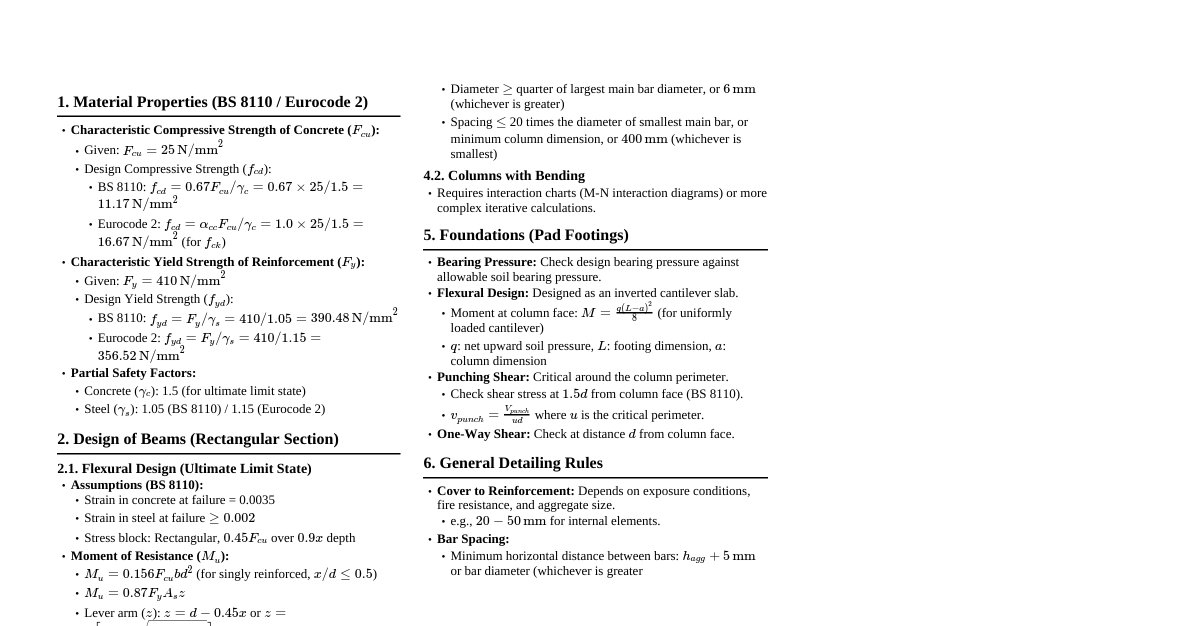

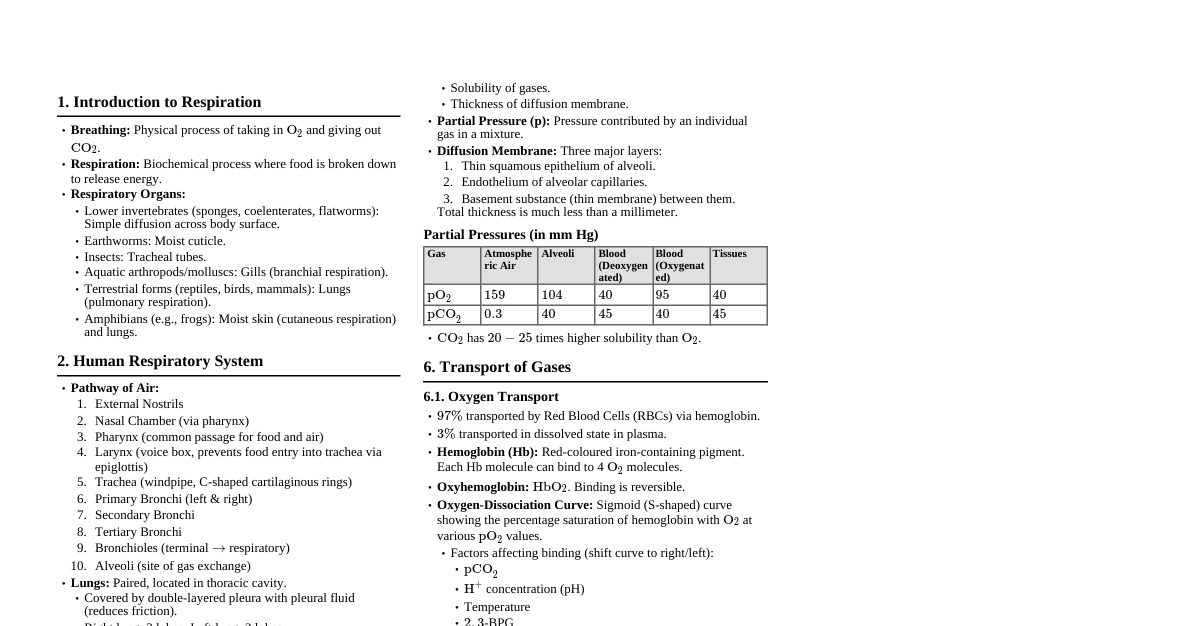

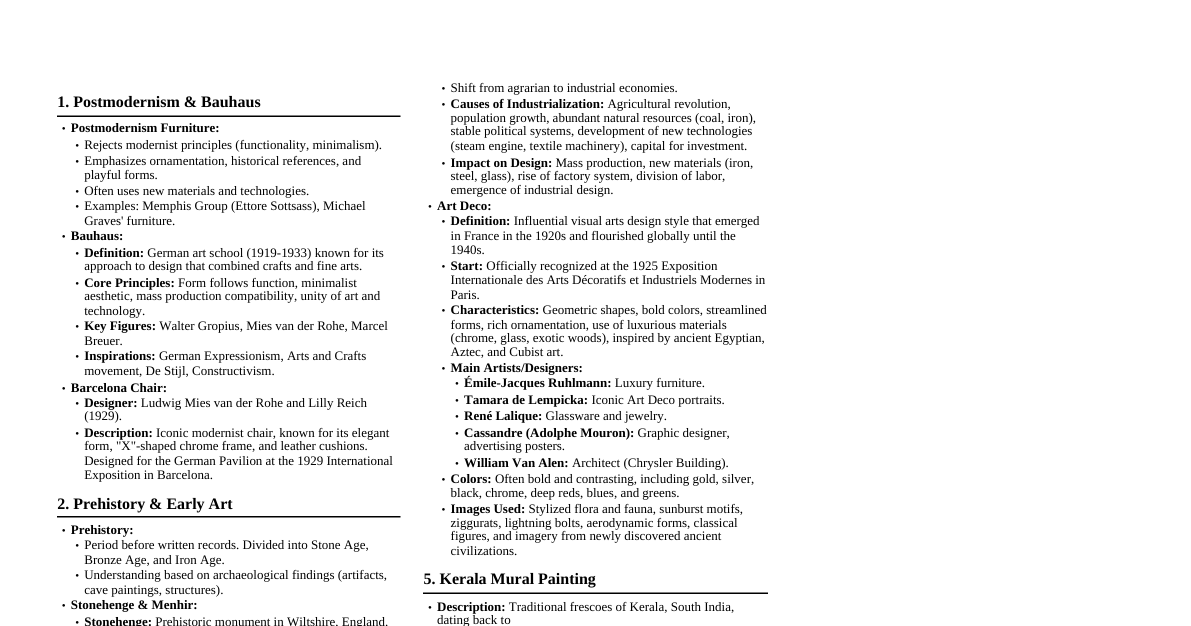

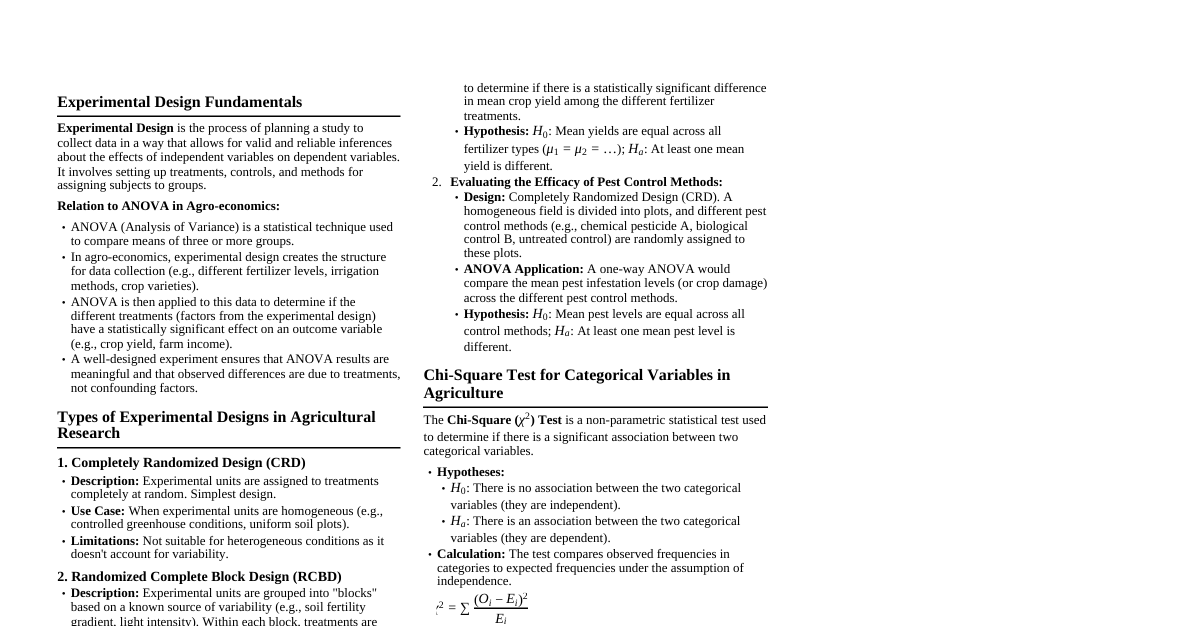

1. Scope and General Principles of Separation Purpose: This document outlines the process design criteria for pressure-vessel-based gas-liquid and gas-liquid-liquid separators. These include scrubbers, knockout drums, and free water knockouts. The primary goal is to separate immiscible fluid phases (gas from liquid, oil from water) efficiently. Types Covered: Vertical Separators: Cylindrical vessels with gas and liquid outlets. Often used for high gas-liquid ratio or where plot space is limited. Horizontal Separators: Cylindrical vessels with a larger liquid-gas interface area. Preferred for high liquid-gas ratio, foaming liquids, or three-phase separation. Conventional Internals: Focus is on designs utilizing standard internals such as: Inlet devices (e.g., half-open pipe, deflectors, cyclonic inlets) for initial bulk separation and momentum dissipation. Mist eliminators (e.g., mesh pads, vane packs, cyclones) for fine liquid droplet removal from gas. Agglomerators: Devices designed to coalesce small droplets into larger ones for easier separation. Distribution baffles: Used to promote plug flow and distribute fluids evenly within the vessel. Exclusions and Rationale: Spherical Separators: Less common due to complex fabrication and limited capacity per unit volume, though they offer high strength-to-weight ratio. Flare Knockout Drums: Specialized design for emergency relief, handling large, intermittent slugs and often operating at low pressures. Different sizing criteria apply. Electrostatic/Inline/Mono-cyclone Separators: Utilize specialized technologies (electric fields, direct inline separation, single cyclone units) for specific applications, outside the scope of conventional gravity/momentum-based designs. Filter Separators: Incorporate filter elements for very fine particle/droplet removal, typically for gas conditioning. De-oiling/De-sanding Equipment: Focuses on more specialized separation of oil from water (e.g., hydrocyclones, CPI units) or fine solids from liquids, often involving hydrocyclones or centrifuges. Key Design Aspects: Instrumentation: Proper selection and placement of pressure, temperature, and level sensors are crucial for safe and efficient operation, control, and safeguarding. Process vs. Mechanical Design: These are intrinsically linked. Process design defines the operating conditions and internal requirements, which directly dictate the mechanical design (vessel material, thickness, nozzle reinforcement, internal supports). A robust mechanical design ensures the vessel can withstand the process conditions and internal loads. 2. Terms and Definitions Company: The entity (owner/operator) that specifies the requirements for the separator. Technology Supplier: The vendor or engineering firm responsible for the detailed design of internal components and/or the complete process design of the separator. Abbreviations & Symbols: $A_f$: liquid film flow cross-sectional area ($m^2$) - Area available for liquid flow in a gas passage. $A_{g,h}$: horizontal vessel gas space area ($m^2$) - Cross-sectional area of the gas phase in a horizontal vessel. $A_{g,v}$: vertical vessel cross-sectional area ($m^2$) - Total cross-sectional area of a vertical vessel, relevant for gas flow. $A_N$: inlet nozzle area ($m^2$) - Internal cross-sectional area of the inlet nozzle. BOV: bottom of vessel (horizontal vessel) ($m$) - The lowest point of the horizontal vessel shell. BTL: bottom tangent line (vertical vessel) ($m$) - The lowest point of the cylindrical section of a vertical vessel. $C_D$: drag coefficient (dimensionless) - A dimensionless quantity used to quantify the drag or resistance of an object in a fluid environment. $D$: vessel ID ($m$) - Inside diameter of the main vessel shell. $D_g$: gas outlet nozzle ID ($m$) - Inside diameter of the gas outlet nozzle. $D_{in}$: inlet nozzle ID ($m$) - Inside diameter of the inlet nozzle. $D_h$: hydraulic diameter ($m$) - Used for non-circular ducts, $D_h = 4A/P_w$. $D_l$: liquid outlet nozzle ID ($m$) - Inside diameter of the general liquid outlet nozzle. $D_o$: oil outlet nozzle ID ($m$) - Inside diameter of the oil outlet nozzle in a three-phase separator. $D_p$: inlet pipe ID ($m$) - Inside diameter of the pipe leading into the separator. $D_w$: water outlet nozzle ID ($m$) - Inside diameter of the water outlet nozzle in a three-phase separator. $d_p$: particle diameter ($m$) - Diameter of a droplet or solid particle. $F_B$: buoyancy force ($N$) - Upward force exerted by a fluid that opposes the weight of an immersed object. $F_D$: drag force ($N$) - Resistance force exerted by a fluid on an object moving through it. $F_G$: gravity force ($N$) - Downward force due to gravity acting on an object. $Fr$: Froude number (dimensionless) - Ratio of inertial forces to gravitational forces, $Fr = V / \sqrt{gL}$. GVF: gas volume fraction (dimensionless) - Volume of gas divided by total fluid volume. $g$: gravitational acceleration ($m/s^2$) - Standard value is $9.81 m/s^2$. $H_s$: nozzle submergence ($m$) - Depth of a nozzle below the liquid level. $h$: droplet vertical fall distance ($m$) - Vertical distance a droplet travels during settling. ID: inside diameter ($m$) - Internal diameter. IVD: inlet vane diffuser - A type of inlet device that uses vanes to diffuse and direct incoming flow. $K$: K-factor ($m/s$) - Souders-Brown coefficient, used for sizing the gas-liquid disengagement area. $L_B$: baffle spacing ($m$) - Distance between baffles. $L_{g,eff}$: gas space effective separation length ($m$) - Length available for gas-liquid separation in the gas phase. $L_H$: droplet horizontal travel distance ($m$) - Horizontal distance a droplet travels during separation. $L_{IVD}$: IVD length ($m$) - Length of the inlet vane diffuser. $L_{l,eff}$: liquid space effective separation length ($m$) - Length available for liquid-liquid or liquid-solid separation. $L_N$: spacing from closest edge of gas outlet nozzle to mist eliminator outlet ($m$) - Critical for proper gas flow distribution. $L_{oiw,eff}$: oil space effective separation length ($m$) - Length for oil-water separation in the oil phase. $L_p$: length of inlet pipe ($m$) - Length of pipe before the inlet nozzle. $L_{TT}$: horizontal vessel tangent to tangent length ($m$) - Length of the cylindrical section of a horizontal vessel. $L_{wio,eff}$: water space effective separation length ($m$) - Length for oil-water separation in the water phase. LAH: high liquid level alarm ($m$) - Level at which an alarm is triggered due to high liquid. LAL: low liquid level alarm ($m$) - Level at which an alarm is triggered due to low liquid. LG: level gauge - Device for visual indication of liquid level. LIAH: high interface level alarm ($m$) - Alarm for high interface level in a three-phase separator. LIAL: low interface liquid level alarm ($m$) - Alarm for low interface level in a three-phase separator. LISH: high interface level trip ($m$) - Trip for high interface level, initiating automatic shutdown. LISL: low interface level trip ($m$) - Trip for low interface level, initiating automatic shutdown. LSH: high liquid level trip ($m$) - Trip for high liquid level, initiating automatic shutdown. LSL: low liquid level trip ($m$) - Trip for low liquid level, initiating automatic shutdown. LT: level transmitter - Device that sends an electronic signal proportional to liquid level. $M$: mass flow rate ($kg/s$) - Total mass flow rate. $M_g$: gas mass flow rate ($kg/s$) - Mass flow rate of gas. $M_o$: oil mass flow rate ($kg/s$) - Mass flow rate of oil. $M_w$: water mass flow rate ($kg/s$) - Mass flow rate of water. NFA: net free area - Area available for flow after accounting for internal obstructions. NIL: normal interface level ($m$) - Desired operating interface level. NLL: normal liquid level ($m$) - Desired operating liquid level. $P$: pressure ($N/m^2$ or $Pa$) - Absolute pressure. $P_w$: wetted perimeter ($m$) - Perimeter of the flow channel in contact with the fluid. $Q$: volumetric flow rate ($m^3/s$) - Total volumetric flow rate. $Q_g$: gas volumetric flow rate ($m^3/s$) - Volumetric flow rate of gas. $Q_o$: oil volumetric flow rate ($m^3/s$) - Volumetric flow rate of oil. $Q_w$: water volumetric flow rate ($m^3/s$) - Volumetric flow rate of water. $Re$: Reynolds number (dimensionless) - Ratio of inertial forces to viscous forces, $Re = \rho V D / \mu$. $Re_f$: liquid film Reynolds number (dimensionless) - Reynolds number specifically for liquid film flow in mist eliminators. RVP: Reid vapor pressure ($bar$) - A measure of the volatility of gasoline and other petroleum products. $T$: temperature ($^\circ C$) - Operating temperature. TAN: vessel tangent line - The line where the cylindrical shell meets the head. TOV: top of vessel - The highest point of the vessel shell. TT: tangent to tangent - Length between the two tangent lines of a horizontal vessel. TVP: true vapor pressure ($bara$) - The actual vapor pressure of a liquid at a given temperature. USG: U.S. gallon - Unit of volume. VB: vortex breaker - Device placed at liquid outlets