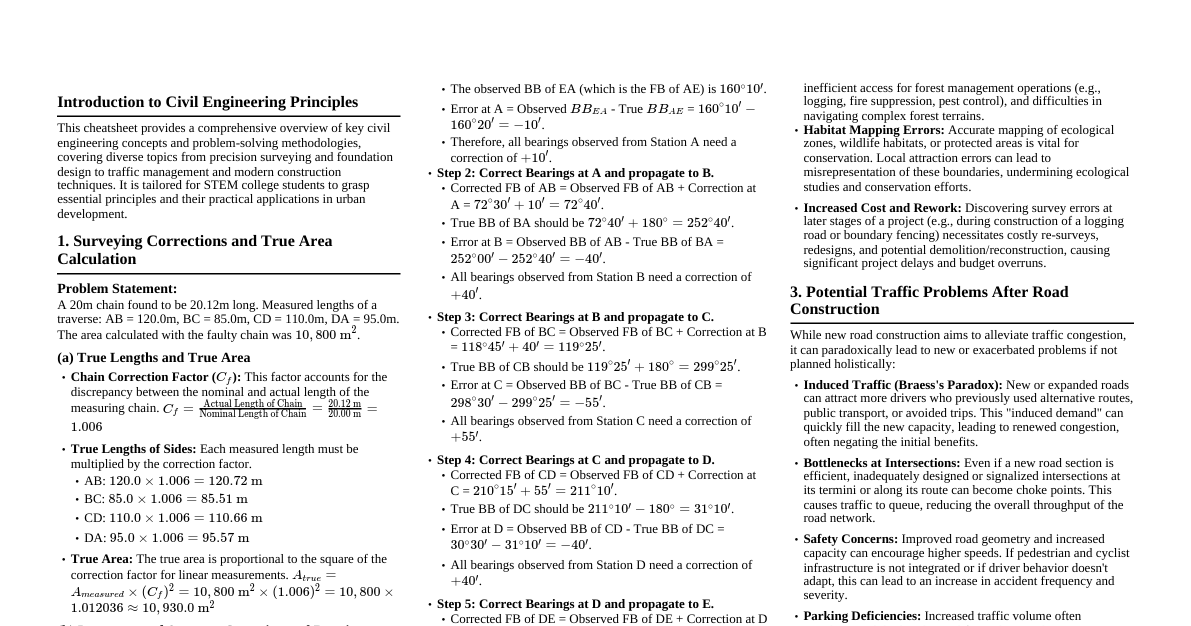

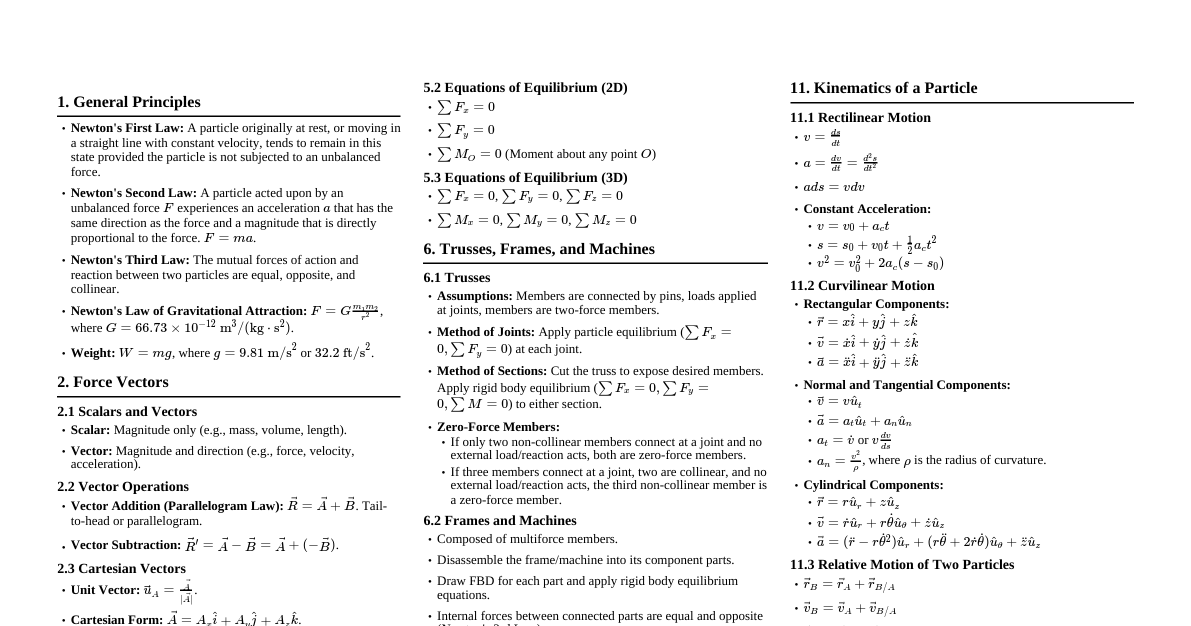

Module 1: Introduction to Engineering Materials 1.1 Cements & Concrete Cements: Binders that set and harden to form a solid mass. Main types: Portland cement. M-Sand: Manufactured sand, an alternative to river sand, produced by crushing rocks. Concrete: Composite material made of cement, aggregates (fine & coarse), and water. Plain Concrete (PCC): Basic concrete, good in compression, weak in tension. Reinforced Concrete (RCC): PCC with steel reinforcement to resist tensile forces. Fibre-Reinforced Concrete: Includes steel, glass, or polymer fibers to improve tensile strength, ductility, and crack resistance. Lightweight Concrete: Uses lightweight aggregates (e.g., pumice, expanded shale) to reduce density. High Performance Concrete (HPC): Enhanced strength, durability, and workability, low permeability. Polymer Concrete: Uses polymer resin as a binder instead of cement. Fast curing, high strength, chemical resistance. 1.2 Ceramics & Refractories Ceramics: Inorganic, non-metallic solids processed at high temperatures. Hard, brittle, high melting points, electrical insulators. Uses: Tiles, bricks, electrical insulators, cutting tools. Refractories: Ceramics designed to withstand high temperatures without softening or deforming. Uses: Furnace linings, kilns, incinerators. 1.3 Bitumen & Asphaltic Materials Bitumen: Viscous, black, sticky, organic liquid, a byproduct of petroleum distillation. Properties: Waterproof, adhesive, thermoplastic. Uses: Road paving, roofing, waterproofing. Asphaltic Materials: Mixtures of bitumen and mineral aggregates. 1.4 Timbers, Glass & Plastics Timbers: Natural organic material from trees. Strong in tension along grain, good strength-to-weight ratio. Properties: Anisotropic, combustible, susceptible to decay. Uses: Construction, furniture, paper. Glass: Amorphous solid, typically made from silica. Transparent, brittle, chemical resistant. Uses: Windows, containers, fiber optics. Plastics: Synthetic organic polymers. Lightweight, versatile, corrosion resistant. Types: Thermoplastics (can be remolded), Thermosets (cannot be remolded). Uses: Packaging, pipes, insulation, automotive parts. 1.5 Structural Steel & Other Metals Structural Steel: Iron alloy with low carbon content ($ Uses: Building frames, bridges, machinery. Other Metals: Aluminum (lightweight, corrosion resistant), Copper (electrical conductivity), Titanium (high strength-to-weight, corrosion resistant). 1.6 Paints & Varnishes Paints: Pigmented liquid applied to surfaces to protect, color, or provide texture. Components: Pigment, binder, solvent, additives. Varnishes: Transparent protective coatings with no pigment. 1.7 Acoustical Materials & Geotextiles Acoustical Materials: Absorb or block sound. Examples: Mineral wool, foam panels. Geotextiles: Permeable fabrics used in civil engineering applications. Uses: Soil separation, filtration, reinforcement, drainage. 1.8 Rubber, Asbestos, Laminates & Adhesives Rubber: Elastomeric polymer. Elastic, waterproof, electrical insulator. Types: Natural, Synthetic. Asbestos: Natural fibrous silicate mineral. Heat resistant, fireproof (now largely banned due to health risks). Laminates: Materials made by bonding multiple layers together (e.g., plywood, high-pressure laminates). Adhesives: Substances that bond materials together by surface attachment. 