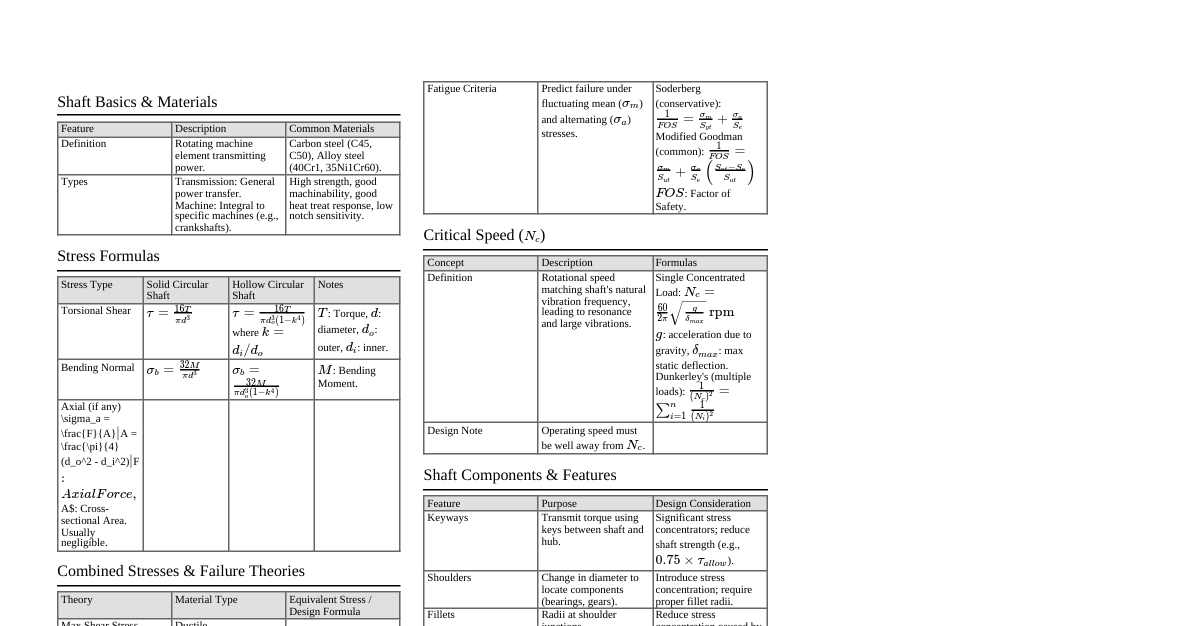

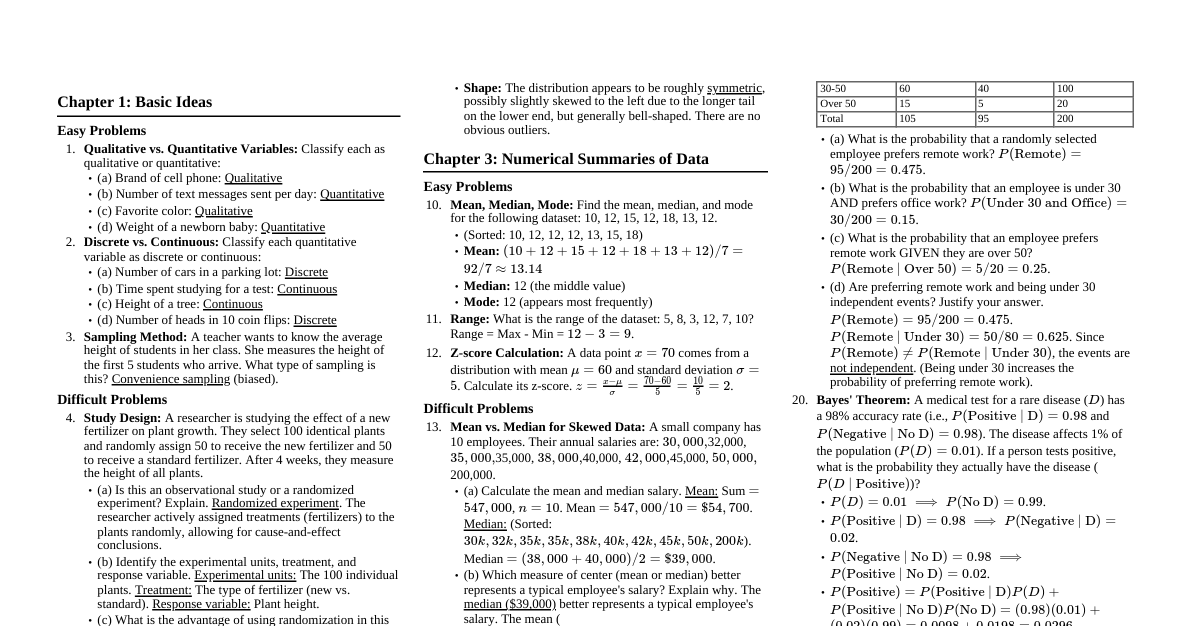

### Stress Formulas | Name of Formula | LaTeX Equation (2-Line Format) | Parameter Definitions & Units | Essential Constants & Reference Values | Summary of Geometric and Material Constants: (Geometric Calculation Constants, Material Reference Constants) | |---|---|---|---|---| | Axial Stress | $$\sigma_t = \frac{P}{A}$$ | $\sigma_t$: Axial Stress (Pa, psi) $P$: Axial Load (N, lbf) $A$: Cross-sectional Area (m$^2$, in$^2$) | None | Geometric: Cross-sectional Area ($A$) - calculated from component dimensions. | | Shear Stress | $$\tau_s = \frac{F}{A}$$ | $\tau_s$: Shear Stress (Pa, psi) $F$: Shear Force (N, lbf) $A$: Cross-sectional Area (m$^2$, in$^2$) | None | Geometric: Cross-sectional Area ($A$) - calculated from component dimensions. | | Torsion | $$\tau_s = \frac{T r}{J} = \frac{16T}{\pi D^3}$$ $$\tau_s = \frac{16TD}{\pi(D^4-d^4)}$$ | $\tau_s$: Shear Stress due to Torsion (Pa, psi) $T$: Torque (N·m, lbf·in) $r$: Radius (m, in) $J$: Polar Moment of Inertia (m$^4$, in$^4$) $D$: Outer Diameter (m, in) $d$: Inner Diameter (m, in) | For solid circular shaft: $J = \frac{\pi D^4}{32}$ For hollow circular shaft: $J = \frac{\pi (D^4-d^4)}{32}$ | Geometric: $D$, $d$ - shaft dimensions. | | Bearing Stress | $$\sigma_b = \frac{F}{A_b}$$ | $\sigma_b$: Bearing Stress (Pa, psi) $F$: Applied Force (N, lbf) $A_b$: Bearing Area (m$^2$, in$^2$) | None | Geometric: Bearing Area ($A_b$) - contact area. | | Bending Stress | $$\sigma_f = \frac{M c}{I} = \frac{6M}{bh^2}$$ | $\sigma_f$: Bending Stress (Pa, psi) $M$: Bending Moment (N·m, lbf·in) $c$: Distance from Neutral Axis to Outer Fiber (m, in) $I$: Area Moment of Inertia (m$^4$, in$^4$) $b$: Width of beam (m, in) $h$: Height of beam (m, in) | For rectangular cross-section: $I = \frac{bh^3}{12}$ | Geometric: $b$, $h$ - beam dimensions. | | Bending Stress (Circular) | $$\sigma_f = \frac{32M}{\pi D^3}$$ $$\sigma_f = \frac{32MD}{\pi(D^4-d^4)}$$ | $\sigma_f$: Bending Stress (Pa, psi) $M$: Bending Moment (N·m, lbf·in) $D$: Outer Diameter (m, in) $d$: Inner Diameter (m, in) | For solid circular shaft: $I = \frac{\pi D^4}{64}$ For hollow circular shaft: $I = \frac{\pi (D^4-d^4)}{64}$ | Geometric: $D$, $d$ - shaft dimensions. | | Thermal Stress | $$\sigma_T = E \alpha (t_2 - t_1)$$ | $\sigma_T$: Thermal Stress (Pa, psi) $E$: Modulus of Elasticity (Pa, psi) $\alpha$: Coefficient of Thermal Expansion (1/°C, 1/°F) $t_2$: Final Temperature (°C, °F) $t_1$: Initial Temperature (°C, °F) | Material: $E$, $\alpha$ - specific to material. | Material: $E$, $\alpha$. | | Thermal Expansion | $$\delta = \alpha L (t_2 - t_1)$$ | $\delta$: Change in Length (m, in) $\alpha$: Coefficient of Thermal Expansion (1/°C, 1/°F) $L$: Original Length (m, in) $t_2$: Final Temperature (°C, °F) $t_1$: Initial Temperature (°C, °F) | Material: $\alpha$ - specific to material. | Material: $\alpha$. Geometric: $L$. | | Design Stress | $$\sigma_d = \frac{S_y}{FS} = \frac{S_u}{FS}$$ | $\sigma_d$: Design Stress (Pa, psi) $S_y$: Yield Strength (Pa, psi) $S_u$: Ultimate Tensile Strength (Pa, psi) $FS$: Factor of Safety (dimensionless) | Material: $S_y$, $S_u$ - specific to material. Reference: $FS$ is a design choice, typically $>1$. | Material: $S_y$, $S_u$. | | Modulus of Elasticity | $$S = E \epsilon$$ | $S$: Stress (Pa, psi) $E$: Modulus of Elasticity (Pa, psi) $\epsilon$: Strain (dimensionless) | Material: $E$ - specific to material. | Material: $E$. | | Modulus of Rigidity | $$G = \frac{E}{2(1+\mu)}$$ | $G$: Modulus of Rigidity (Pa, psi) $E$: Modulus of Elasticity (Pa, psi) $\mu$: Poisson's Ratio (dimensionless) | Material: $E$, $\mu$ - specific to material. | Material: $E$, $\mu$. | | Combined Stresses (Normal) | $$S = \frac{F}{A} \pm \frac{Mc}{I}$$ | $S$: Combined Normal Stress (Pa, psi) $F$: Axial Force (N, lbf) $A$: Cross-sectional Area (m$^2$, in$^2$) $M$: Bending Moment (N·m, lbf·in) $c$: Distance from Neutral Axis to Outer Fiber (m, in) $I$: Area Moment of Inertia (m$^4$, in$^4$) | None | Geometric: $A$, $c$, $I$. | | Stmax (Normal & Shear) | $$S_{tmax} = \frac{S_x}{2} \pm \sqrt{\left(\frac{S_x}{2}\right)^2 + S_s^2}$$ | $S_{tmax}$: Maximum Principal Normal Stress (Pa, psi) $S_x$: Normal Stress (Pa, psi) $S_s$: Shear Stress (Pa, psi) | None | None | | Ssmax (Normal & Shear) | $$S_{smax} = \sqrt{\left(\frac{S_x}{2}\right)^2 + S_s^2}$$ | $S_{smax}$: Maximum Shear Stress (Pa, psi) $S_x$: Normal Stress (Pa, psi) $S_s$: Shear Stress (Pa, psi) | None | None | | Stmax (Combined Moment & Torque) | $$S_{tmax} = \frac{16}{\pi D^3} [M + \sqrt{M^2 + T^2}]$$ | $S_{tmax}$: Maximum Principal Normal Stress (Pa, psi) $M$: Bending Moment (N·m, lbf·in) $T$: Torque (N·m, lbf·in) $D$: Diameter (m, in) | None | Geometric: $D$. | | Ssmax (Combined Moment & Torque) | $$S_{smax} = \frac{16}{\pi D^3} \sqrt{M^2 + T^2}$$ | $S_{smax}$: Maximum Shear Stress (Pa, psi) $M$: Bending Moment (N·m, lbf·in) $T$: Torque (N·m, lbf·in) $D$: Diameter (m, in) | None | Geometric: $D$. | | Stmax (Combined Moment, Torque, Axial) | $$S_{tmax} = \frac{16}{\pi D^3} \left[\left(M + \frac{F_a D}{8}\right) + \sqrt{\left(M + \frac{F_a D}{8}\right)^2 + T^2}\right]$$ | $S_{tmax}$: Maximum Principal Normal Stress (Pa, psi) $M$: Bending Moment (N·m, lbf·in) $F_a$: Axial Force (N, lbf) $D$: Diameter (m, in) $T$: Torque (N·m, lbf·in) | None | Geometric: $D$. | | Ssmax (Combined Moment, Torque, Axial) | $$S_{smax} = \frac{16}{\pi D^3} \sqrt{\left(M + \frac{F_a D}{8}\right)^2 + T^2}$$ | $S_{smax}$: Maximum Shear Stress (Pa, psi) $M$: Bending Moment (N·m, lbf·in) $F_a$: Axial Force (N, lbf) $D$: Diameter (m, in) $T$: Torque (N·m, lbf·in) | None | Geometric: $D$. | | Stmax (with shock factors) | $$S_{tmax} = \frac{16}{\pi D^3} [(k_mM) + \sqrt{(k_mM)^2 + (k_sT)^2}]$$ | $S_{tmax}$: Maximum Principal Normal Stress with