to prevent vortex formation. $V_B$: bulk liquid axial velocity ($m/s$) - Average velocity of the liquid phase along the vessel axis. $V_g$: gas velocity ($m/s$) - Velocity of the gas phase. $V_{g,h}$: horizontal vessel gas space velocity ($m/s$) - Gas velocity in the gas space of a horizontal vessel. $V_{g,v}$: vertical vessel gas space velocity ($m/s$) - Gas velocity in the gas space of a vertical vessel. $V_l$: liquid nozzle velocity ($m/s$) - Velocity of liquid exiting a nozzle. $V_m$: mixture velocity ($m/s$) - Velocity of the combined fluid mixture. $V_T$: particle terminal velocity ($m/s$) - Constant velocity reached by a falling particle when drag equals gravitational force. $\alpha$: roll or pitch angle ($^\circ$) - Angle of inclination of the vessel due to motion (e.g., offshore platforms). $A_{hd}$: drainpipe liquid height above vessel liquid level ($m$) - Difference in liquid height due to pressure drop. $\Delta P$: total pressure drop across mist eliminator ($Pa$) - Pressure loss across the mist eliminator. $\Delta P_d$: drainage pressure drop of mist eliminator ($Pa$) - Pressure drop specifically for liquid drainage from the mist eliminator. $\theta$: gas outlet nozzle-mist eliminator angles ($^\circ$) - Angle of gas flow relative to the mist eliminator. $\mu_c$: dynamic viscosity of continuous phase ($kg/m/s$) - Viscosity of the surrounding fluid. $\mu_l$: dynamic viscosity of liquid phase ($kg/m/s$) - Viscosity of the liquid. $\rho_c$: density of continuous phase ($kg/m^3$) - Density of the surrounding fluid. $\rho_d$: density of dispersed droplet phase ($kg/m^3$) - Density of the droplets being separated. $\rho_g$: gas density ($kg/m^3$) - Density of the gas phase. $\rho_H$: density of heavy phase ($kg/m^3$) - Density of the heavier liquid phase (e.g., water). $\rho_l$: liquid density ($kg/m^3$) - Density of the liquid phase. $\rho_L$: density of light phase ($kg/m^3$) - Density of the lighter liquid phase (e.g., oil). $\rho_m$: mixture density ($kg/m^3$) - Density of the gas-liquid mixture. $\sigma$: interfacial tension ($N/m$) - Surface tension between two immiscible liquids or a liquid and gas. 3. Design Parameters and Considerations 3.1 Separation Requirements The required separation efficiency is paramount and dictates the complexity and size of the separator. Overspecification leads to higher capital and operating costs, while underspecification can cause downstream equipment issues or product quality problems. Design Basis: Always design to meet specific downstream equipment requirements or product specifications. Bulk Separation: This is the primary function of most production separators. It involves removing the majority of one phase from another. Gas leaving production separator: A liquid carryover of $0.1\%$ to $1.0\%$ by volume may be acceptable if downstream equipment (e.g., coalescers, scrubbers for gas compressors, glycol dehydration units) can handle it. This implies that the gas is not yet pipeline quality or directly entering sensitive equipment. Oil in water: For bulk separation, residual oil in produced water of $\sim 5000$ mg/L (parts per million by weight) might be acceptable if further treatment is planned (e.g., CPI, DAF, hydrocyclones). Water in oil: Up to $\sim 15\%$ water in crude oil may be acceptable from a primary separator, depending on downstream processing (e.g., desalters, electrostatic treaters). High Efficiency Separation: Required for critical applications where even small amounts of carryover can cause significant problems. Example: Scrubbers upstream of glycol dehydration units or gas compressors. Liquid carryover here can lead to foaming in contactors, hydrate formation, or damage to compressor blades. Example: Separators providing feed to crude oil desalters, where low water content is crucial. Quantitative Specifications: Specifications must be clear and quantifiable. Absolute entrainment: e.g., $ Droplet cutoff criteria: Often specified by compressor manufacturers, e.g., "remove $99\%$ of all droplets $>\text{10 } \mu m$." This defines the minimum droplet size that must be removed. Removal efficiency: e.g., "$99.9\%$ liquid removal from gas." This is a percentage-based efficiency. Liquid control volumes: e.g., "provide 5 minutes of surge volume between NLL and LSH for downstream pump trip." This relates to the dynamic capacity of the liquid section. Avoid Overspecification: Specifying overly stringent separation requirements (e.g., $99.99\%$ removal of $3 \mu m$ droplets) can lead to significantly larger vessels, more complex internals, higher pressure drops, and increased costs without a justifiable process benefit. Specifications should be consistent with the capabilities of available internals technology and the actual needs of the downstream process. 3.2 Process Design Cases Separators must be designed to operate effectively across the entire range of anticipated process conditions, not just a single "normal" case. Operating Envelope: Evaluate all relevant operating scenarios. Design Flow Rate: The maximum expected flow rate, typically used for sizing the vessel and internals. This often includes a margin above normal operating flow. Normal Operating Flow Rate: The typical, steady-state flow conditions. Used for establishing normal operating levels and performance checks. Minimum Flow Rate: The lowest expected flow rate. Important for checking turndown capabilities, ensuring stable level control, and preventing issues like foaming or poor liquid-liquid separation due to insufficient velocity or turbulence. Transient Conditions: Start-up, shutdown, slugging from upstream, sudden changes in composition, or emergency depressurization. These can impose severe loads and off-design conditions. Fluid Property Variations: The design must account for variations in fluid properties over the life of the field or process. Liquid density: Changes due to temperature, pressure, or composition (e.g., increasing water cut). Watercut: The percentage of water in the total liquid phase, often increasing over field life. GVF (Gas Volume Fraction): Can vary significantly, impacting gas and liquid handling capacities. Fluid properties: Viscosity, interfacial tension, and foaming tendencies can change with time and operating conditions. Design Margins: While flow rates and fluid properties should include margins to cover uncertainties and future variations, the sizing criteria (e.g., K-factor values, droplet sizes) themselves should be based on established engineering principles and data without adding arbitrary margins. 3.3 Fluid Properties Accurate fluid property data is critical for accurate sizing and design. Required Data: Provide comprehensive data for all phases at relevant operating conditions: Densities ($\rho$): For gas, oil, and water. Essential for gravity separation and momentum calculations. Viscosities ($\mu$): For gas, oil, and water. Crucial for droplet settling/rising velocities and pressure drop calculations. Interfacial Tensions ($\sigma$): Between gas-liquid, oil-water, and gas-oil. Directly affects droplet formation, coalescence, and separation efficiency. Foaming and Emulsion Tendency: Foaming: Presence of stable gas bubbles in liquid. Can significantly reduce gas-liquid disengagement capacity and lead to carryover. Requires larger gas space or anti-foam measures. Emulsions: Stable dispersion of one immiscible liquid in another (e.g., water-in-oil or oil-in-water). Can hinder liquid-liquid separation. Requires longer residence times, higher temperatures, or deemulsifiers. Sensitivity Analysis: Conduct sensitivity analyses on key properties, especially interfacial tension and liquid viscosity, as these can vary significantly and have a large impact on separation performance. Small changes in IFT can drastically alter droplet sizes. 3.4 Separator Orientation Selection The choice between horizontal and vertical orientation depends on several factors, as summarized in Annex A (to be detailed below). 3.5 Mist Eliminator Selection The performance characteristics of different mist eliminator types (knitted mesh, vane pack, axial flow cyclone) are crucial for selecting the appropriate device. Annex B will provide more detail (to be detailed below). 3.6 Motion Effects For offshore floating production facilities (FPSOs, FLNGs), vessel motion (roll, pitch, heave) introduces significant challenges. Annex C will detail specific design considerations (to be detailed below). 3.7 Configurations Typical configurations and sizing examples are provided in Annex D and E (to be detailed below). 3.8 Process Sizing Data Requirements Input data should be provided in a standardized datasheet format (Annex F, to be detailed below) to ensure all necessary information is captured. 3.9 Inlet Piping The design of the inlet piping and its connection to the separator plays a critical role in overall performance. Poor inlet design can lead to maldistribution, excessive turbulence, and droplet shattering. Recommendations for configurations and lengths are in Annex G (to be detailed below). 