machine Milling is a machining process using rotary cutters to remove material by advancing (feeding) the workpiece in a direction at an angle to the tool's axis. It encompasses a wide variety of operations and machines, from small individual parts to large, heavy-duty gang milling. It is one of the most common processes in industry for machining parts to precise sizes and shapes. Milling cutters are rotary cutting tools, often with multiple cutting points. Unlike drilling, where the tool advances along its rotation axis, in milling, the cutter is usually moved perpendicular to its axis. Cutting occurs on the circumference of the cutter. As the milling cutter enters the workpiece, its cutting edges (flutes or teeth) repeatedly cut into and exit the material, shaving off chips through shear deformation. #### Specifications of Milling Machine 1. **Size of the work table:** Expressed in length x width (e.g., 1500 x 30mm). 2. **Longitudinal movement:** Total movement of table in mm (X-direction) (e.g., 800mm). 3. **Transverse movement:** Total movement of saddle along with table in mm (Y-direction) (e.g., 200mm). 4. **Vertical movement:** Total movement of table, saddle & knee in mm (Z-direction) (e.g., 380mm). 5. **Range of the speed:** Speed variation in the gearbox in RPM (e.g., 45 to 200 rpm). 6. **Power capacity of the motor in HP:** (e.g., 2 HP). #### Principal Parts - **Base:** Provides rest for all parts of the milling machine, including the column. Made of gray iron by casting. - **Column:** A rigid vertical box housing the driving mechanism of the spindle. The table and knee are fixed to the column's guide ways. - **Knee:** Can be adjusted vertically on the column. Houses the feed mechanism of the table and other controls. - **Saddle:** Placed on top of the knee. Provides guide ways for the movement of the table. - **Table:** Rests on the saddle, with T-shaped slots for clamping the workpiece. Table movements (feed motions) are controlled by a lead screw. - **Overhanging Arm:** Mounted on the column and serves as a bearing support for the arbor. It is adjustable to provide bearing support near the milling cutter. - **Arbor:** Holds rotating milling cutters rigidly and is mounted on the spindle. A stub arbor is a cantilevered arbor supported at maximum distance from the overhanging arm. Locking provisions ensure reliability. - **Front Brace:** Used to adjust the relative position of the knee and overhanging arm, providing extra support for rigidity. - **Spindle:** Projects from the column face with a tapered hole to accommodate the arbor. Its accuracy, strength, and rigidity determine the milling machine's performance. The spindle transfers motive power to the arbor via belt or gear from the column. ### Types of Milling Machines The varieties of milling machines available are: **I. Knee and Column Type** a. Horizontal b. Vertical c. Universal d. Turret type **II. Production (Bed) type** a. Simplex b. Duplex c. Triplex **III. Plano Millers** **IV. Special type** a. Rotary table b. Drum type c. Copy milling d. Keyway milling machines e. Spline shaft milling machines #### Universal Milling Machine - Named for its ability to perform a large variety of operations. - Distinguishing feature: its table is mounted on a circular swiveling base with degree graduations. - The table can be swiveled to any angle on either side of the normal position. - Helical milling operation is possible as the table can be fed to the cutter at an angle. - Provision of numerous auxiliaries like dividing head, vertical milling attachments, and rotary table make it suitable for a wide range of operations. ### Milling Operations 1. **Angular Milling:** For angular cuts like V-notches & grooves (uses double angle cutter). 2. **Form Milling:** Produces various types of forms (uses form cutter). 3. **Plain Milling/Slab:** Creates flat surfaces on the workpiece (uses plain cutter). 4. **Face Milling:** Produces flat surfaces (uses face milling cutter). 5. **End Milling:** Produces flat surfaces (uses end milling cutter). 