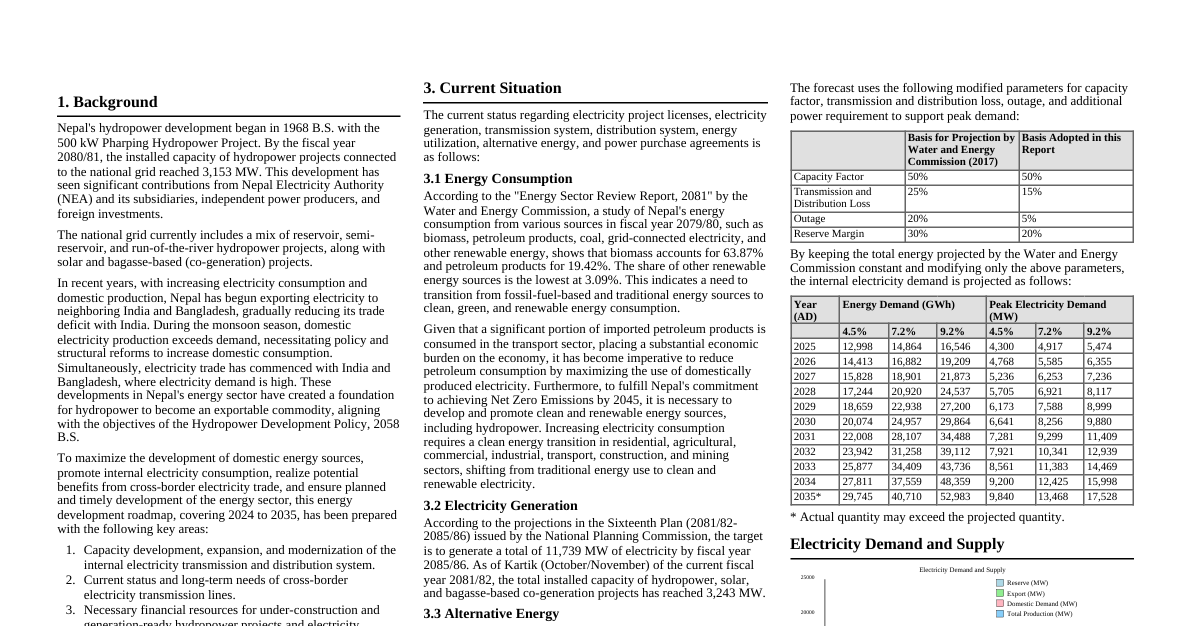

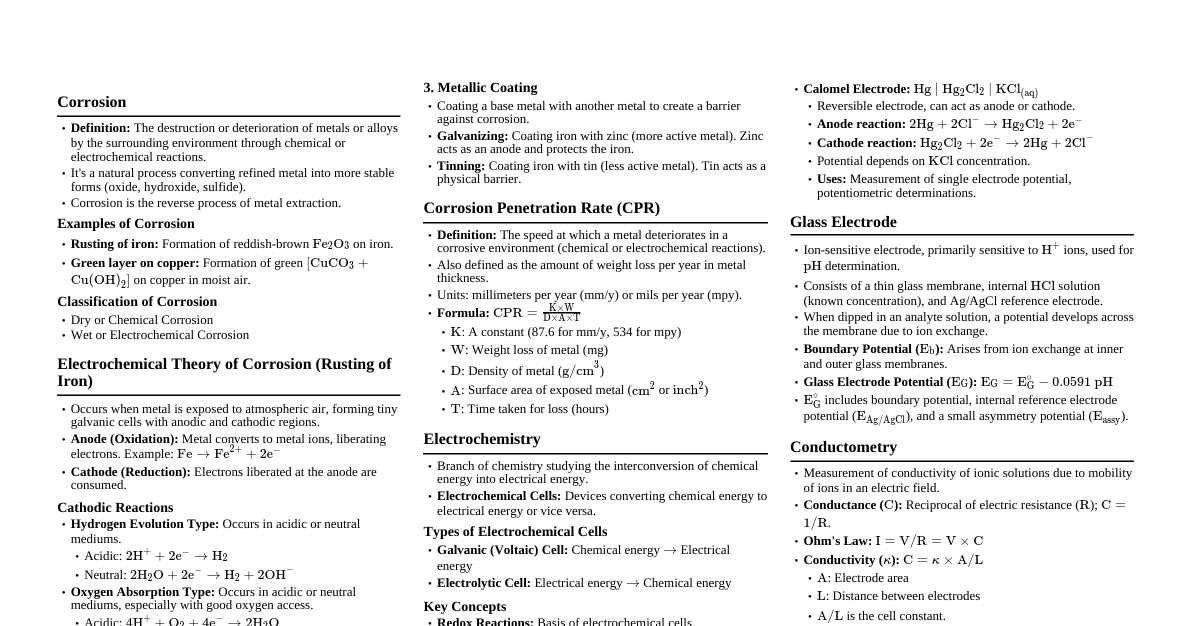

1. Materials for Energy Devices Semiconductors Definition: Materials with conductivity between conductors and insulators. Types: Organic Semiconductors: Carbon-based molecules/polymers, overlap of $\pi$-orbitals, electron delocalization and hopping. Inorganic Semiconductors: Non-carbon-based (e.g., Si, Ge), crystalline structures, strong covalent bonds. p-type Semiconductors: Conduction mainly due to holes (positive charge carriers) from electron deficiency. Pentacene: Properties: Hole-dominated conduction (mobility up to $\sim1$ cm$^2$/V$\cdot$s), HOMO $\sim -5.0$ eV, LUMO $\sim -3.0$ eV (band gap $\sim 2.2$ eV), planar conjugated molecule (strong $\pi-\pi$ stacking), strong visible absorption (Frenkel-type excitons), sensitive to oxygen/moisture/light. Applications: Organic field-effect transistors (OFET), flexible electronics, organic semiconducting chips. n-type Semiconductors: Conduction mainly due to electrons; often formed by doping or using compounds with low LUMO levels. Perfluoropentacene (PFP): N-type organic semiconductor derived from pentacene by fluorination. Properties: High electron affinity, strong $\pi-\pi$ stacking, electron mobility up to $0.11$ cm$^2$/V$\cdot$s. Applications: OFETs (n-type & ambipolar), complementary circuits (high-voltage gain), non-volatile memory devices. Organic Photovoltaics (OPV) / PV Cell Advantages: Low-cost fabrication (solution processing, low temperature), flexible, lightweight, high absorption coefficients (thin films). Principle: Convert solar illumination to photocurrent in 4 steps: Photon absorption $\rightarrow$ exciton generation. Exciton diffusion to donor-acceptor interface. Charge transfer (electron to acceptor, hole to donor). Charge collection at electrodes. P3HT (donor) & PCBM (acceptor): Construction: Anode: Semitransparent Indium Tin Oxide (ITO) for light passage and hole collection. Hole Transport Layer: PEDOT:PSS coated on ITO, prevents electrons reaching anode. Active Layer: P3HT-PCBM blend (e.g., 1:1 ratio in chlorobenzene), P3HT is p-type donor, PCBM is n-type acceptor. Cathode: Aluminum (or Ag, Ca) to collect electrons. Working: Photoexcitation forms excitons (bound electron-hole pairs). Excitons dissociate at D-A interface due to LUMO energy offset (downhill slope for electron movement). Efficient dissociation requires exciton to reach D-A interface before energy loss. Separated electron to acceptor $\rightarrow$ cathode; hole in donor $\rightarrow$ anode. Applications: Flexible/transparent devices, smart windows, hybrid photovoltaics, wearable technology, portable/off-grid solutions. Energy Storage Devices: Battery Definition: Combination of cells (series/parallel) for desired output voltage. Components: Anode: Negative electrode, oxidation occurs. Cathode: Positive electrode, reduction occurs. Electrolyte: Medium for ion transfer. Separator: Separates anode/cathode, ionically conductive, electrically insulating. Classification: Primary Battery: Irreversible, electro-inactive material cannot be converted back (e.g., dry cell, Li-MnO$_2$). Secondary Battery: Reversible, electro-inactive material can be converted back (e.g., Li-ion, Ni-MH). Reserve Battery: Key components (e.g., electrolyte) isolated until usage, high shelf life (e.g., Mg | saline water | AgCl, Ag). Characteristics: Capacity (Ah): Amount of current generated per unit time. $Capacity = \frac{w \cdot n \cdot F}{M}$ (w=weight, n=electrons, F=Faraday, M=molecular weight). Power Density (W/kg or W/L): Ratio of power available to mass/volume, for rapid power delivery. Cycle Life: Number of charge-discharge cycles before failure (for secondary batteries). Affected by chemical changes, current, temperature. Shelf Life: Storage period retaining performance. Affected by self-discharge, temperature. Lithium-Ion Battery (LIB) Working Principle: "Intercalation" - Li-ions insert into/extract from host electrode lattice without changing crystal structure. Components: Anode: Intercalated graphite rod, copper foil current collector. Cathode: Lithium Cobalt Oxide, aluminum foil current collector. Separator: Fine porous polymer film. Electrolyte: Lithium salt (e.g., LiPF$_6$) in organic solvent (e.g., ethylene carbonate). Charging: Li-ions from cathode $\rightarrow$ anode, insert into graphite. Electrons via external path to anode. Anode: $LiCoO_2 \rightarrow xLi^+ + Li_{1-x}CoO_2 + xe^-$ Cathode: $xLi^+ + xe^- + xC_6 \rightarrow xLiC_6$ Overall: $LiCoO_2 + xC_6 \rightarrow Li_{1-x}CoO_2 + xLiC_6$ Discharging: Li-ions from anode $\rightarrow$ cathode. Anode: $xLiC_6 \rightarrow xLi^+ + xe^- + xC_6$ Cathode: $xLi^+ + Li_{1-x}CoO_2 + xe^- \rightarrow LiCoO_2$ Overall: $Li_{1-x}CoO_2 + xC_6 \rightarrow LiCoO_2 + xC_6$ Applications: Mobile phones, laptops, EVs, renewable energy storage, defense. Ultra-Small Asymmetric Supercapacitor Definition: Electrochemical energy storage device storing energy by separating ions at electrode-electrolyte interface. Types: Electrical Double-Layer Capacitors (EDLCs), Pseudocapacitors, Hybrid Capacitors. Construction: Two distinct electrode materials: one for electrostatic storage (e.g., activated carbon), one for faradaic reactions (e.g., metal oxides). Separator between electrodes. Electrolyte solution. Current collectors (metal foils). Compact, miniaturized size. Working (Charging): Positive electrode: $MnO_2 + Na^+ + e^- \rightarrow MnO_2Na$ Negative electrode: $C + Na^+ + e^- \rightarrow C||Na^+$ Overall: $2MnO_2 + C + 2Na^+ + 2e^- \rightarrow 2MnO_2Na + C||Na^+$ Working (Discharging): Positive electrode: $MnO_2Na \rightarrow MnO_2 + Na^+ + e^-$ Negative electrode: $C||Na^+ \rightarrow C + Na^+ + e^-$ Overall: $2MnO_2Na + C||Na^+ \rightarrow 2MnO_2 + C + 2Na^+ + 2e^-$ Applications: IoT sensors, wearable electronics, remote monitoring, implantable devices. MEMS-Based Energy Harvesters Definition: Miniaturized devices integrating mechanical elements, sensors, actuators, and electronics on a chip. Convert ambient energy (mechanical, thermal, EM) into electrical. 1. Piezoelectric Principle: Working: Mechanical stress on piezoelectric material shifts charge centers, producing voltage. Normally, charges are balanced. Stress (stretch/compress) unbalances dipoles, creating net positive/negative charges on opposite faces. 