4. Separator Sizing Specifications 4.1 General Specifications This section provides the fundamental principles and criteria for sizing two-phase and three-phase separators, including horizontal and vertical configurations. Design Categories: Separator design is typically broken down into distinct functional zones: Nozzles: Inlet, gas outlet, liquid outlet, and solids outlet. These must be sized to handle flow rates without excessive velocity, pressure drop, or entrainment. Liquid Gravity Settling Section: Where bulk liquid-liquid separation (in three-phase) or liquid-solid separation occurs, and where residence time for level control and degassing is provided. Gas Gravity Settling Section: The space above the liquid level where larger liquid droplets fall out of the gas phase due to gravity. Gas Demisting: Utilizes specialized internals to remove fine liquid droplets from the gas stream, ensuring gas purity. Performance Objectives: The separator design must ensure safe control and operation, meeting specific output quality targets: Liquid in gas specifications: (e.g., max liquid carryover, droplet size cutoff). Gas in liquid specifications: (e.g., max dissolved/entrained gas, minimum degassing time). Hydrocarbon liquid in water specifications: (e.g., max oil content in produced water). Water in hydrocarbon liquid specifications: (e.g., max water content in crude oil). Inlet Nozzle/Devices: Designed to: Mitigate droplet shatter and foam generation upon entry. Promote initial bulk separation of liquid and gas. Distribute the incoming flow to maximize the efficiency of the subsequent separation sections. Outlet Nozzles: Designed to: Effectively remove the desired phase (gas, oil, water). Minimize entrainment of other phases. Liquid Gravity Section: Provides: Sufficient volume for level control and surge capacity. Time for degassing and defoaming of the liquid phase. Space for solids settling (if applicable). Capacity to handle slug flows from upstream. Meet downstream equipment requirements for liquid quality. Gas Gravity Section: Reduces the overall liquid load on the final gas demisting section by removing larger droplets. Gas Demisting Section: Ensures the final gas stream meets purity specifications by removing fine liquid aerosols. Sizing Criteria - K-factor (Souders-Brown Equation): This empirical relationship is widely used for preliminary sizing of the gas-liquid disengagement area. It relates the maximum allowable gas velocity to the densities of the gas and liquid phases. $$V_g = K \sqrt{\frac{\rho_l - \rho_g}{\rho_g}}$$ Where: $V_g$: Maximum allowable gas velocity ($m/s$) $K$: Souders-Brown K-factor ($m/s$), an empirical coefficient determined by experience, operating pressure, and type of demisting device. $\rho_l$: Density of the liquid phase ($kg/m^3$) $\rho_g$: Density of the gas phase ($kg/m^3$) The K-factor accounts for the efficiency of liquid droplet removal. Higher K-factors allow higher gas velocities, leading to smaller vessel diameters for a given gas flow rate. However, selecting an appropriate K-factor is crucial; too high a value can lead to excessive liquid carryover, while too low a value results in an oversized and costly vessel. 4.2 Nozzles 4.2.1 Inlet Nozzle/Inlet Devices The inlet section is critical for initial separation and flow distribution. Poor design here can lead to re-entrainment, foaming, and reduced separation efficiency throughout the vessel. Sizing: The inlet nozzle must be sized in conjunction with the chosen inlet device. The primary functions are to provide bulk liquid separation, separate large drops/bubbles, distribute flow, and prevent droplet shatter or foaming. Internal Diameter ($D_{in}$): The inlet nozzle ID should be at least equal to the inlet pipe ID ($D_p$). If a larger nozzle is used, the upstream piping should expand gradually over a length of at least 10 pipe diameters to minimize turbulence and pressure drop. Inlet Devices Sizing: Inlet devices are sized based on the momentum flux of the incoming stream, which is a measure of the kinetic energy of the fluid. Momentum Flux: $\rho_m V_m^2$, where: $V_m$: Mixture velocity ($m/s$) in the inlet nozzle, calculated as $V_m = \frac{Q_o + Q_w + Q_g}{A_N}$. $\rho_m$: Mixture density ($kg/m^3$), calculated as $\rho_m = \frac{M_o + M_w + M_g}{Q_o + Q_w + Q_g}$. Typical Inlet Devices and Their Limits: Half-Open Pipe: Simple, low cost. Momentum flux limit: $3000-5000 \text{ kg/(m} \cdot s^2)$. Liquid velocity limit: $3-5 \text{ m/s}$. Best for low momentum fluxes. Deflector Baffle (Impact Plate): Directs flow against a plate, dissipating momentum. Momentum flux limit: $5000-10000 \text{ kg/(m} \cdot s^2)$. Can generate turbulence and foam if not designed carefully. Inlet Vane Diffuser (IVD): Uses vanes to impart a swirling motion to the incoming fluid, promoting centrifugal separation. Momentum flux limit: $10000-20000 \text{ kg/(m} \cdot s^2)$. Highly efficient. Cyclonic Inlets: Induce strong centrifugal forces for efficient bulk separation. Momentum flux limit: $15000-30000 \text{ kg/(m} \cdot s^2)$ or higher. Requires careful design to prevent liquid carry-under or gas blow-through. Table 1: Maximum Inlet Momentum Flux and Velocity Limits (Illustrative - actual values vary by vendor and specific design) Inlet Device Type Max Momentum Flux ($\text{kg/(m} \cdot s^2)$) Max Inlet Velocity (m/s) Comments Half-Open Pipe 3000 - 5000 3 - 5 Simple, low cost, for low momentum. Deflector Baffle 5000 - 10000 5 - 8 Momentum dissipation by impact. Inlet Vane Diffuser (IVD) 10000 - 20000 8 - 15 Induces swirl, good bulk separation. Cyclonic Inlet 15000 - 30000+ 10 - 25+ High efficiency, compact, higher pressure drop. Inlet Cyclones: Require careful adjustment of liquid levels to prevent liquid carry-under (gas pulled into liquid outlet) or gas blow-through (liquid pulled into gas outlet). Horizontal Vessels: Distribution baffles are often used with inlet devices to promote plug flow and minimize turbulence in the liquid section. 4.2.2 Gas Outlet Nozzle Sizing: The gas outlet nozzle sizing is dependent on the type of demisting technology used and the allowable pressure drop across the outlet system. Flow Distribution: The nozzle design must not negatively impact the gas/liquid distribution to the demisting device (if present) or cause re-entrainment of liquid from the mist eliminator. Table 2: Maximum Gas Outlet Nozzle Momentum Flux and Velocity Limits (Illustrative) Parameter Value Comments Max Momentum Flux ($\rho_g V_g^2$) 12000 - 15000 $\text{kg/(m} \cdot s^2)$ To avoid excessive pressure drop and noise. Max Gas Velocity ($V_g$) 30 - 40 m/s Lower for critical applications or higher density gas. Outlet Piping: The piping immediately downstream of the gas outlet nozzle should ideally match the nozzle diameter for at least 3 to 5 pipe diameters to ensure smooth flow and prevent pressure recovery issues that could cause re-entrainment. 4.2.3 Liquid Outlet Nozzles Design Principle: Liquid outlets are designed to remove the separated liquid phase without disturbing the gravity settling section or entraining other phases. Vortex Breakers (VBs): Most liquid outlets are fitted with VBs to prevent the formation of a vortex, which can entrain gas into the liquid outlet or lighter liquid into the heavier liquid outlet. VBs are typically cross-shaped plates extending out from the nozzle. Elevated Outlets: In some cases, liquid outlets may be elevated to accommodate solids accumulation at the bottom of the vessel, preventing the nozzle from becoming blocked. Sizing Criteria: Two-phase Separators (gas-liquid): For hydrocarbon or mixed-phase liquid outlets, the maximum velocity is typically limited to $2 \text{ m/s}$ to minimize erosion and prevent cavitation if connected to a pump. Three-phase Separators (gas-oil-water): Hydrocarbon (oil) nozzle: Maximum velocity typically $2 \text{ m/s}$. Water nozzle: Maximum velocity typically $1 \text{ m/s}$. Lower velocity for water is often specified to minimize oil entrainment into the water and reduce erosion from any suspended solids. Feed to Pump Suction: If the liquid outlet feeds directly to a pump suction, the velocity is often further limited to $1 \text{ m/s}$ to ensure adequate NPSH (Net Positive Suction Head) and prevent cavitation. Critical Separation Services: For services requiring very low entrainment (e.g., glycol-rich feed to reboiler), liquid outlet nozzles should be designed for self-venting flow (to prevent vapor lock or two-phase flow in the outlet line). Details in Annex I. Large Nozzles: For liquid outlet nozzles with ID $>24 \text{ in.}$ (approx. DN600), additional submergence criteria may apply for LSL/LISL to ensure adequate liquid head and prevent gas ingress. Solids Removal Systems: Liquid outlets, especially in vessels designed for solids, must be configured to facilitate solids removal (e.g., flush connections, sloped bottoms). 4.2.4 Solids (Sand) Outlet Nozzles Minimum ID: A minimum ID of DN50 (2 inches) is typically specified to prevent blockage by sand and other solids. Larger sizes (e.g., DN100) are common for high solids content. Internals: If the vessel is fitted with internals, care must be taken to ensure they do not create stagnant zones where solids can accumulate and block flow paths to the outlet. Exit Velocity: The exit velocity from the solids outlet is typically limited to $3 \text{ m/s}$ to minimize erosion of the nozzle and downstream piping. Higher velocities can be used if erosion-resistant materials are employed. 