shock factors (Pa, psi) $k_m$: Moment shock factor (dimensionless) $M$: Bending Moment (N·m, lbf·in) $k_s$: Torsion shock factor (dimensionless) $T$: Torque (N·m, lbf·in) $D$: Diameter (m, in) | None | Geometric: $D$. | | Ssmax (with shock factors) | $$S_{smax} = \frac{16}{\pi D^3} \sqrt{(k_mM)^2 + (k_sT)^2}$$ | $S_{smax}$: Maximum Shear Stress with shock factors (Pa, psi) $k_m$: Moment shock factor (dimensionless) $M$: Bending Moment (N·m, lbf·in) $k_s$: Torsion shock factor (dimensionless) $T$: Torque (N·m, lbf·in) $D$: Diameter (m, in) | None | Geometric: $D$. | | Vertical Shear (Beam) | $$S_v = \frac{4V}{3A}$$ | $S_v$: Vertical Shear Stress (Pa, psi) $V$: Shear Force (N, lbf) $A$: Cross-sectional Area (m$^2$, in$^2$) | None | Geometric: $A$. | | Angular Deformation | $$\theta = \frac{TL}{JG}$$ | $\theta$: Angle of Twist (radians) $T$: Torque (N·m, lbf·in) $L$: Length of Shaft (m, in) $J$: Polar Moment of Inertia (m$^4$, in$^4$) $G$: Modulus of Rigidity (Pa, psi) | Material: $G$. | Geometric: $L$, $J$. Material: $G$. | ### Variable Stresses | Name of Formula | LaTeX Equation (2-Line Format) | Parameter Definitions & Units | Essential Constants & Reference Values | Summary of Geometric and Material Constants: (Geometric Calculation Constants, Material Reference Constants) | |---|---|---|---|---| | Ductile Materials (Goodman/Soderberg) | $$\frac{1}{FS} = \frac{S_m}{S_y} + \frac{S_a}{S_n}$$ | $FS$: Factor of Safety (dimensionless) $S_m$: Mean Stress (Pa, psi) $S_y$: Yield Strength (Pa, psi) $S_a$: Alternating Stress (Pa, psi) $S_n$: Endurance Limit (Pa, psi) | Material: $S_y$, $S_n$ - specific to material. Reference: $FS$ is a design choice. | Material: $S_y$, $S_n$. | | Brittle Materials (Goodman/Soderberg) | $$\frac{1}{FS} = \frac{S_m}{S_u} + \frac{S_a}{S_n}$$ | $FS$: Factor of Safety (dimensionless) $S_m$: Mean Stress (Pa, psi) $S_u$: Ultimate Tensile Strength (Pa, psi) $S_a$: Alternating Stress (Pa, psi) $S_n$: Endurance Limit (Pa, psi) | Material: $S_u$, $S_n$ - specific to material. Reference: $FS$ is a design choice. | Material: $S_u$, $S_n$. | ### Shaftings | Name of Formula | LaTeX Equation (2-Line Format) | Parameter Definitions & Units | Essential Constants & Reference Values | Summary of Geometric and Material Constants: (Geometric Calculation Constants, Material Reference Constants) | |---|---|---|---|---| | Power Transmission (HP, inches, rpm) | $$P = \frac{D^3 N}{80}$$ (for line shaft) $$P = \frac{D^3 N}{53.5}$$ (for short shaft) $$P = \frac{D^3 N}{38}$$ | $P$: Power (hp) $D$: Diameter of shaft (in) $N$: Rotational Speed (rpm) | Constants: 80, 53.5, 38 are empirical for specific shaft types/materials. | Geometric: $D$. | | Diameter (from Torque & Shear Stress) | $$D = \sqrt[3]{\frac{5.1 T}{S_s}}$$ | $D$: Diameter of shaft (in) $T$: Torque (lbf·in) $S_s$: Allowable Shear Stress (psi) | None | Geometric: $D$. Material: $S_s$. | | Power (kW, N-mm, rpm) | $$P = \frac{TN}{9459000}$$ | $P$: Power (kW) $T$: Torque (N·mm) $N$: Rotational Speed (rpm) | Constant: 9459000 is a conversion factor for units. | None | | Power (hp, lbf-in, rpm) | $$P = \frac{TN}{63025}$$ | $P$: Power (hp) $T$: Torque (lbf·in) $N$: Rotational Speed (rpm) | Constant: 63025 is a conversion factor for units. | None | ### Keys | Name of Formula | LaTeX Equation (2-Line Format) | Parameter Definitions & Units | Essential Constants & Reference Values | Summary of Geometric and Material Constants: (Geometric Calculation Constants, Material Reference Constants) | |---|---|---|---|---| | Shearing Stress (Key) | $$\tau_s = \frac{2T}{wLD}$$ | $\tau_s$: Shearing Stress (Pa, psi) $T$: Torque (N·m, lbf·in) $w$: Width of key (m, in) $L$: Length of key (m, in) $D$: Diameter of shaft (m, in) | None | Geometric: $w, L, D$. | | Compressive Stress (Key) | $$\sigma_c = \frac{4T}{hLD}$$ | $\sigma_c$: Compressive Stress (Pa, psi) $T$: Torque (N·m, lbf·in) $h$: Height of key (m, in) $L$: Length of key (m, in) $D$: Diameter of shaft (m, in) | None | Geometric: $h, L, D$. | | Same Material (Key Length) | $$L = 1.18D$$ | $L$: Length of key (m, in) $D$: Diameter of shaft (m, in) | Constant: 1.18 is an empirical factor for "same material" keys. | Geometric: $D$. | ### Splines | Name of Formula | LaTeX Equation (2-Line Format) | Parameter Definitions & Units | Essential Constants & Reference Values | Summary of Geometric and Material Constants: (Geometric Calculation Constants, Material Reference Constants) | |---|---|---|---|---| | Shearing (Spline) | $$\tau_s = \frac{2T}{wLDN_t}$$ | $\tau_s$: Shearing Stress (Pa, psi) $T$: Torque (N·m, lbf·in) $w$: Width of spline (m, in) $L$: Length of spline (m, in) $D$: Pitch diameter of spline (m, in) $N_t$: Number of teeth (dimensionless) | None | Geometric: $w, L, D, N_t$. | | Compression (Spline) | $$\sigma_c = \frac{4T}{hLR_m N_t}$$ | $\sigma_c$: Compressive Stress (Pa, psi) $T$: Torque (N·m, lbf·in) $h$: Height of spline (m, in) $L$: Length of spline (m, in) $R_m$: Mean radius of spline (m, in) $N_t$: Number of teeth (dimensionless) | None | Geometric: $h, L, R_m, N_t$. | | Total Torque (Spline) | $$T = FR_m$$ | $T$: Total Torque (N·m, lbf·in) $F$: Force on spline (N, lbf) $R_m$: Mean radius of spline (m, in) | None | Geometric: $R_m$. | | Total Capacity (Spline) | $$T_c = \frac{T}{N_t} \times 1.1$$ | $T_c$: Total Capacity per tooth (N·m, lbf·in) $T$: Total Torque (N·m, lbf·in) $N_t$: Number of teeth (dimensionless) | Constant: 1.1 is an empirical factor. | Geometric: $N_t$. | ### Coupling | Name of Formula | LaTeX Equation (2-Line Format) | Parameter Definitions & Units | Essential Constants & Reference Values | Summary of Geometric and Material Constants: (Geometric Calculation Constants, Material Reference Constants) | |---|---|---|---|---| | Shearing of Bolt | $$T = \frac{S_s \pi D_b^2 D_{bc} N_B}{8}$$ | $T$: Torque (N·m, lbf·in) $S_s$: Allowable Shear Stress of bolt material (Pa, psi) $D_b$: Diameter of bolt (m, in) $D_{bc}$: Bolt Circle Diameter (m, in) $N_B$: Number of bolts (dimensionless) | Material: $S_s$. | Geometric: $D_b, D_{bc}, N_B$. Material: $S_s$. | | Compression of Bolt | $$T = \frac{S_c \pi D_t D_{bc} N_B}{2}$$ | $T$: Torque (N·m, lbf·in) $S_c$: Allowable Compressive Stress of bolt material (Pa, psi) $D_t$: Diameter of bolt at root of thread (m, in) $D_{bc}$: Bolt Circle Diameter (m, in) $N_B$: Number of bolts (dimensionless) | Material: $S_c$. | Geometric: $D_t, D_{bc}, N_B$. Material: $S_c$. | ### Threaded Members | Name of Formula | LaTeX Equation (2-Line Format) | Parameter Definitions & Units | Essential Constants & Reference Values | Summary of Geometric and Material Constants: (Geometric Calculation Constants, Material Reference Constants) | |---|---|---|---|---| | Valiance (Stresses) | $$S_w = C A_R^{0.418}$$ | $S_w$: Working Stress (Pa, psi) $C$: Bolt constant (Pa, psi) $A_R$: Root area of thread (m$^2$, in$^2$) | Bolt Constants: Bronze $C=10000$, Carbon Steel $C=5000$, Alloy Steel $C=1500$. | Material: $C$. Geometric: $A_R$. | | Faires (Stresses) | $$S_d = \frac{S_y}{6} A_s^{0.50}$$ | $S_d$: Design Stress (Pa, psi) $S_y$: Yield Strength (Pa, psi) $A_s$: Shear area of thread (m$^2$, in$^2$) | Material: $S_y$. | Material: $S_y$. Geometric: $A_s$. | | Valiance (Applied Load) | $$F_a = C A_R^{1.418}$$ | $F_a$: Applied Load (N, lbf) $C$: Bolt constant (Pa, psi) $A_R$: Root area of thread (m$^2$, in$^2$) | Bolt Constants: Bronze $C=10000$, Carbon Steel $C=5000$, Alloy Steel $C=1500$. | Material: $C$. Geometric: $A_R$. | | Faires (Applied Load) | $$F_e = \frac{S_y}{6} A_s^{1.50}$$ | $F_e$: Equivalent Applied Load (N, lbf) $S_y$: Yield Strength (Pa, psi) $A_s$: Shear area of thread (m$^2$, in$^2$) | Material: $S_y$. | Material: $S_y$. Geometric: $A_s$. | | Working Strength of Bolt | $$W_s = S_t [0.55d^2 - 0.25d]$$ | $W_s$: Working Strength (N, lbf) $S_t$: Tensile Strength (Pa, psi) $d$: Nominal diameter of bolt (m, in) | Material: $S_t$. | Geometric: $d$. Material: $S_t$. | | Bolt Spacing | $$Z = \frac{\pi D_{bc}}{N_T}$$ | $Z$: Bolt Spacing (m, in) $D_{bc}$: Bolt Circle Diameter (m, in) $N_T$: Number of bolts/threads (dimensionless) | None | Geometric: $D_{bc}, N_T$. | | Bolt Circle Diameter | $$D_{bc} = D_1 + 2D_b$$ | $D_{bc}$: Bolt Circle Diameter (m, in) $D_1$: Inner Diameter (m, in) $D_b$: Bolt Diameter (m, in) | None | Geometric: $D_1, D_b$. | | Depth Tap (Brittle) | $$h = 1.5 D$$ | $h$: Depth of tap (m, in) $D$: Nominal diameter of bolt (m, in) | Constant: 1.5 is an empirical factor for brittle materials. | Geometric: $D$. Material: Brittle. | | Depth Tap (Valiance Steel) | $$h = 1.25 D$$ | $h$: Depth of tap (m, in) $D$: Nominal diameter of bolt (m, in) | Constant: 1.25 is an empirical factor for Valiance steel. | Geometric: $D$. Material: Valiance Steel. | | Depth Tap (Faires