2. Electrostatic Principle: Working: Exploit variable capacitance between two micro-scale conductive plates. Ambient mechanical energy $\rightarrow$ movement of MEMS plate $\rightarrow$ change in capacitance $(C = \epsilon A/d)$ $\rightarrow$ electrical energy generation. 3. Electromagnetic Principle: Working: Based on Faraday's law of electromagnetic induction. MEMS energy harvester: stationary permanent magnet + coil on movable proof mass. Ambient mechanical energy (vibrations) oscillates proof mass, moving coil through magnetic field. Change in magnetic flux induces voltage. Applications: IoT devices, wearable electronics, remote/inaccessible locations, implantable medical devices. 2. Corrosion Science & E-waste Management Corrosion Chemistry Definition: Destruction/deterioration of metals/alloys by chemical/electrochemical reactions with surroundings. A natural process converting refined metal to a more stable form. Electrochemical Theory of Corrosion (Iron Example): Metals form galvanic cells (anodic & cathodic regions). Anode: Metal oxidation ($M \rightarrow M^{n+} + ne^-$), metal loss. Cathode: Reduction (e.g., hydrogen liberation or oxygen absorption). Hydrogen Liberation: Acidic: $2H^+ + 2e^- \rightarrow H_2 \uparrow$ Basic/Neutral: $2H_2O + 2e^- \rightarrow H_2 \uparrow + 2OH^-$ Oxygen Absorption: Acidic: $2H^+ + \frac{1}{2}O_2 + 2e^- \rightarrow H_2O$ Basic/Neutral: $H_2O + \frac{1}{2}O_2 + 2e^- \rightarrow 2OH^-$ Iron Corrosion: $Fe^{2+} + 2OH^- \rightarrow Fe(OH)_2$. Then $3Fe(OH)_2 + \frac{1}{2}O_2 \rightarrow Fe_3O_4 \cdot 3H_2O$. Types of Corrosion 1. Galvanic Corrosion (Differential Metal Corrosion): Occurs when two dissimilar metals are in contact in a corrosive medium. Metal with lower Standard Reduction Potential (SRP) acts as anode and corrodes. Example: Iron (-0.44V) and Copper (+0.34V) in contact, iron corrodes. Factors: Potential difference, ratio of anodic to cathodic area, environment, passivity. 2. Differential Aeration Corrosion: Occurs when same metal is exposed to two different oxygen concentrations. Less aerated part acts as anode and corrodes; more aerated part acts as cathode. Water Line Corrosion: Occurs just below the water line (less aerated, anode) on partially immersed metals. Pitting Corrosion: Localized, intense corrosion due to small anodic areas (e.g., under dust particles) and large cathodic areas (surrounding metal). Corrosion Control I) Metallic Coating: Barrier between base metal and corrosive environment. Galvanization: Coating iron with zinc (Zn) by hot dipping. Zn acts as sacrificial anode. Process: Clean surface, dip in molten zinc ($425-430^\circ C$), remove excess. Applications: Roofing sheets, fencing wire, buckets, pipes. II) Inorganic Coatings: Convert metal surface to inorganic compound (oxide/phosphate). Anodizing of Al: Oxidation of outer layer of Al to $Al_2O_3$ by electrolysis. Process: Clean Al, connect as anode, use chromic acid electrolyte, Pb cathode, apply voltage. $2Al + 3H_2O \rightarrow Al_2O_3 + 3H_2$. Sealing: Dip in boiling water to hydrate $Al_2O_3$ to $Al_2O_3 \cdot H_2O$, reducing porosity. III) Cathodic