4.3 Liquid Gravity Settling Section This section of the separator is crucial for providing sufficient residence time for phase separation and for stable level control. 4.3.1 General Principles Primary Function: Allows for the gravity-driven separation of larger liquid drops from gas, gas bubbles from liquid, and (in three-phase separators) oil from water or water from oil. It also provides volume for solids to settle. Minimum Requirements: The liquid section must provide: Level Control/Reaction Time: Sufficient volume between alarm and trip levels to allow control systems and operators to respond to flow variations. Degassing and Defoaming: Time for entrained gas bubbles to rise and disengage from the liquid phase. Solids Settling: If solids are present, adequate residence time and low velocities for them to settle out. Three-phase Separators (additional considerations): Velocity Limits: Bulk liquid velocities must be kept low to minimize turbulence that could hinder oil-water separation. Water Droplets Settling out of Oil: The oil phase must provide sufficient length and time for dispersed water droplets to settle. Oil Droplets Settling out of Water: Similarly, the water phase must allow dispersed oil droplets to rise and separate. Liquid Level and Inlet Devices: The liquid levels (NLL, NIL) are often adjusted based on the type of inlet device. For example, some inlet devices operate best when submerged to promote liquid-liquid separation, while others may be left unsubmerged to prevent re-entrainment of gas. Foaming Risk: An excessive distance between the inlet device and the liquid level can increase the risk of foaming as the incoming fluid splashes. Sizing Driver: The largest of the various requirements (level control, degassing, liquid-liquid separation, solids settling) will dictate the overall size of the liquid section. 4.3.2 Level Control/Reaction Times The volumes between various level settings (NLL, LAH, LSH, LAL, LSL) provide the necessary buffer for stable operation and safe shutdown. Buffer Volume: The volume of liquid contained between successive level settings provides a specific amount of time for operators or automated control systems to react to changes in liquid flow or level. Table 3: Minimum Liquid Levels and Control Times (Illustrative - subject to company standards) Level Point Description Minimum Control Time (min) Typical Vertical Spacing (mm) LSL Low Liquid Level Trip N/A (safety trip) 100-150 below NLL LAL Low Liquid Level Alarm 2-5 min 150-200 below NLL NLL Normal Liquid Level N/A (operating point) Reference point LAH High Liquid Level Alarm 2-5 min 150-200 above NLL LSH High Liquid Level Trip N/A (safety trip) 100-150 above NLL Note: For three-phase separators, similar levels apply to the interface (NIL, LIAL, LISH, etc.). Motion Effects: For vessels on floating facilities, motion (roll, pitch) can cause significant level fluctuations. Annex C provides specific guidance to account for these effects, often requiring larger level spans. Safety Shutdowns: Safety Instrumented Systems (SIS) require independent instrumentation for LSH and LSL (and LISH/LISL) from the normal operating level control (LT, LAH, LAL) to ensure integrity and prevent common cause failures. Calculation of Surge Volume: The volume ($V_{surge}$) between two levels ($h_1$ and $h_2$) can be calculated from vessel geometry. For a horizontal cylindrical vessel, this involves integrating the area of a segment. For a vertical vessel, it's simply $A_{g,v} \times (h_2 - h_1)$. The time ($t_{surge}$) is $V_{surge} / Q_l$, where $Q_l$ is the maximum liquid flow rate. 4.3.3 Degassing and Foaming Entrained gas in the liquid phase can lead to cavitation in downstream pumps, inaccurate level readings, and reduced product quality. Foaming exacerbates these issues. Degassing Criteria: The liquid section must be sized to allow entrained gas bubbles to rise and disengage. Critical Applications: For very critical services (e.g., pump suction, glycol feed), the liquid section is sized to allow a $200 \mu m$ gas bubble to rise from the bottom of the vessel (or from the interface in a three-phase separator) to the NLL (or NIL) within the liquid residence time. This is a conservative criterion. Less Critical Applications: For less critical services, a larger bubble size (e.g., $600 \mu m$) may be acceptable. Bubble Rise Velocity ($V_{bubble}$): Calculated using a modified Stokes' Law, accounting for hindered settling if gas holdup is significant. $$V_{bubble} = \frac{g d_b^2 (\rho_l - \rho_g)}{18 \mu_l}$$ Where $d_b$ is the bubble diameter. Horizontal Vessels: Effective gas bubble disengagement lengths are used (refer to Figures 3, 4, which would be diagrams illustrating liquid flow paths and residence times in horizontal vessels, showing how the gas bubbles rise out of the liquid phase). Vertical Vessels: The criterion is that the bubble rise velocity must exceed the downward bulk liquid velocity to ensure bubbles move upwards and disengage. $V_{bubble} > V_{liquid,downward}$. Foamy Systems: Foam is a dispersion of gas in liquid where the gas phase is continuous, stabilized by surface-active agents. Foaming significantly reduces separation efficiency and gas capacity. Impact: Foam can fill the gas space, leading to liquid carryover into the gas outlet and gas carry-under into the liquid outlet. It also makes level control difficult. Mitigation: Increase the spacing between LAH and LSH by $\geq 250 \text{ mm}$ (or more) to accommodate the foam layer. Employ anti-foam chemicals. Install mechanical foam breakers (e.g., deflectors, mesh pads, or specialized internals designed to rupture bubbles). Inlet Device Impact: The choice and design of the inlet device significantly impact the amount of dispersed gas and foam generation. High momentum inlets can create more foam. 4.3.4 Solids Removal Solids (e.g., sand, scale, corrosion products) can accumulate in separators, reducing liquid volume, blocking internals, and causing erosion. Design for solids handling is crucial for systems with solids production. Horizontal Production Separators: Often preferred for solids removal due to their larger bottom area for collection and easier access for flushing/draining. Vessel Sizing: The vessel must be sized to accommodate a specified volume of collected solids without impacting normal operation. This includes space for: Settled Solids Volume: Based on expected solids production rate and cleaning frequency. Handling Infrastructure: Space for water jetting systems, sand dams, sluice pipes, and solids outlet nozzles. Vertical Separators: If solids are expected in vertical separators, consider: Accumulation: Ensuring liquid outlets are not at the absolute bottom or that stagnant sections are avoided to prevent solids buildup. Cone Bottoms: Often used to facilitate solids collection and removal. Solids Settling Velocity ($V_s$): Calculated using Stokes' Law for small particles or more complex correlations for larger particles (e.g., intermediate or Newton's Law regimes). $$V_s = \frac{g d_p^2 (\rho_p - \rho_l)}{18 \mu_l}$$ Where $d_p$ is particle diameter and $\rho_p$ is particle density. The vessel's liquid residence time must be sufficient for particles to settle. 4.4 Gas Gravity Section This section primarily removes larger liquid droplets from the gas phase via gravity settling before the gas reaches the final demisting section. Function: Allows liquid droplets that are too large to be carried by the gas (due to their weight) to fall out of the gas stream and coalesce with the bulk liquid. This reduces the load on the mist eliminator. Sizing Criteria: The required gas space area is typically determined by two primary considerations: K-factor: The maximum allowable gas velocity ($V_g$) is calculated using the Souders-Brown equation (see Section 4.1). The K-factor selected for the gas gravity section is generally lower than that for the mist eliminator, as it relies solely on gravity. Table 5: Illustrative K-factors for Horizontal Gas Gravity Section Pressure (bara) K-factor (m/s) 0.06 - 0.09 10 - 20 0.09 - 0.12 > 20 0.12 - 0.15 Table 6: Illustrative K-factors for Vertical Gas Gravity Section Pressure (bara) K-factor (m/s) 0.08 - 0.11 10 - 20 0.11 - 0.14 > 20 0.14 - 0.18 Note: These K-factors are for the bulk gas space, not for mist eliminators. Specific K-factors depend on fluid properties, droplet size, and operational experience. Interface Entrainment: The gas velocity must be limited to prevent re-entrainment of liquid droplets from the gas-liquid interface. High gas velocities can cause "shearing" of the liquid surface, creating new droplets. Annex J provides more details on this phenomenon. Fluid Properties: When dealing with light and heavy liquids (e.g., oil and water), the physical properties of the lighter liquid (oil) are typically used for gas gravity section calculations, as it is the phase most likely to be entrained into the gas. 4.5 Gas Demisting Section The final stage of gas processing, designed to remove fine liquid droplets that did not settle in the gas gravity section. 