1.9 Advanced Materials Graphene: 2D material, single layer of carbon atoms. Extremely strong, conductive. Carbon Composites: Carbon fibers embedded in a polymer matrix. High strength-to-weight ratio, stiff. Module 2: Introduction to Material Testing 2.1 What is Material Engineering? Study of materials' properties and applications, and their processing and performance. Focuses on the relationship between structure, properties, processing, and performance. 2.2 Mechanical Behavior & Characteristics Describes how materials respond to applied forces (stress, strain). Key characteristics: Strength, stiffness, ductility, hardness, toughness. 2.3 Elasticity Principle & Characteristics Elasticity: Ability of a material to return to its original shape after deformation when the load is removed. Hooke's Law: Stress is proportional to strain ($\sigma = E \epsilon$) within the elastic limit. Young's Modulus ($E$): Measure of stiffness. 2.4 Plastic Deformation of Metals Permanent deformation that occurs when stress exceeds the yield strength. Caused by dislocation movement (slip) in crystalline materials. 2.5 Tensile Test Standard test to determine mechanical properties under uniaxial tension. Stress-Strain Curve: Elastic Region: Linear, reversible deformation. Yield Strength ($\sigma_y$): Stress at which plastic deformation begins. Ultimate Tensile Strength (UTS): Maximum stress a material can withstand. Fracture Strength: Stress at which the material breaks. Ductility: Measured by elongation and reduction in area. True Stress-Strain: Based on instantaneous cross-sectional area, better represents material behavior after necking. $\sigma_T = P / A_i$ $\epsilon_T = \ln(L_i / L_0)$ Tensile Test Standards: ASTM E8 (metals), ASTM D638 (plastics), etc. Differ for brittle, quasi-brittle, elastic materials. 2.6 Hardness Tests Resistance to localized plastic deformation (indentation). Brinell: Indents with a hardened steel ball. Rockwell: Indents with a diamond cone or steel ball, measures depth of penetration. Vickers: Indents with a diamond pyramid, suitable for wide range of materials. Knoop: Microhardness test for small or brittle samples. 2.7 Bending & Torsion Test Bending Test: Measures flexural strength and modulus for brittle materials (e.g., ceramics, composites). Torsion Test: Measures shear strength and modulus by applying a twisting force. 2.8 Strength of Ceramics High compressive strength, but very low tensile strength due to crack sensitivity. Brittle fracture behavior. 2.9 Internal Friction, Creep & Brittle Fracture Internal Friction: Energy dissipation within a material due to anelastic deformation. Creep: Time-dependent plastic deformation under constant stress at elevated temperatures. Stages: Primary (decreasing rate), Secondary (constant rate), Tertiary (increasing rate to rupture). Brittle Fracture of Steel: Occurs rapidly with little plastic deformation. Ductile-to-Brittle Transition Temperature (DBTT): Temperature range where steel changes from ductile to brittle fracture behavior. 