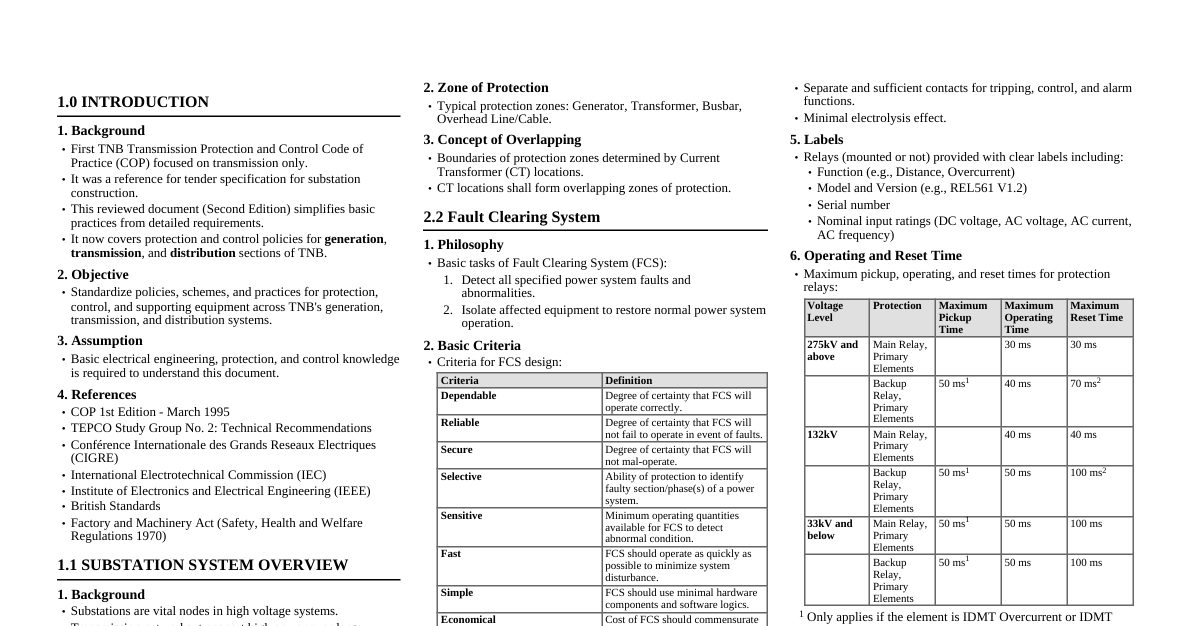

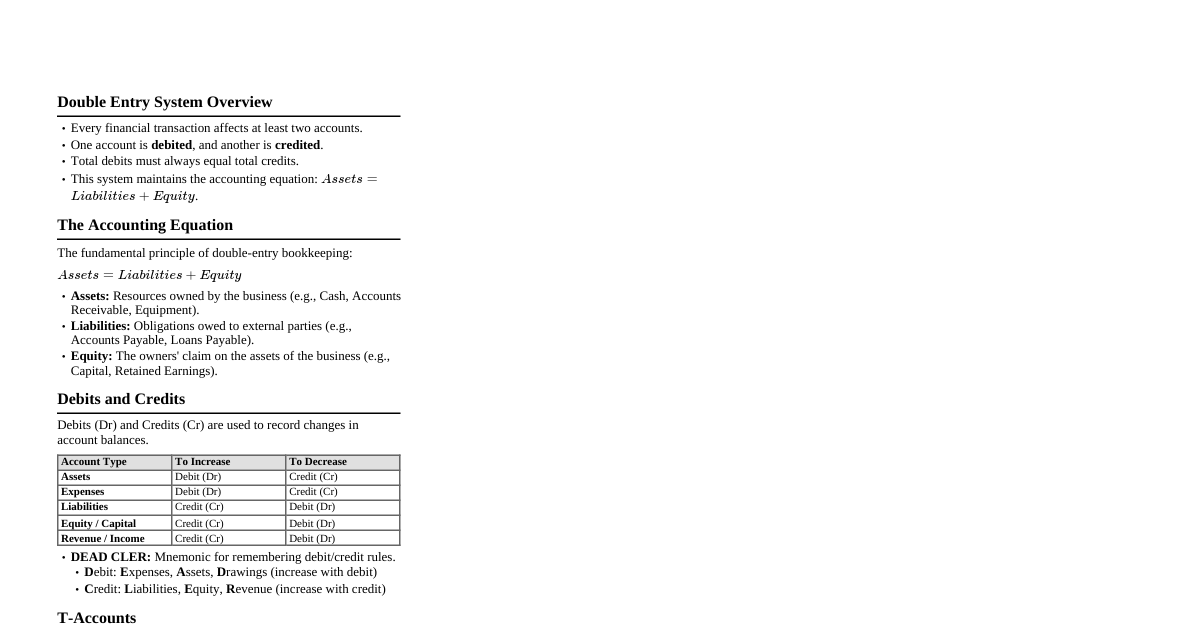

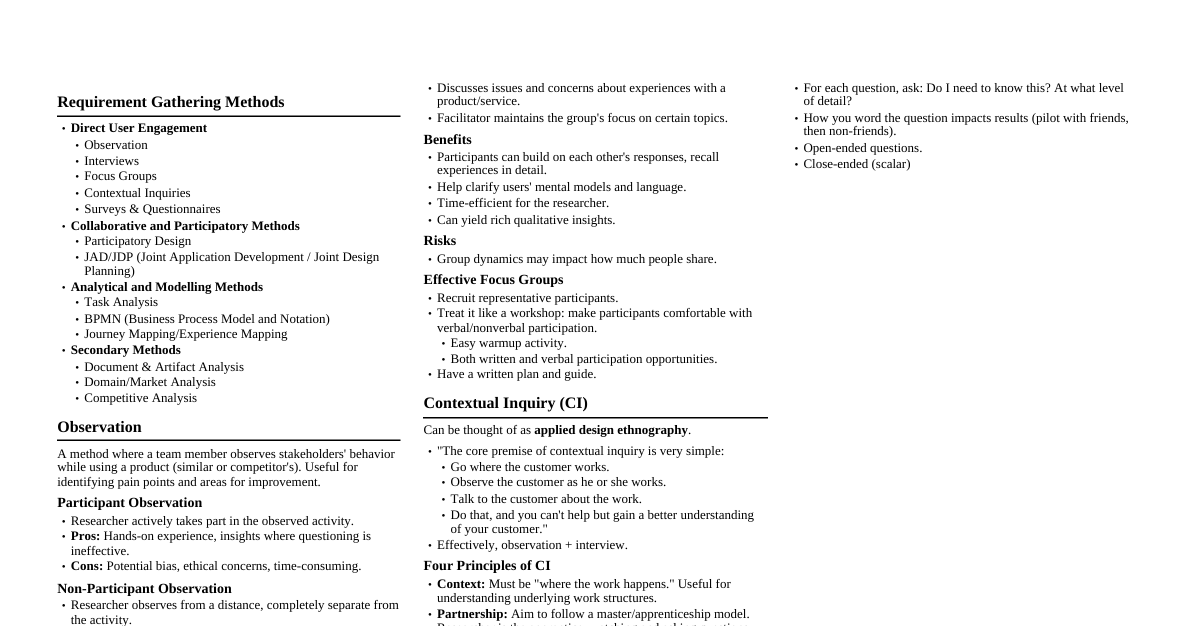

### Introduction to P&ID - **P&ID (Piping and Instrumentation Diagram):** A detailed diagram in the process industry showing the piping and process equipment together with the instrumentation and control devices. - **Purpose:** - Visual representation of process control schemes. - Aids in plant design, construction, operation, and maintenance. - Essential for safety and regulatory compliance. - **Key Elements:** Process equipment, piping, valves, instruments, control loops, and associated symbols. ### Instrumentation Symbols - **General Instrument Symbol:** - Circle: Discrete instrument (field mounted) - Circle with a line: Board mounted (primary location) - Circle with two lines: Auxiliary board mounted (secondary location) - Square with a circle: DCS (Distributed Control System) function - **Letter Codes (ISA S5.1):** - **First Letter (Measured Variable):** - `F`: Flow - `L`: Level - `P`: Pressure - `T`: Temperature - `A`: Analysis - **Succeeding Letters (Function/Modifier):** - `I`: Indicating - `C`: Controlling - `R`: Recording - `T`: Transmitting - `V`: Valve - `H`: High - `L`: Low - `A`: Alarm - `E`: Element (primary element) - **Examples:** - `FIC`: Flow Indicating Controller - `LIT`: Level Indicating Transmitter - `PSV`: Pressure Safety Valve - `TE`: Temperature Element ### Control Loop Components - **Primary Element:** Senses the process variable (e.g., orifice plate for flow, thermocouple for temperature, float for level). - **Transmitter (T):** Converts the sensor signal into a standard output (e.g., 4-20mA, 0-10V, digital). - **Controller (C):** Receives the signal from the transmitter, compares it to a setpoint, and determines the appropriate output to the final control element. - **Types:** PID (Proportional-Integral-Derivative), ON/OFF, Ratio, Cascade. - **Final Control Element (FCE):** Actuates the control action based on the controller's output (e.g., control