4.5.1 General Principles Function: Removes very small liquid droplets (mist) from the gas stream, ensuring the gas meets downstream purity specifications. These droplets are too small to be effectively removed by gravity alone. Droplet Size Range: Figure B.1 (to be detailed below in Annex B) illustrates the typical droplet size ranges handled by different mist eliminator technologies. Generally, these range from $1 \mu m$ to $500 \mu m$. 4.5.2 Gas Demisting Technology The selection of the appropriate mist eliminator depends on factors like gas capacity, liquid loading, fluid properties, and the required droplet cutoff size. Table 4: Relative Performance Characteristics of Mist Eliminators Characteristic Wire Mesh Pad Vane Pack Axial Flow Cyclone Efficiency (small drops) High ($>5 \mu m$) Medium ($>8 \mu m$) High ($>3 \mu m$) Liquid Loading Low-Medium Medium-High High Turndown Ratio Low (2:1 to 3:1) Medium (3:1 to 5:1) High (up to 10:1) Pressure Drop Low Medium High Fouling Resistance Low Medium-High High Cost (relative) Low Medium High Space Requirement Medium Low Low (compact) Solids Handling Poor Good Excellent 4.5.3 Gas Demisting Sizing K-factor Application: If a mist eliminator is required, its sizing will also use a K-factor, but these K-factors are generally higher than those for the gas gravity section, reflecting the enhanced separation capabilities. Refer to Tables 5 and 6 for typical K-factors for various mist eliminator types (these would be separate tables from the gravity K-factors, or specific K-factors would be given for each mist eliminator type). Example K-factors for Mist Eliminators (Illustrative): Mesh Pad: $0.10 - 0.15 \text{ m/s}$ (depending on density, pressure, mesh type) Vane Pack: $0.15 - 0.25 \text{ m/s}$ Axial Flow Cyclone: $0.25 - 0.40 \text{ m/s}$ Pre-separation: Sufficient gravity separation upstream of the mist eliminator is crucial to prevent it from flooding. If the liquid load on the mist eliminator is too high, it will become inefficient and lead to excessive carryover. Evaluation: Design must consider expected entrainment rates, target droplet size cutoff, and maximum liquid loading conditions. Mist Eliminator Drainage: Liquid collected by the mist eliminator must be drained effectively back into the bulk liquid phase. Drainage pipes must be sealed in the liquid phase (submerged) to prevent gas bypass and ensure continuous liquid flow. The pipe outlet should be below the LSL and above any potential solids accumulation level (e.g., $100 \text{ mm}$ above the solids level). Drainage pipes should be designed to be self-venting (Annex I) to avoid vapor lock. Drainage Pressure Drop ($\Delta P_d$): The pressure drop required to push the collected liquid down the drain pipe. This pressure drop causes the liquid level inside the drain pipe to be higher than the bulk liquid level in the vessel. $$\Delta h_d = \frac{\Delta P_d}{(\rho_L - \rho_g)g}$$ Where $\Delta h_d$ is the drainage height difference. Minimum Spacing: The vertical distance between the LSH and the bottom of the mist eliminator must be sufficient to accommodate this drainage height difference, ensuring the mist eliminator does not become submerged in liquid during high liquid level conditions. A common rule of thumb is that the maximum calculated liquid level in the drainage pipe must be $ 4.6 Horizontal Two-phase and Three-phase Separator Specifications (Additions) Horizontal separators are characterized by a large liquid-gas interface, making them suitable for high liquid volumes and three-phase separation. 4.6.1 Inlet Nozzle/Inlet Devices Location: Inlet nozzles can be through the vessel head or the cylindrical shell. Placing them through the head is often preferred as it minimizes structural complications on the shell. LSH Spacing: The spacing between the LSH and a non-submerged inlet device is critical to prevent liquid carryover into the inlet section during high liquid levels. Figures 3 and 4 (conceptual diagrams) would illustrate this, showing typical distances required. Distribution Baffles: Purpose: Used downstream of the inlet device to smooth the velocity profile, ensure even flow distribution across the vessel cross-section, and promote plug flow in the liquid section. They also help to dampen waves. Boundary Definition: They define the boundary between the inlet section (where initial momentum dissipation occurs) and the gravity separation sections (gas and liquid). Types: Can be perforated plates, slats, louvers, or even structured packing (though packing is generally avoided for viscous or dirty fluids due to fouling). Open Area: Typically $20\%-40\%$ open area to provide sufficient flow while distributing. Liquid Level Impact: Design must consider how baffles affect liquid levels and potential for liquid holdup. Fouling/Plugging: For services with potential for fouling or solids, larger holes or slat spacing (e.g., $25-75 \text{ mm}$ hole diameter; $50-75 \text{ mm}$ for severe fouling) are recommended. Robustness: Baffles must be mechanically robust to withstand forces from slugs, surges, and vessel motion (if applicable). CFD: Computational Fluid Dynamics (CFD) is often used to optimize baffle design, predict flow patterns, and ensure uniform distribution in complex scenarios. 4.6.2 Gas Outlet Nozzle Design: The vapor outlet is typically located at the top of the vessel. Figure 5 (conceptual diagram) would show the typical arrangement, including spacing from the mist eliminator. Spacing: Smaller spacings between the mist eliminator and the gas outlet nozzle may be allowed for mist eliminators that generate a higher pressure drop (e.g., cyclones), as the higher velocity helps prevent re-entrainment. 4.6.3 Liquid Outlet Nozzles Location: In horizontal vessels, liquid outlet(s) are typically located at the bottom of the vessel, usually at the end opposite to the inlet to maximize the liquid settling path. 4.6.4 Liquid Gravity Section (Additional for Three-phase) In three-phase separators, the liquid section is split into distinct oil and water phases, with an interface between them. Objective: The oil and water sections must be sized to achieve the specified residual water in oil and oil in water specifications. Key Criteria: Maximum Bulk Liquid Axial Velocity ($V_B$): This is the average horizontal velocity of the liquid phase below the NLL. It is crucial to limit this velocity to prevent re-entrainment of dispersed droplets and to allow sufficient time for settling. Typically limited to $0.015 - 0.030 \text{ m/s}$. Lower values (e.g., $0.015 \text{ m/s}$) are used for heavy/viscous oils, tight emulsions, or critical separation requirements. Higher values (e.g., $0.030 \text{ m/s}$) may be acceptable for less critical applications with easily separable fluids. Droplet Removal Criteria: Water from oil: For high free water removal (e.g., aiming for $ For bulk separators with a few percent water (e.g., $2-5\%$ water in oil), removal of $350-500 \mu m$ water droplets is often sufficient. For higher residual water content (e.g., $10-15\%$ water in oil), removal of $1500 \mu m$ droplets might be the design basis. Oil from water: For produced water treatment, aiming for removal of $150 \mu m$ oil droplets is a common design target. More stringent requirements (e.g., $50 \mu m$) may necessitate specialized equipment. Droplet Settling/Rising Models (Annex H - to be detailed): Stokes' Law: For small droplets ($Re_d Intermediate Law: For $0.2 Newton's Law: For larger droplets ($Re_d > 500$), where inertial forces dominate. $$V_T = \sqrt{\frac{4 g d_p (\rho_p - \rho_c)}{3 C_D \rho_c}}$$ Where $C_D$ is the drag coefficient, typically $0.44$ for spheres. The effective separation length ($L_{eff}$) required for a droplet to settle or rise is given by $L_{eff} = H_{separation} \times (V_B / V_T)$, where $H_{separation}$ is the vertical distance the droplet must travel. The actual vessel length must be greater than this $L_{eff}$. Effective Separation Lengths: If distribution baffles are installed, the effective length starts from the baffle. Otherwise, it's typically taken as 1 vessel diameter downstream from the inlet device or the tangent line/nozzle centerline. Plate Packs: Can be used to enhance liquid-liquid separation by providing a larger surface area for coalescence and reducing the settling distance. However, they are prone to fouling and plugging in dirty services. CFD: For complex flow patterns, revamps, or critical services, CFD modeling can provide detailed insights into fluid behavior, optimize internal placement, and predict separation performance. Solids Removal: In addition to liquid-liquid separation, the liquid section must also be sized for the settling of solids. The particle size chosen for settling calculations will be an additional criterion, typically based on the smallest particle size that must be removed. Settling Lengths: Figures 3, 4 (conceptual diagrams) would show how settling lengths are defined in horizontal vessels for oil-water separation. Two-phase Separator: For solids settling, particles settle from the NLL to the BOV. The highest liquid viscosity and density are used for conservative calculations. Three-phase Separator: Particles settle from the NLL to the BOV, with considerations for the oil-water interface. 