6. **Slot Milling:** Produces slots like T-slots, plain slots, etc. 7. **Gang Milling:** Produces many surfaces on a workpiece simultaneously. #### Two Major Classes of Milling Process: - **Face Milling:** - Cutting action primarily occurs at the end corners of the milling cutter. - Used to cut flat surfaces (faces) or flat-bottomed cavities. - Cutter axis is perpendicular to the surface being machined. - **Peripheral Milling:** - Cutting action primarily occurs along the circumference of the cutter. - The cross-section of the milled surface receives the shape of the cutter. - Cutter axis is parallel to the surface being machined, and cutting edges are on the outside periphery of the cutter. ### Indexing Indexing is the method of dividing the periphery of a job into an equal number of divisions. - The operation of rotating the job through a required angle between two successive cuts is called indexing. - Accomplished with a dividing head, an accessory to the milling machine. - Helps divide the job periphery into equal divisions. To rotate a job through a required angle, two components are needed: a. A device to rotate the job (met by an index-crank in the dividing head). b. A source to ensure the job has rotated through the desired angle (met by an index plate). - The index-plate has multiple concentric circles, each with an equally spaced number of holes. - The rotation of the crank is transmitted to the job via a gear. - The ratio of the crank and the shaft on which the job is mounted is **40:1**. This means 40 revolutions of the index crank turn the spindle one full turn. #### Index Plate Types - **Brown and Sharpe type:** Consists of 3 plates, each with 6 circles of drilled holes: - Plate I: 15, 16, 17, 18, 19, 20 holes - Plate II: 21, 23, 27, 29, 31, 33 holes - Plate III: 37, 39, 41, 43, 47, 49 holes - **Cincinnati type:** Consists of one plate drilled on both sides with circles: - First side: 24, 25, 28, 30, 34, 37, 38, 39, 41, 42, 43 holes - Second side: 46, 47, 49, 51, 53, 54, 57, 58, 59, 62, 66 holes #### Simple Indexing or Plain Indexing In simple indexing, an index plate is selected and fitted on the worm shaft, locked via a locking pin. To index, the index crank pin is withdrawn from the hole, and the work is indexed by turning the index crank through a calculated number of whole revolutions and holes on one of the hole circles. The index pin is then relocated. The number of turns the crank must be rotated for each indexing is given by the formula: $$N = \frac{40}{Z}$$ Where: - $N$ = Number of turns of the index crank - $Z$ = Number of divisions or indexing needed on the work - $40$ = Number of teeth on the worm wheel attached to the indexing plate. **Example:** - To mill a gear with 8 equally spaced teeth: $N = 40/8 = 5$ turns of the crank. - To space equally for 10 teeth: $N = 40/10 = 4$ turns of the crank. For example, to index for 16 divisions: $N = 40/16 = 2 \frac{8}{16}$ turns. This means two complete rotations of the crank plus 8 more holes on the 16-hole circle of plate 1 (Plate I - 15, 16, 17, 18, 19, 20 holes). #### Methods of Indexing: 1. Direct Indexing 2. Simple Indexing 3. Compound Indexing 4. Differential Indexing 5. Angular Indexing Method ### Difference between Horizontal and Vertical Milling Machine | Feature | Horizontal Milling Machine | Vertical Milling Machine | |---------------------------|---------------------------------------------|-------------------------------------------| | Spindle Orientation | Horizontal to worktable | Vertical to worktable | | Cutter Movement | Cannot move up and down | Can move up and down | | Spindle Tilt | Cannot be tilted | Can be tilted | | Operations | Plain milling, form milling, gang milling | Slot milling, T-slot milling, angular milling, flat milling | | Cutter Mounting | Mounted on the arbor | Directly mounted on the spindle | #### Difference between Up Milling & Down Milling | Feature | Up Milling (Conventional) | Down Milling (Climb) | |---------------------------|---------------------------------------------|-------------------------------------------| | Workpiece Feed Direction | Opposite to cutter rotation | Same direction as cutter rotation | | Cutting Force Direction | Upwards | Downwards | | Clamping | Strong clamping required | Strong clamping not required | | Chips | Progressively thicker | Progressively thinner | | Surface Finish | Poor | Good | | Material Suitability | Hard material | Soft material | ### Shaper A shaper is a machine tool that produces flat surfaces in horizontal, vertical, or inclined planes, depending on the orientation of the cutting tool. #### Features: - Uses a single-point cutting tool for machining. - Tool is clamped in the tool post mounted on the ram. - The ram reciprocates back and forth; the tool cuts material in the forward stroke, with no cutting during the return stroke. - The job is held rigidly in a vice. #### Principle of Working: - The job is rigidly fixed on the machine table. - A single point cutting tool, held in the tool post, is mounted on a reciprocating ram. - The reciprocating motion of the ram is obtained by a quick return motion mechanism. - As the ram reciprocates, the tool cuts material during its forward stroke. The return stroke is an idle stroke with no cutting action. - The forward and return strokes constitute one