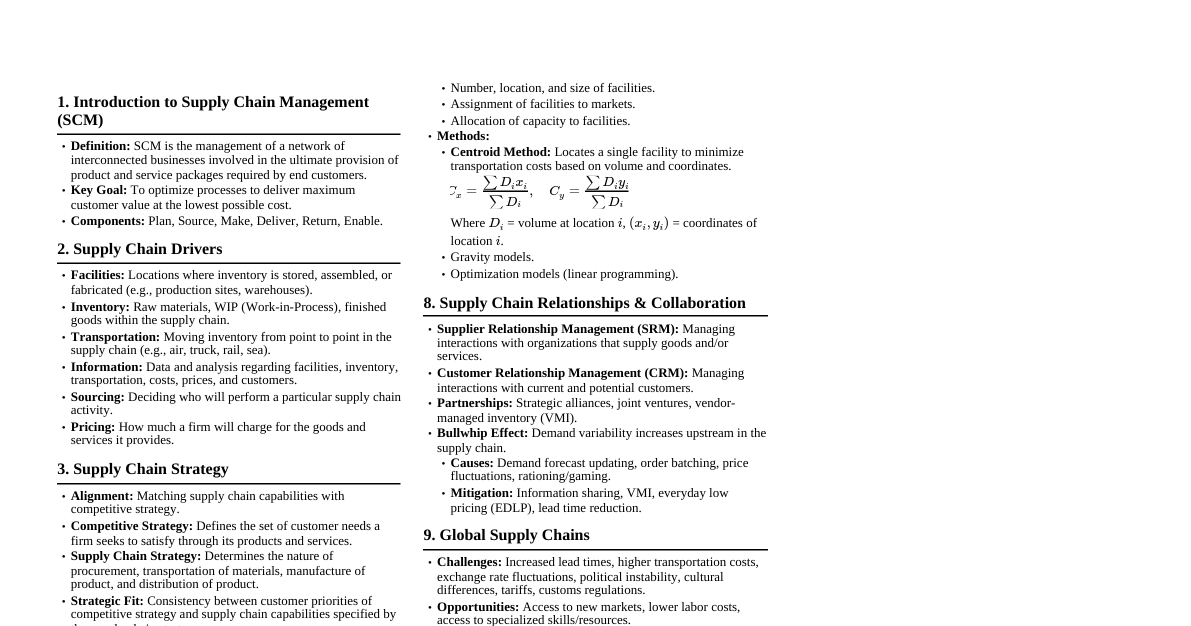

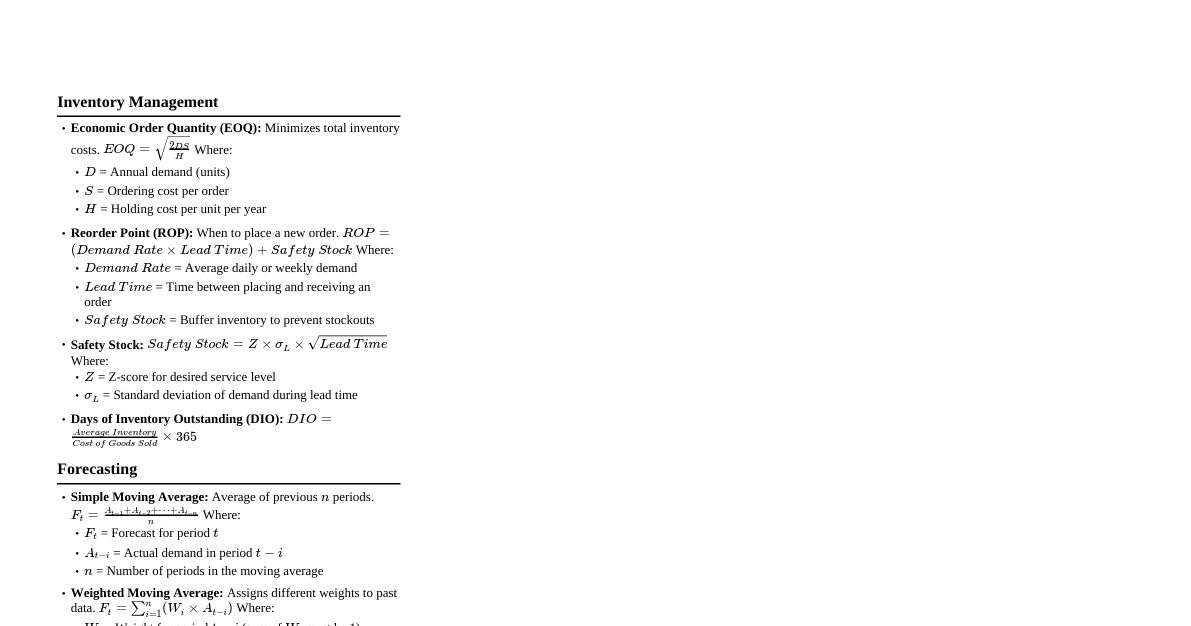

1. Introduction to Supply Chain Management (SCM) Definition: The management of a network of interconnected businesses involved in the ultimate provision of product and service packages required by end customers. Key Functions: Planning, Sourcing, Making, Delivering, Returning, Enabling. Goals: Maximize customer value and achieve a sustainable competitive advantage. 2. Supply Chain Drivers Facilities: Locations where inventory is stored, assembled, or fabricated. Production sites, warehouses, distribution centers. Trade-off: Responsiveness vs. Efficiency (more facilities $\rightarrow$ more responsive, less efficient). Inventory: Raw materials, WIP (Work-in-Progress), finished goods. Trade-off: Responsiveness vs. Efficiency (more inventory $\rightarrow$ more responsive, less efficient). Transportation: Moving inventory between supply chain locations. Modes: Air, truck, rail, ship, pipeline, electronic. Trade-off: Responsiveness vs. Efficiency (faster modes $\rightarrow$ more responsive, more costly). Information: Data and analysis regarding facilities, inventory, transportation, costs, prices, and customers. Enables effective management of other drivers. Crucial for coordination and decision-making. Sourcing: Deciding which activities are performed in-house and which are outsourced. Trade-off: Better economies of scale vs. loss of control. Pricing: How a company charges for its goods and services. Affects demand and profitability. 3. Supply Chain Flows Product Flow: Movement of goods from suppliers to customers, including returns. Information Flow: Transmitting orders, tracking shipments, sharing forecasts, and collaborating on designs. Financial Flow: Credit terms, payment schedules, and consignment arrangements. 4. Supply Chain Strategies Efficient Supply Chains: Focus on cost reduction and maximizing asset utilization. Best for functional products (predictable demand, long life cycles). Responsive Supply Chains: Focus on speed, flexibility, and customer service. Best for innovative products (unpredictable demand, short life cycles). Push Strategy: Production and distribution decisions based on long-term forecasts. High inventory, economies of scale, lower transportation costs. Pull Strategy: Production and distribution decisions driven by actual demand. Lower inventory, higher responsiveness, often higher costs. Push-Pull Strategy: Combines both; push for the initial stages, pull for the final stages. Decoupling point separates the push and pull phases. 