4.6.5 Gas Gravity Section (Additions for Horizontal) Gas Phase Flow Area: The cross-sectional area available for gas flow is the vessel area above the LAH (or LAH plus an allowance for foam height). Foamy Oils: If foaming is anticipated, specific internals (e.g., anti-foam vanes, mesh pads designed for foam breaking) may be installed in the gas space. These introduce additional pressure drop and require careful evaluation for fouling and plugging. Ballistic Model (Annex H - to be detailed): Can be used to estimate the maximum droplet size that can be carried from the TOV (top of vessel) by the gas stream, considering horizontal gas velocity and vertical settling velocity. 4.6.6 Weirs Weirs are commonly used in three-phase horizontal separators to separate the light liquid (oil) from the heavy liquid (water). Function: A weir creates a static barrier, allowing the lighter phase to flow over it while the heavier phase is retained below. Advantages over Elevated Outlets: Improved plug flow characteristics in the liquid phase. Reduced short-circuiting of fluids. Lower pressure drop compared to control valves on elevated nozzles. Reduced risk of funneling gas into the liquid outlet. Types: Flooded (Submerged) Weirs: The weir is completely submerged in the heavy liquid phase. The light phase flows over it. Often used when the entire vessel length is desired for light phase separation, or in floating facilities where motion can affect liquid levels. Overflow (Spillover) Weirs: The light liquid flows over the top edge of the weir. This maintains a constant oil level upstream of the weir. Hydraulics of Overflow Weirs: The liquid level upstream of an overflow weir will be the weir height plus a "crest" height, which depends on the liquid flow rate. The Francis weir equation (or similar) can be used to calculate this crest height: $$Q_l = C \cdot L_{weir} \cdot H_{crest}^{1.5}$$ Where $Q_l$ is liquid flow, $C$ is a coefficient, $L_{weir}$ is weir length, and $H_{crest}$ is the crest height. V-shaped Weirs: Can be used for better flow control, especially at low flow rates, as they maintain a more consistent crest depth over a wider range of flows. Weir Height: Weirs are typically designed to be $\geq 150 \text{ mm}$ higher than the highest expected oil-water interface level to prevent water carryover with the oil. Weir Support Design: It is good practice to design weir supports to allow for future installation of a higher weir (e.g., up to $60\%$ of the vessel diameter) to accommodate changes in fluid properties or operating conditions over the field's life. 4.6.7 Vessel Aspect Ratio ($L_{TT}/D$) The length-to-diameter ratio is a key design parameter for horizontal separators. Minimum Ratio: A minimum $L_{TT}/D$ of $2.5$ is generally recommended for good flow distribution and separation efficiency. Three-phase Separation: Higher ratios (e.g., $3$ to $5$) are often preferred for three-phase separators to provide adequate residence time for both oil-water and gas-liquid separation. Longer vessels provide more quiescent zones for gravity separation. Impact: A very low $L_{TT}/D$ can lead to short-circuiting, maldistribution, and reduced effective separation length. Very high $L_{TT}/D$ can lead to excessive pressure drop and higher fabrication costs. 4.7 Vertical Two-phase Separator Specifications (Additions) Vertical separators are typically used for high gas-liquid ratios, where liquid holdup is relatively small, or where plot space is limited. 4.7.1 Inlet Nozzle/Inlet Devices LSH Spacing: Similar to horizontal vessels, adequate spacing between the LSH and a non-submerged inlet device is needed to prevent liquid carryover into the inlet section during high liquid levels. Figures 6, 7, 8 (conceptual diagrams) would illustrate typical arrangements and spacing. 4.7.2 Gas Outlet Nozzle Location: The top vapor outlet is typically located in the center of the top head to ensure even flow distribution from the mist eliminator. Spacing: Spacing from the mist eliminator is critical for proper gas flow and liquid drainage. Figure 9 (conceptual diagram showing gas outlet relative to mist eliminator) illustrates this. Smaller Spacings: For mist eliminators with higher pressure drops (e.g., cyclones), smaller spacings may be acceptable due to the higher gas velocities promoting rapid liquid disengagement. Outlet Line Projection: The vapor outlet line often projects into the vessel to the edge of the mist eliminator at an angle of $\geq 45^\circ$ to minimize turbulence and improve flow into the nozzle. 4.7.3 Liquid Outlet Nozzles Location: The bottom liquid outlet is preferably located in the center of the bottom head to facilitate complete drainage and minimize stagnant zones. Drain: A separate drain connection is typically provided at the absolute bottom for complete liquid removal during maintenance. Submergence: Submergence requirements for the liquid outlet are similar to horizontal vessels (refer to Table 3) to prevent gas ingress. 4.7.4 Gas Gravity Section (Additions for Vertical) Gas Phase Flow Area: For vertical vessels, the entire cross-sectional area of the vessel is considered the gas space for bulk separation ($A_{g,v}$). Maximum Allowable K-factor: The maximum allowable K-factor for the vessel's gas space is applied to determine the minimum required diameter for the gas flow. Refer to Table 6 (specific to vertical vessels). Interface Entrainment: If the design methods are followed and gas velocities are within limits, re-entrainment of droplets from the gas-liquid interface is generally not a significant issue in vertical vessels due to the relatively lower horizontal velocity components. 4.7.5 Gas Demisting Section (Additions for Vertical) Mist Eliminator Orientation: Table 6 (conceptual, detailing suitable mist eliminator orientations for vertical vessels) would provide guidance on preferred orientations (e.g., horizontal for mesh pads, vertical for vane packs). Typical Scrubbers: Single Mist Eliminator (Figure 6): Standard configuration, simple and cost-effective. Dual Mist Eliminators (Figure 7): Used for higher turndown ratios, improved efficiency, or for handling higher liquid loads. The first element acts as a coarse separator, the second as a fine polisher. Horizontal Flowing Vane Mist Eliminator (Figure 8): While less common in vertical vessels, these can be used but are mechanically more complex. LSH Spacing and Drainage: The spacing between the LSH and the bottom of the mist eliminator is critical for proper drainage of collected liquid and to prevent flooding of the mist eliminator. This spacing follows the same drainage pressure drop principles as discussed in Section 4.5.3. 4.7.6 Vessel Aspect Ratio ($L_{TT}/D$) For vertical separators, the vessel height-to-diameter ratio depends on the specific design requirements (e.g., liquid holdup, gas space, number of internals). There isn't a strict universal minimum like for horizontal vessels, but practical considerations for stability and cost usually dictate the range. 5. Instrumentation Proper instrumentation is vital for safe operation, control, monitoring, and troubleshooting of separators. 5.1 General Principles Purpose: Separators require pressure, temperature, and level instruments for effective process control and for identifying operational issues. Safeguarding: Safety Instrumented Systems (SIS) instrumentation must comply with standards like API 14C [12] for safety shutdowns and alarms. This ensures the vessel operates within its safe operating limits. "Sensor" Definition: The term "sensor" encompasses both basic indicators (e.g., pressure gauges, sight glasses) and electronic sensors (e.g., transmitters feeding to a DCS or ESD system). Instrument Connections: Designed to allow removal and installation of instruments without requiring a process shutdown (e.g., using block valves and bypasses). Nozzles and tubing must be configured for flushing to prevent plugging by solids or viscous fluids. Connections should be free-draining to prevent liquid holdup, which could lead to freezing or hydrate formation. Independence: Separate nozzles are typically required for process control instruments and safety system instruments to ensure independence and prevent common cause failures. Solids Accumulation: In services with solids, instrument nozzles in the lower part of the vessel should be located on the side, not directly at the bottom, to minimize blockage. Environmental Protection: Insulation and heat tracing are essential for instrument nozzles and impulse lines in cold environments to prevent hydrate formation, wax precipitation, or freezing of process fluids. Motion Effects: For offshore facilities, the placement of sensors must account for vessel motion (Annex C). For example, level instrument ranges may need to be expanded, and probes may require baffling to prevent false readings due to sloshing. Accuracy: The accuracy of each instrument must be specified based on the application's control requirements. 