S,WI) | $$h = D$$ | $h$: Depth of tap (m, in) $D$: Nominal diameter of bolt (m, in) | None | Geometric: $D$. Material: Faires S,WI. | | Initial Torque (Valiance) | $$T = 0.20 F_i D$$ | $T$: Initial Torque (N·m, lbf·in) $F_i$: Initial Tension (N, lbf) $D$: Nominal diameter of bolt (m, in) | Constant: 0.20 is an empirical friction factor. | Geometric: $D$. | | Initial Torque (Lubricated) | $$T = 0.20 F_i D$$ | $T$: Initial Torque (N·m, lbf·in) $F_i$: Initial Tension (N, lbf) $D$: Nominal diameter of bolt (m, in) | Constant: 0.20 is an empirical friction factor for lubricated conditions. | Geometric: $D$. | | Initial Torque (As received) | $$T = 0.15 F_i D$$ | $T$: Initial Torque (N·m, lbf·in) $F_i$: Initial Tension (N, lbf) $D$: Nominal diameter of bolt (m, in) | Constant: 0.15 is an empirical friction factor for "as received" conditions. | Geometric: $D$. | | Initial Tension (Reference) | $$F_i = 16000 D$$ | $F_i$: Initial Tension (N, lbf) $D$: Nominal diameter of bolt (m, in) | Constant: 16000 is an empirical factor (units depend on $D$). | Geometric: $D$. | ### Power Screw | Name of Formula | LaTeX Equation (2-Line Format) | Parameter Definitions & Units | Essential Constants & Reference Values | Summary of Geometric and Material Constants: (Geometric Calculation Constants, Material Reference Constants) | |---|---|---|---|---| | Collar Friction Torque | $$T_c = \left(\frac{W D_c}{2}\right) f_c$$ | $T_c$: Collar friction torque (N·m, lbf·in) $W$: Axial Load (N, lbf) $D_c$: Mean collar diameter (m, in) $f_c$: Coefficient of friction for collar (dimensionless) | Material: $f_c$. | Geometric: $D_c$. Material: $f_c$. | | Raising/Lowering Torque (Square Thread) | $$T_f = \frac{WD_m}{2} \tan(\lambda \pm \beta)$$ | $T_f$: Torque to raise/lower load (N·m, lbf·in) $W$: Axial Load (N, lbf) $D_m$: Mean thread diameter (m, in) $\lambda$: Lead angle (rad) $\beta$: Friction angle (rad) | Material: $f = \tan(\beta)$. | Geometric: $D_m$. | | Raising/Lowering Torque (ACME Thread) | $$T_f = \frac{WD_m}{2} \frac{0.968f + \tan\alpha}{1 - 0.968f \tan\alpha}$$ | $T_f$: Torque to raise/lower load (N·m, lbf·in) $W$: Axial Load (N, lbf) $D_m$: Mean thread diameter (m, in) $f$: Coefficient of friction (dimensionless) $\alpha$: Half angle of thread (rad) | Material: $f$. Geometric: $\alpha$. | Geometric: $D_m, \alpha$. Material: $f$. | | Raising/Lowering Torque (Trapezoid Thread) | $$T_f = \frac{WD_m}{2} \frac{0.966f + \tan\alpha}{1 - 0.966f \tan\alpha}$$ | $T_f$: Torque to raise/lower load (N·m, lbf·in) $W$: Axial Load (N, lbf) $D_m$: Mean thread diameter (m, in) $f$: Coefficient of friction (dimensionless) $\alpha$: Half angle of thread (rad) | Material: $f$. Geometric: $\alpha$. | Geometric: $D_m, \alpha$. Material: $f$. | | Raising/Lowering Torque (American Thread) | $$T_f = \frac{WD_m}{2} \frac{0.866f + \tan\alpha}{1 - 0.866f \tan\alpha}$$ | $T_f$: Torque to raise/lower load (N·m, lbf·in) $W$: Axial Load (N, lbf) $D_m$: Mean thread diameter (m, in) $f$: Coefficient of friction (dimensionless) $\alpha$: Half angle of thread (rad) | Material: $f$. Geometric: $\alpha$. | Geometric: $D_m, \alpha$. Material: $f$. | | Total Torque (Power Screw) | $$T = T_f + T_c$$ | $T$: Total Torque (N·m, lbf·in) $T_f$: Torque to overcome thread friction (N·m, lbf·in) $T_c$: Torque to overcome collar friction (N·m, lbf·in) | None | None | | Efficiency (Power Screw) | $$e = \frac{P_o}{P_i} = \frac{WV}{2 \pi T N}$$ | $e$: Efficiency (dimensionless) $P_o$: Output Power (W, hp) $P_i$: Input Power (W, hp) $W$: Axial Load (N, lbf) $V$: Linear Velocity (m/s, in/s) $T$: Input Torque (N·m, lbf·in) $N$: Rotational Speed (rev/s, rpm) | None | None | | Friction Angle | $$\beta = \tan^{-1}(f)$$ | $\beta$: Friction angle (rad) $f$: Coefficient of friction (dimensionless) | Material: $f$. | Material: $f$. | | Linear Velocity (Power Screw) | $$V = NL$$ | $V$: Linear Velocity (m/s, in/s) $N$: Rotational Speed (rev/s, rpm) $L$: Lead (m, in) | None | Geometric: $L$. | | Lead Angle | $$\lambda = \tan^{-1}\left(\frac{L}{\pi D_m}\right)$$ | $\lambda$: Lead angle (rad) $L$: Lead (m, in) $D_m$: Mean thread diameter (m, in) | None | Geometric: $L, D_m$. | | Lead (Single, Double, Triple) | $$L = P$$ $$L = 2P$$ $$L = 3P$$ | $L$: Lead (m, in) $P$: Pitch (m, in) | None | Geometric: $P$. | | Outside Diameter (Handbook) | $$D_o = D_i + L/2$$ | $D_o$: Outside Diameter (m, in) $D_i$: Inside Diameter (m, in) $L$: Lead (m, in) | None | Geometric: $D_i, L$. | | Screw Diameter (from HP) | $$d = \left[\frac{50(HP)}{N}\right]^{1/2.3}$$ | $d$: Screw Diameter (in) $HP$: Horsepower (hp) $N$: Rotational Speed (rpm) | Constant: 50, 1/2.3 are empirical factors. | None | | TRMS Power (HP, N) | $$HP = \left(\frac{N}{4.6}\right)^{1.5}$$ (or) $$HP = \left(\frac{N}{5.3}\right)^{1.5}$$ | $HP$: Horsepower (hp) $N$: Power in N (Watts) | Constants: 4.6, 5.3 are empirical conversion factors. | None | | Shaft Diameter (L, ft) | $$D = \frac{L}{8.95}$$ | $D$: Shaft Diameter (in) $L$: Length of shaft (ft) | Constant: 8.95 is an empirical factor. | Geometric: $L$. | | Shaft Diameter (rpm, hp) | $$D = \frac{L}{5.3}$$ | $D$: Shaft Diameter (in) $L$: Length of shaft (ft) | Constant: 5.3 is an empirical factor. | Geometric: $L$. | ### Pressure Vessel | Name of Formula | LaTeX Equation (2-Line Format) | Parameter Definitions & Units | Essential Constants & Reference Values | Summary of Geometric and Material Constants: (Geometric Calculation Constants, Material Reference Constants) | |---|---|---|---|---| | Tangential Stress (Thin Walled Cylinder) | $$\sigma_t = \frac{P_i D_i}{2te}$$ | $\sigma_t$: Tangential (Hoop) Stress (Pa, psi) $P_i$: Internal Pressure (Pa, psi) $D_i$: Inner Diameter (m, in) $t$: Wall Thickness (m, in) $e$: Joint Efficiency (dimensionless) | None | Geometric: $D_i, t$. | | Longitudinal Stress (Thin Walled Cylinder) | $$\sigma_l = \frac{P_i D_i}{4t}$$ | $\sigma_l$: Longitudinal Stress (Pa, psi) $P_i$: Internal Pressure (Pa, psi) $D_i$: Inner Diameter (m, in) $t$: Wall Thickness (m, in) | None | Geometric: $D_i, t$. | | Tangential Stress (Thin Walled Sphere) | $$\sigma_t = \frac{P_i D_i}{4te}$$ | $\sigma_t$: Tangential Stress (Pa, psi) $P_i$: Internal Pressure (Pa, psi) $D_i$: Inner Diameter (m, in) $t$: Wall Thickness (m, in) $e$: Joint Efficiency (dimensionless) | Condition: $t > 0.1 r_i$. | Geometric: $D_i, t$. | | Thickness (Thick Walled Cylinder) | $$t = \frac{D_i}{2} \left[ \sqrt{\frac{S_t + P_i}{S_t - P_i}} - 1 \right]$$ | $t$: Wall Thickness (m, in) $D_i$: Inner Diameter (m, in) $S_t$: Allowable Stress (Pa, psi) $P_i$: Internal Pressure (Pa, psi) | Material: $S_t$. | Geometric: $D_i$. Material: $S_t$. | | Axial Stress (Thick Walled Cylinder) | $$\sigma_a = \frac{P_i r_i^2 - P_o r_o^2}{r_o^2 - r_i^2}$$ | $\sigma_a$: Axial Stress (Pa, psi) $P_i$: Internal Pressure (Pa, psi) $r_i$: Inner Radius (m, in) $P_o$: External Pressure (Pa, psi) $r_o$: Outer Radius (m, in) | None | Geometric: $r_i, r_o$. | | Max. Tensile Stress (Thick Walled Cylinder) | $$S_{tmax} = \frac{P_i r_i^2 (r_o^2 + r^2)}{r^2 (r_o^2 - r_i^2)}$$ | $S_{tmax}$: Maximum Tensile Stress (Pa, psi) $P_i$: Internal Pressure (Pa, psi) $r_i$: Inner Radius (m, in) $r_o$: Outer Radius (m, in) $r$: Radius at which stress is calculated (m, in) | None | Geometric: $r_i, r_o, r$. | | Max. Shear Stress (Thick Walled Cylinder) | $$S_{smax} = \frac{P_i r_i^2}{r_o^2 - r_i^2}$$ | $S_{smax}$: Maximum Shear Stress (Pa, psi) $P_i$: Internal Pressure (Pa, psi) $r_i$: Inner Radius (m, in) $r_o$: Outer Radius (m, in) | None | Geometric: $r_i, r_o$. | | Equivalent Max. Tensile (Thick Walled Cylinder) | $$S_{tmax} = \frac{2 P_i r_i^2}{r_o^2 - r_i^2}$$ | $S_{tmax}$: Equivalent Maximum Tensile Stress (Pa, psi) $P_i$: Internal Pressure (Pa, psi) $r_i$: Inner Radius (m, in) $r_o$: Outer Radius (m, in) | None | Geometric: $r_i, r_o$. | | Critical Pressure (Thin Tubes, Stainless Steel, $t/d_o $t$: Wall Thickness (m, in) $d_o$: Outer Diameter (m, in) | Constant: 50,200,000 is an empirical constant for stainless steel. | Geometric: $t, d_o$. Material: Stainless Steel. | | Critical Pressure (Thin Tubes, Stainless Steel, $t/d_o > 0.03$) | $$P_{cr} = 95,520 \left(\frac{t}{d_o}\right) - 2090$$ | $P_{cr}$: Critical Buckling Pressure (Pa, psi) $t$: Wall Thickness (m, in) $d_o$: Outer Diameter (m, in) | Constants: 95,520 and 2090 are empirical constants for stainless steel. | Geometric: $t, d_o$. Material: Stainless Steel. | | Critical Pressure (Lap-welded Steel Tubes, $t/d_o > 0.03$) | $$P_{cr} = 83,290 \left(\frac{t}{d_o}\right) - 1025$$ | $P_{cr}$: Critical Buckling Pressure (Pa, psi) $t$: Wall Thickness (m, in) $d_o$: Outer Diameter (m, in) | Constants: 83,290 and 1025 are empirical constants for lap-welded steel. | Geometric: $t, d_o$. Material: Lap-welded Steel. |