5. Inventory Management Types of Inventory: Raw Materials, Work-in-Progress (WIP), Finished Goods. Transit Inventory (in pipeline), Buffer/Safety Stock, Anticipation Inventory. Economic Order Quantity (EOQ): Optimal order quantity that minimizes total holding and ordering costs. $$ EOQ = \sqrt{\frac{2DS}{H}} $$ Where $D$ = Annual Demand, $S$ = Ordering Cost per order, $H$ = Holding Cost per unit per year. Reorder Point (ROP): Level of inventory at which a new order should be placed. $$ ROP = \text{Demand per day} \times \text{Lead time in days} + \text{Safety Stock} $$ Inventory Turnover: How many times inventory is sold or used in a period. $$ \text{Inventory Turnover} = \frac{\text{Cost of Goods Sold}}{\text{Average Inventory}} $$ 6. Forecasting Qualitative Methods: Expert opinion, Delphi method, market research. Quantitative Methods: Time Series: Moving average, exponential smoothing. Causal: Regression analysis (e.g., demand as a function of price). Forecast Error: Mean Absolute Deviation (MAD): $MAD = \frac{\sum |A_t - F_t|}{n}$ Mean Squared Error (MSE): $MSE = \frac{\sum (A_t - F_t)^2}{n}$ Mean Absolute Percentage Error (MAPE): $MAPE = \frac{\sum \frac{|A_t - F_t|}{A_t}}{n} \times 100\%$ $A_t$ = Actual demand, $F_t$ = Forecasted demand, $n$ = Number of periods. 7. Logistics and Transportation Logistics: The part of SCM that plans, implements, and controls the efficient, effective forward and reverse flow and storage of goods, services, and related information between the point of origin and the point of consumption to meet customers' requirements. Transportation Modes: Mode Speed Cost Flexibility Capacity Air Very High Very High Low Low Truck High High High Medium Rail Medium Medium Medium High Water Low Low Low Very High Pipeline Very Low Very Low Very Low Medium Cross-docking: Unloading materials from an incoming semi-trailer truck or railroad car and loading these materials directly into outbound trucks, trailers, or rail cars, with little or no storage in between. 8. Supply Chain Risk Management Sources of Risk: Disruptions (natural disaster, geopolitical), delays, systems risks, forecast risks, intellectual property risks, procurement risks. Mitigation Strategies: Redundancy: Multiple suppliers, safety stock. Flexibility: Flexible contracts, adaptable processes. Visibility: Real-time tracking, information sharing. Hedge: Financial instruments, insurance. 9. Key Performance Indicators (KPIs) Customer Service: Order fulfillment rate, on-time delivery, order cycle time. Inventory: Inventory turnover, days of supply, inventory accuracy. Costs: Total supply chain cost, transportation cost per unit, warehousing cost. Quality: Defect rate, returns rate, supplier quality. Efficiency: Capacity utilization, labor productivity. 10. Sustainable Supply Chains Triple Bottom Line: People, Planet, Profit. Environmental Considerations: Carbon footprint, waste reduction, sustainable sourcing, reverse logistics (product returns, recycling, disposal). Social Considerations: Fair labor practices, ethical sourcing, community engagement. Economic Considerations: Long-term profitability, economic impact on communities.