operating cycle. - To reduce time wasted during the non-cutting return stroke, shapers are fitted with a quick return mechanism, typically of the crank and slotted-link design. #### Quick Return Mechanism - This mechanism makes the return stroke faster than the cutting stroke. - Converts rotary motion into reciprocating motion. - Reduces idling time. - The shaper machine is a prime example. **Working of Quick Return Mechanism:** The crank AB (adjustable length R) rotates at a uniform angular speed. The crank pin B, shaped like a die block, slides freely inside the slot of the slotted lever OBC. This slotted lever is pivoted at O, and its other end C connects to the ram by a short link arm. When crank AB rotates clockwise from position AB₁ to AB₂, the ram moves forward (left to right). When it rotates from AB₂ to AB₁, the ram returns to its original position. The time for the forward stroke is proportional to angle $\alpha$, and the return stroke is completed in less time, proportional to angle $\beta$. **Why Quick Return Mechanism?** A shaper only cuts during the forward stroke; the backward stroke is idle. To minimize this waste, the return stroke must be completed as quickly as possible. #### Specification of Shaper Machine: 1. Maximum length of stroke of Ram 2. Power input 3. Floor Space required 4. Weight of the machine 5. Cutting to Return Stroke ratio range 6. Feed range 7. Adjustable range (depth) #### Difference between Shaper and Planer Machine: | Feature | Shaper Machine | Planer Machine | |---------------------|--------------------------------|--------------------------------| | Cutting Tool Motion | Reciprocates | Stationary | | Workpiece Motion | Stationary | Reciprocates | | Workpiece Size | Suitable for small workpieces | Suitable for larger workpieces | | Tool Size | Smaller | Larger | | Cut Depth | Only lighter cut can be taken | Only heavier cut can be taken | | Initial Cost | Less | High | | Area Occupied | Smaller work area | Larger work area | ### Other Machining Operations #### Boring Operation In machining, boring is the process of enlarging an already drilled (or cast) hole using a single-point cutting tool (or a boring head with multiple tools), such as in boring a gun barrel or an engine cylinder. #### Broaching Operation Broaching is a machining process that uses a toothed tool called a broach to remove material. There are two main types: linear and rotary. In linear broaching (more common), the broach moves linearly against a workpiece. Broaches are used in a broaching machine. Broaching is used for precision machining, especially for odd shapes (circular and non-circular holes, splines, keyways, flat surfaces). Typical workpieces include small to medium-sized castings, forgings, screw machine parts, and stampings. Although broaches can be expensive, broaching is favored for high-quantity production runs. Broaches are shaped like a saw, but the height of the teeth increases along the tool's length. They have three distinct sections: roughing, semi-finishing, and finishing. Broaching is unusual because the feed is built into the tool, and the machined surface's profile is always the inverse of the broach's profile. #### Sawing Operation Sawing uses a multipoint cutting tool. In this operation, many teeth move through the workpiece, each successive tooth deepening the cut. Feed is given to either the saw or the workpiece. #### Honing Machine Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive stone along a controlled path. It primarily improves the geometric form of a surface and can also improve its texture. Common applications include finishing cylinders for internal combustion engines and air bearing spindles. The hone is usually turned in the bore while moving in and out. Special cutting fluids are used for smooth cutting and to remove abraded material. Machines can be portable, manual, or fully automatic with gauging. #### Hobbing Machine Hobbing is a machining process for cutting gears, splines, and sprockets on a hobbing machine, which is a specialized type of milling machine. The teeth or splines are progressively cut into the workpiece by a series of cuts from a hob (cutting tool). ### Difference among Drilling, Boring and Reaming #### Drilling: - For making cylindrical bore. - Drill bit is used. #### Boring: - For enlarging drilling hole. - Boring bar is used in boring. #### Reaming: - For finishing holes or slightly removing material from the hole. - Reamer is the cutting tool. #### Difference among Counter Boring, Counter Sinking & Counter Drilling: - **Counter Boring:** Used to enlarge one end of an existing hole, concentric with the original hole. - **Counter Sinking:** Used to