valve, motor, heater). - **Indicator (I):** Displays the current value of the process variable. - **Recorder (R):** Logs the historical data of the process variable. - **Alarm (A):** Alerts operators to abnormal conditions (e.g., high-high, high, low, low-low). ### Control Strategies - **Feedback Control (Closed Loop):** - Measures the output, compares it to a setpoint, and adjusts the input to minimize the error. - Most common type. - Example: `FIC` controlling a pump speed based on measured flow. - **Feedforward Control:** - Measures disturbances and adjusts the input before they affect the output. - Requires knowledge of process dynamics. - Often combined with feedback control. - **Cascade Control:** - Two controllers in series: a master (primary) controller and a slave (secondary) controller. - Master controls the main process variable, slave controls a secondary variable that affects the main variable. - Example: Temperature controller (master) adjusting the setpoint of a flow controller (slave) for cooling water. - **Ratio Control:** - Maintains a fixed ratio between two or more process variables. - Example: Blending two streams to maintain a specific composition. - **Split-Range Control:** - A single controller output manipulates two or more final control elements, each operating in a different portion of the controller's output range. - Example: A temperature controller manipulating both a cooling valve and a heating valve. ### Types of Control Valves - **Globe Valve:** Good for throttling and flow regulation. - **Ball Valve:** Excellent for ON/OFF service, poor for throttling. - **Butterfly Valve:** Good for large flow rates, ON/OFF and throttling. - **Diaphragm Valve:** Good for slurries and corrosive fluids. - **Gate Valve:** Primarily for ON/OFF service, minimal pressure drop when fully open. - **Actuators:** - **Pneumatic:** Air pressure operates the valve. - **Electric:** Motor operates the valve. - **Hydraulic:** Fluid pressure operates the valve. - **Fail-Safe Position:** - **FC (Fail Close):** Valve closes on loss