5.2 Pressure Sensors Location: Use nozzles not directly in the path of high-velocity flows to avoid dynamic pressure effects. Avoid locations affected by fluid velocity; if unavoidable, shielding (e.g., stilling wells) may be required. Choose locations that reduce the risk of blockage by solids, wax, or other contaminants. Impulse Lines: Insulation and heat tracing are critical for impulse lines connecting the vessel to remote pressure transmitters, especially in cold or hydrate-forming conditions. 5.3 Differential Pressure Sensors Application: Used to monitor pressure drop across internal devices such as baffles, packing, or mist eliminators. This helps detect fouling, flooding, or clogging. Requirements: All requirements for single-point pressure sensors (Section 6.2) apply to differential pressure sensors. 5.4 Fluid Sample Nozzles Quantity and Location: The number and location of sample nozzles (for gas, oil, water) are determined by company guidelines and process monitoring needs. They should be placed to obtain representative samples. 5.5 Level Sensors 5.5.1 General Central Inlet Separators: For separators with a central inlet and multiple separation zones, it may be necessary to have level instruments in both the upstream and downstream sections to monitor liquid distribution. Measurement Range: Sensors must be capable of measuring the entire required range, from LSL/LISL to LSH/LIAH, including any foam layers. Placement: Placed to avoid interference from other internals (e.g., baffles, inlet devices) and to ensure accurate readings. Flow Effects: Avoid locations affected by high fluid velocity or turbulence. Stilling wells or cages are often used for float-type instruments or displacers to dampen fluctuations. 5.5.2 Internal Level Sensors Preference: Internal sensing elements are often preferred as they provide a direct measurement inside the vessel without external piping, reducing leak points and maintenance. Measurement Capabilities: Can measure interface levels, identify fluid types, and sometimes detect solids accumulation. Technologies: Nucleonics (Gamma Ray): Non-contact, measures density profiles. Good for harsh conditions, foaming, emulsions. Radar (Guided Wave or Free Space): Measures distance to liquid surface/interface. Good for varying densities, high pressures/temperatures. Capacitance/Inductance: Measures changes in dielectric constant/conductivity. Good for interface detection. Thermal Energy Absorption/Diffusion: Detects changes in thermal conductivity. Can differentiate phases. Mechanical Floats: Simple, reliable, but can be affected by debris or high viscosity. Performance Evaluation: The performance of level profile meters (which read multiple levels) must be carefully evaluated for challenging conditions like heavy oil, tight emulsions, or severe foaming. Interface Level Sensors: Should use nozzles not carrying significant flow to avoid interference. Mechanical Robustness: Internal level sensors and profilers must be designed to withstand mechanical loading from fluid forces (e.g., slug impacts, sloshing in offshore applications). Shielding: Probes may require perforated pipe shielding to protect them from fluid mechanical loads. Vendor Consultation: Early consultation with sensor technology suppliers is recommended to select the most appropriate and robust solution. 5.5.3 External Mechanical and Visual Level Gauges External Mounting: If level measurement is performed externally, separate nozzles are typically required for each different density fluid phase (e.g., one for oil, one for water in a three-phase separator). Figure 11: (Conceptual diagram) would show typical externally mounted level indicators (e.g., sight glasses, magnetic level gauges) and transmitters (e.g., displacers, DP transmitters) with their associated nozzles and impulse lines. 5.6 Temperature Sensors Location: Sensors must be placed to remain in the fluid of interest under all operational conditions, including level fluctuations and sloshing. Located in the zone where temperature measurement is most critical (e.g., near a heater for control, or where phase changes occur). Avoid locations where solids or wax can accumulate and thermally insulate the probe, leading to inaccurate readings. Probes should be long enough to extend into the bulk fluid and avoid stagnant zones near the vessel wall. Thermowells: Temperature probes are almost always installed in thermowells (Figure 12 - conceptual diagram showing a thermowell installation) to allow for removal and maintenance without depressurizing or draining the vessel. Thermowells must be designed to withstand process conditions and flow-induced vibration. Avoid placing thermowells in high-velocity jets or areas prone to mechanical vibrations. 6. Mechanical Design Considerations The mechanical design ensures the vessel can safely contain the fluids and withstand all internal and external forces over its operational life. It is inextricably linked to the process design. 6.1 General Principles Pressure Vessel: A separator is almost always classified as a pressure vessel and must comply with relevant design codes (e.g., ASME Boiler and Pressure Vessel Code, EN 13445). Interrelation: Process design defines the operating envelope, fluid properties, flow rates, and internal component functions. Mechanical design translates these requirements into a physically robust structure. The process designer must be aware of the mechanical implications of their choices. Internal Components: All internals (baffles, inlet devices, mist eliminators, supports) must be designed to withstand various forces encountered during operation and maintenance. Load Analysis: The mechanical design of internal components must account for all applicable loads (dead weight, fluid dynamic, thermal, seismic, motion-induced). 6.2 Vessel Design Design Code Compliance: The vessel must be designed, fabricated, inspected, and tested in accordance with an internationally recognized mechanical design code (e.g., ASME Section VIII, Division 1 or 2; PD 5500; EN 13445). Process Designer Input: The process designer provides critical input to the mechanical designer: Maximum and Minimum Operating Pressures: The normal range of pressures during operation. Maximum and Minimum Operating Temperatures: The normal range of temperatures during operation. Maximum and Minimum Design Pressures: These define the pressure boundaries for which the vessel is rated. Maximum Design Pressure: The highest internal pressure the vessel can withstand at the corresponding design temperature. It must be greater than or equal to the maximum operating pressure plus a margin to accommodate pressure-relief device set points and accumulations. Minimum Design Pressure: The lowest internal pressure the vessel can withstand. This is crucial for evaluating external pressure (vacuum) conditions, which can occur during cooldown, steam-out, or depressurization. Maximum and Minimum Design Temperatures: Maximum Design Temperature: The highest temperature the vessel material can safely withstand at the corresponding design pressure. Minimum Design Temperature (MDMT): The lowest temperature the vessel material can safely withstand. This is critical for evaluating brittle fracture risks, especially during depressurization events where Joule-Thomson cooling can lead to very low temperatures. Maximum Liquid Level: The highest possible liquid level (e.g., LSH, or flood level) used for calculating hydrostatic loads. Maximum Liquid Specific Gravity or Density: Used to calculate the maximum hydrostatic pressure exerted by the liquid. Worst-Case Conditions: The process designer must evaluate all potential operating scenarios (normal, start-up, shutdown, transient, maintenance, upset) to identify the true worst-case conditions for pressure and temperature. Example: Rapid depressurization can lead to very low temperatures (MDMT). Example: Steam-out can lead to high temperatures and vacuum conditions. Data Format: Process conditions should be provided clearly as "Pressure @ Temperature" for each design case (e.g., "Condition #1 (Max Flow): $1250 \text{ psig}$ @ $180^\circ F$"). 6.3 Internal Component Design 6.3.1 General Information Transfer: The process designer must provide comprehensive information about fluid properties, flow rates, and functional requirements to the internal component designer. Worst-Case Loads: All applicable operating cases must be evaluated to determine the worst-case mechanical loads on the internals. Load Types: Distributed Loads: (most common) Forces spread over an area, such as pressure drop across a mist eliminator or hydrostatic pressure on a baffle. Point Loads: (less common) Forces concentrated at a single point, such as a heavy instrument supported by a bracket. Dead Loads: Forces due to the weight of the internal components themselves, acting at their center of gravity. Analysis: Mechanical analysis involves calculating reactions, moments, stresses, and deflections for all internal components. Flow Maldistribution: The mechanical design must account for potential flow maldistribution, which can create localized high-velocity zones and increased dynamic loads. CFD & FEA: Simple Geometries: For standard internals and simple geometries, simplified analytical calculations are often sufficient. Complex Geometries/Fluid Distributions: For complex internals, highly turbulent flows, or critical applications, CFD (Computational Fluid Dynamics) can model fluid behavior, and FEA (Finite Element Analysis) can then analyze the resulting stresses and deflections on the internal components. Removable Internals: Internals designed for removal (e.g., for cleaning or inspection) must be extractable through dedicated nozzles or manways without requiring cutting or welding. This implies modular design. Safety: Removable components must meet safety requirements regarding their individual weight for handling during maintenance. 