2.10 Fracture Mechanics Study of crack initiation and propagation in materials. Stress Concentration: Stress intensifies at crack tips. Fracture Toughness ($K_{Ic}$): Material's resistance to brittle fracture when a crack is present. Testing: ASTM E399, E1820 (for different materials and conditions). 2.11 Fatigue of Materials Failure under cyclic or fluctuating stresses, often below the yield strength. Fatigue Limit (Endurance Limit): Stress amplitude below which a material can withstand an infinite number of cycles (for some materials like steel). S-N Curve: Stress amplitude vs. number of cycles to failure. 2.12 Structural Integrity Assessment (FIA) Framework to ensure structures are safe and reliable, considering defects, loads, and material properties. Involves fracture mechanics principles to assess remaining life or critical defect size. Module 3: Standard Testing & Evaluation Procedures 3.1 Laboratory for Mechanical Testing Equipped with Universal Testing Machines (UTM), hardness testers, impact testers, fatigue testers, creep testers. Controlled environment to ensure accurate and repeatable results. 3.2 Discussion about Mechanical Testing Importance of standardized procedures (ASTM, ISO) for comparability and reliability. Consideration of specimen preparation, loading rates, temperature, and environmental factors. 3.3 Naming Systems for Irons, Steels & Nonferrous Metals Unified Numbering System (UNS): Standard system for metals and alloys. AISI/SAE: Common for steels (e.g., 1040 carbon steel, 4140 alloy steel). ASTM: Specifies standards for various material forms and grades. 3.4 Discussion about Elastic Deformation Reversible deformation. Governed by atomic bond stretching. Modulus of Elasticity ($E$) is a fundamental material property. 3.5 Plastic Deformation Permanent deformation. Governed by dislocation motion (slip and twinning). Influenced by crystal structure, temperature, strain rate, and microstructure. 3.6 Impact Test & Transition Temperatures Measures the energy absorbed by a material during fracture under high strain rate. Charpy/Izod Test: Standard tests using a pendulum impactor. Ductile-to-Brittle Transition Temperature (DBTT): Critical for materials used in low-temperature applications. 3.7 Fracture Mechanics Background & Toughness Linear Elastic Fracture Mechanics (LEFM): Applies to brittle materials where plastic zone at crack tip is small. Elastic-Plastic Fracture Mechanics (EPFM): For materials with significant plastic deformation at crack tip. Fracture Toughness ($K_{Ic}, J_{Ic}, CTOD$): Measures resistance to crack propagation. Varies significantly between materials (e.g., metals vs. ceramics). 3.8 Fatigue of Material Characterized by crack initiation and propagation under cyclic loading. Factors affecting fatigue life: stress range, mean stress, surface finish, environment, microstructure. Fatigue crack growth rates are measured using Paris Law: $da/dN = A(\Delta K)^m$. 3.9 Creep Testing involves applying a constant load at elevated temperatures and monitoring strain over time. Important for design of components operating at high temperatures (e.g., turbine blades, pressure vessels). Creep rupture strength is a key design parameter.