of power/signal. - **FO (Fail Open):** Valve opens on loss of power/signal. - **FL (Fail Last):** Valve stays in last position on loss of power/signal. ### Electrical Instrumentation - **Transmitters:** - **Pressure Transmitter (PT):** Converts pressure into an electrical signal. - **Temperature Transmitter (TT):** Converts temperature (from RTD/Thermocouple) into an electrical signal. - **Flow Transmitter (FT):** Converts flow (from orifice, magnetic, vortex etc.) into an electrical signal. - **Level Transmitter (LT):** Converts level (from differential pressure, ultrasonic, radar etc.) into an electrical signal. - **Signals:** - **Analog:** 4-20mA (current loop, most common), 0-10V, 1-5V. - **Digital:** HART, Foundation Fieldbus, Profibus, Modbus. - **Wiring:** - **Two-wire:** Power and signal share the same pair of wires. - **Four-wire:** Separate wires for power and signal. - **Shielding:** Used to protect signals from electromagnetic interference (EMI). - **Safety Systems:** - **ESD (Emergency Shutdown System):** Shuts down process in emergency. - **SIS (Safety Instrumented System):** Implements safety functions to achieve a safe state. - **SIL (Safety Integrity Level):** A measure of safety performance required for an SIS. ### Common P&ID Symbols | Item Type | Symbol | Description | |---|---|---| | **Piping** | | | | Process Line | | Major process flow | | Instrument Air Line | | Instrument air supply | | Electrical Signal | | Electrical connection | | **Valves** | | | | Globe Valve | | Flow control | | Ball Valve | | On/Off | | Check Valve | --" alt="Check valve symbol" /> | One-way flow | | Control Valve | | Automated flow control | | **Instruments** | | | | Field Mounted | $\bigcirc$ | Discrete instrument | | Panel Mounted | $\textcircled{--}$ | Primary panel mounted | | DCS Function | $\textcircled{\text{X}}$ | Distributed Control System | | **Equipment** | | | | Pump | $\textcircled{P}$ | Centrifugal pump | | Heat Exchanger | $\textcircled{E}$ | Shell and tube | | Tank | $\textcircled{T}$ | Storage tank |