enlarge the top portion of an existing hole to a conical shape. - **Counter Drilling:** Used to drill in the opposite direction. ### Cutting Tools A cutting tool or cutter is any tool used to remove material from a workpiece to achieve the required size and shape. #### Types of Cutting Tools: 1. Single Point Cutting Tool 2. Double Point Cutting Tool 3. Multi Point Cutting Tool #### Characteristics of Cutting Tools: - Hot hardness - Wear resistance - Toughness - Chemical affinity - Favorable cost - Availability - Low coefficient of friction - Shock resistance #### Difference between Single Point and Multi Point Cutting Tool: | Feature | Single Point Cutting Tool | Multi Point Cutting Tool | |---------------------|---------------------------------------------|-------------------------------------------| | Cutting Edges | One cutting edge | Two or more cutting edges | | Shape | Simple | Complex | | Typical Application | Generally used in lathe machines | Generally used in milling and drilling machines | #### Cutting Tool Material: - Diamond - Tool steel - High speed steel - High carbon steel - Ceramics ### Working and Auxiliary Motion The motion that does not directly participate in forming the required surface is called **Auxiliary motion**. However, this motion is essential for the working motion to fulfill its functions (e.g., clamping and unclamping the workpiece). To define the machining process, there's a relationship between cutting speed and feed rate. **Let:** - **Cutting speed ($V$):** m/min - **Feed rate ($S$):** - mm/rev (for rotary motion like lathe, boring, drilling) - mm/tooth (for M.T.C. milling machine) - mm/stroke (for reciprocating motion in shaping and planning machine) - mm/min (for milling machine) **For Rotary working motion:** $$V = \frac{\pi DN}{1000}$$ Where: - $D$ = diameter in mm - $N$ = revolution per min (rpm) **For Reciprocating motion:** $$V = \frac{L}{(1000 T_c)}$$ Where: - $L$ = length in mm - $T_c$ = time of cutting stroke (min) **Relation between cutting stroke and cutting speed:** $$V = \frac{nL(K+1)}{1000K}$$ Where: - $K = \frac{T_c}{T_i}$ - $T_i$ = Time of idle stroke (min) - $n$ = number of strokes per minute = $\frac{1}{(T_c+T_i)} = \frac{K}{T_c(1+K)}$ **Feed per revolution and feed per stroke** is related to **feed per minute** ($S_m$): $$S_m = S \cdot n$$ Where: - $S_m$ = feed per minute - $S$ = feed per revolution or feed per stroke - $n$ = number of revolutions or strokes per minute **Feed per tooth in multiple cutter** is related to **feed per revolution** ($S$): $$S = S_z \cdot Z$$ Where: - $S_z$ = feed per tooth of the cutter - $Z$ = number of teeth on the cutter The machining time ($T_m$) for any operation can be determined from the expression: $$T_m = \frac{L}{S_m}$$ Where: - $L$ = length of the machined surface - $S_m$ = feed per minute ### Mathematical Problems **Sample Problem 1:** Determine the spindle speed for a high-speed steel drill (12 mm diameter) cutting medium carbon steel at 28 m/min. **Sample Problem 2:** Determine the machining time to drill a hole of 20 mm diameter in a work 25 mm thick by a drill at a cutting speed of 30 m/min with a feed of 0.2 mm/rev. **Sample Problem 3:** A 30 mm H.S.S. drill is used to drill a hole in a cast iron block 100 mm thick. Determine the time required to drill the hole if the feed is 0.30 mm/rev. Assume an overtravel of drill as 4 mm. The cutting speed is 20 m/min. **Sample Problem 4:** A 600mm × 30mm flat surface of a plate is to be finish machined on a shaper. The plate has been fixed with the 600mm side along the tool travel direction. If the tool over-travel at each end of the plate is 20mm, the average cutting speed is 8m/min, feed rate is 0.3mm/stroke, and the ratio of return time to cutting time of the tool is 1:2. Determine the time required for machining. **Sample Problem 5:** Bars of 250mm length and 25mm diameter are to be turned on a lathe with a feed of 0.2mm/rev. Each regrinding of the tool costs Rs. 20. The time required for each tool change is 1 min. The tool life equation is given as $VT^{0.2}=24$ (where cutting speed V is in m/min and tool life T is in min). Determine the optimum tool cost per piece for maximum production rate. **Sample Problem 6:** A workpiece of 2000mm length and 300mm width was machined by a planning operation with the feed set at 0.3mm/stroke. If the machine tool executes 10 double strokes/min, determine the planning time for a single pass. **Sample Problem 7:** A 31.8 mm HSS drill is used to drill a hole in a cast iron block 100 mm thick at a cutting speed of 20 m/min and feed 0.3 mm/rev. If the overtravel of drill is 4 mm and approach is 9 mm, determine the time required to drill the hole.