Protection: Protect metal by forcing it to act as cathode. Sacrificial Anode Method: Connect more active metal (e.g., Zn, Mg) to the metal to be protected. Active metal corrodes preferentially. Impressed Current Method: Connect metal to be protected to negative terminal of DC source (becomes cathode). Inert electrode (e.g., graphite) as anode. Corrosion Penetration Rate (CPR) Definition: Speed at which metal/alloy deteriorates in corrosive environment (weight loss per year or thickness reduction). Formula: $CPR = \frac{K \cdot W}{D \cdot A \cdot T}$ $K$: constant (534 for mpy, 87.6 for mmpy) $W$: weight loss $D$: density $A$: surface area $T$: exposure time Weight Loss Method: Measure mass loss of specimen after exposure to corrosive environment. E-waste (Electronic Waste) Definition: Discarded electrical/electronic equipment. Sources: Large household appliances, IT/telecom equipment, consumer equipment, lighting, tools, toys, medical devices, monitoring instruments. Composition & Characteristics: Contains valuable (Cu, Au, Ag, Al) and toxic (As, Cd, Cr, Pb, Hg) materials. Plastics, glass, circuit boards, batteries, flame retardants, PCBs. Need for Management: Decreases environmental/health issues, conserves raw materials, energy efficient, reduces greenhouse gas emissions, social benefits. Health Hazards: Lead: Damages CNS, blood, kidneys, child brain development. Cadmium: Accumulates in kidneys/liver, chronic brain damage, irreversible toxic effects. Mercury: Respiratory/skin disorders, bioaccumulation in fish. Chromium: Bronchitis. Barium: Muscle weakness, heart/liver/spleen damage. Copper: Stomach cramps, nausea, liver damage. Nickel: Skin allergy (dermatitis), lung allergy (asthma). Lithium: Passes into breast milk, harms nursing babies. Beryllium: Carcinogenic (lung cancer), chronic beryllium disease. Plastics/PVC: Dioxin production when burned (reproductive/developmental problems). Brominated Flame Retardants: Disrupt endocrine system. Extraction of Gold from E-waste (Bioleaching Method) Principle: Dissolving metals using microorganisms (bacteria/fungi) in acidic/oxidizing conditions. Steps: Collection & Pretreatment: Shredding, removal of non-metal parts. Preparation of Leaching Medium: Grow microorganisms (e.g., A.ferrooxidans , A.thiooxidans ) in nutrient medium (Fe$^{2+}$ or S$^0$), maintain acidic pH ($\sim2.0$), temperature ($30-37^\circ C$), aeration. Bioleaching Reaction: Microorganisms oxidize metals to soluble ions. A.ferrooxidans : $2Fe^{2+} + 0.5O_2 + 2H^+ \rightarrow 2Fe^{3+} + H_2O$. $Fe^{3+}$ is strong oxidizing agent. A.thiooxidans : $S^0 + 1.5O_2 + H_2O \rightarrow H_2SO_4$. Sulfuric acid dissolves base metals. Dissociation of Base Metals: Base metals like copper are dissolved. $Cu + 2Fe^{3+} \rightarrow Cu^{2+} + 2Fe^{2+}$ Gold Solubilization: Bacterium Chromobacterium violaceum produces natural cyanide (CN$^-$), forming a complex with gold. $4Au + 8CN^- + O_2 + 2H_2O \rightarrow 4[Au(CN)_2]^- + 4OH^-$. Recovery of Gold from Solution: Cementation: Reduce with Zn dust. $2[Au(CN)_2]^- + Zn \rightarrow 2Au + [Zn(CN)_4]^{2-}$ Electrodeposition: Pass electric current in an electrolytic cell.