6.3.2 Operational Cases Imposing Mechanical Loads Internal components must be designed to withstand forces generated during all phases of operation. Operating Flow: Forces arise from the movement of single or mixed phases. This includes drag, impingement, and turbulence. All flow rate cases (minimum, maximum, normal) must be considered, as loads can vary with flow. Start-up/Shutdown Flow: During these transient periods, flow rates, pressures, and temperatures can be outside normal ranges. Fluids with different densities/viscosities (e.g., completion fluids, flushing liquids) can introduce unique loading conditions. Trips: Unanticipated events (e.g., emergency shutdowns) can cause rapid changes in flow, pressure, and temperature, leading to sudden and high loads on internals. Slugs: Liquid slugs arriving from upstream (e.g., pipelines) can impose extremely high impact loads on inlet devices and other internals. The magnitude and frequency of slugs must be characterized and included in the design basis. Pressure-relief Valve and Depressurization Events: During relief or depressurization, very high flow rates can occur, potentially causing reverse flow or high velocities through the internals. The load case and direction of forces must be determined. Other Cases: Hot Vapor Bypass: Can lead to thermal shock or high-velocity impingement. Anti-surge Recycling: High-velocity gas recycle can impact internals. Pigging/Scraping: Passing pigs through the vessel (if designed for it) can exert significant forces. Pressure Settle Out: Rapid pressure changes can generate sudden forces. Steam-out: High temperatures and potential for vacuum can stress internals. 6.3.3 Mechanical Loads from Operational Flow Cases (Detailed) Fluid Energy Transfer: Flowing fluids transfer kinetic energy to internal components, resulting in forces. These loads are directly related to fluid properties (mixture density) and velocity. Solids/Fouling: If solids or fouling material are present, they can partially block flow paths, leading to higher localized velocities and increased pressure drops, thus higher mechanical loads. Common Load Types: Differential Pressure Loads: These loads result from the pressure drop across internals that obstruct flow (e.g., mesh pads, vane packs, cyclone decks, perforated baffles). The force is calculated as $\Delta P \times A_{projected}$. Hydrostatic Pressure Loads: Applied by liquids retained by baffles, weirs, or buckets. The force increases with the liquid height. The worst-case hydrostatic load often occurs during hydrotesting of the vessel, where the vessel is filled with water. Momentum Loads: Occur when the direction or velocity of a fluid stream changes. These are particularly significant for inlet devices where the incoming fluid's momentum is dissipated. The force is calculated using Newton's second law, $F = \dot{m} \Delta V$, where $\dot{m}$ is mass flow rate and $\Delta V$ is the change in velocity vector. 6.3.4 Other Mechanical Load Cases Dead Load: The weight of the internal components themselves, including any retained liquid or solids. Maintenance Loads: Internals may be designed to support scaffolding, maintenance personnel, or tools during inspection and repair. Postweld Heat Treatment (PWHT): If PWHT is performed, differential expansion between dissimilar materials (e.g., a stainless steel internal attached to a carbon steel vessel) can induce stresses. Thermal Expansion: Differential thermal expansion between the pressure boundary (vessel shell) and internal components during heating/cooling cycles must be accommodated to prevent buckling or excessive stress. Transportation, Lifting, Handling, Erection, Installation Loads: Internal components must be adequately braced and supported to withstand dynamic loads encountered during these phases. Unexpected loads can be significant. Floating Oil Production Facilities: Vessels on FPSOs, FLNGs, or spar platforms experience cyclic movements (roll, pitch, heave) due to wave and wind action. This causes "sloshing" of liquids, generating high dynamic loads on internal baffles, weirs, and supports. Fatigue analysis is often required for internal components due to these cyclic loads. CFD and FEA are strongly advised to accurately model these complex dynamic loads and their effects (Annex C). Flow-Induced Phenomena: Lift and Drag: Forces exerted by fluid flow on components. Flow-Induced Vibrations (FIV): Can occur when fluid flow excites natural frequencies of internal components, leading to resonant vibrations. This can cause rapid fatigue failure. Mitigation: Loads can be estimated via analytical calculations, CFD, or based on engineering experience. For critical applications, detailed FIV analysis is performed. The process designer must inform the mechanical designer of potential FIV risks. 6.3.5 Minimum Material Thickness Structural Integrity: Internal components must have sufficient thickness to prevent failure under the worst-case loading conditions. Minimum Thickness Rule: For structural components like clips, baffles, support rings, tube sheets, and vane/cyclone boxing, the minimum thickness is the greater of: The calculated thickness required for strength, plus the specified corrosion allowance. A minimum practical thickness, typically $6 \text{ mm}$ ($1/4 \text{ inch}$), to ensure mechanical robustness and ease of fabrication. 6.3.6 Corrosion Allowance Application: Corrosion allowance is added to the calculated thickness of components made from materials susceptible to corrosion in the process environment. Exposure: Internal components exposed on only one side to the corrosive medium (e.g., a baffle contacting liquid on one side, gas on the other): 1x the specified corrosion allowance. All other cases (e.g., components fully immersed, or exposed to both phases, or where corrosion can occur from both sides): 2x the specified corrosion allowance. Specification: The corrosion allowance is typically specified by the company and applied to all wetted surfaces. Removable vs. Non-removable: Non-removable internals: Generally require the same corrosion allowance as the vessel shell. Removable internals: May have a different corrosion allowance, consistent with their expected lifespan and replacement schedule. Welds: Corrosion allowance must also be considered for weld joints. Structural Members: For stress calculations, the fully corroded section properties of structural members should be used. Corrosion Traps: Baffles, partitions, and stiffeners must be designed to avoid trapping fluids or creating crevices where corrosion can accelerate. 6.3.7 Materials of Construction Specification: Materials are typically specified by the company based on process fluid compatibility, operating conditions (temperature, pressure), and expected corrosion mechanisms. Default: If not specified, materials must be compatible with process fluids and operating conditions for the design life of the vessel. Corrosion-Resistant Materials: Often preferred for removable internals, especially those that are difficult to inspect or replace. Wear Pads: Pressure-retaining parts subject to mechanical or adhesive wear (e.g., from solids) should be fitted with wear pads made from more resistant materials. 6.3.8 Welding Full Thickness Welds: Internal components welded to pressure-retaining parts (e.g., vessel shell) should utilize full thickness welds to ensure structural integrity and prevent stress concentrations. Weld Sizing: Weld sizes must be sufficient to withstand all anticipated loads (static, dynamic, thermal). Dissimilar Materials: When welding dissimilar materials, mounting pads made of the vessel material (e.g., carbon steel) are often used to attach stainless steel internals, preventing degradation during welding and mitigating galvanic corrosion. 6.3.9 Bolting of Internal Components Design Criteria: The design criteria and extent of stress calculations for internal bolting should be agreed upon with the company. Double-Nutted: Internal bolting should be double-nutted to prevent loosening due to vibration or thermal cycling. Thread Protrusion: Bolts should protrude by no more than two turns of thread beyond the nut to minimize crevice corrosion and maintain integrity. Minimum Bolt Size: A minimum bolt size of M10 (or equivalent, e.g., $3/8 \text{ inch}$) is typically specified for robustness. Stainless Steel Bolting: For stainless steel bolting, different hardness grades for studs/bolts and nuts are often specified to reduce galling (cold welding). 6.3.10 Gaskets for Internal Components Material Specification: The company specifies gasket materials based on fluid compatibility, temperature, pressure, and susceptibility to explosive decompression (for elastomeric gaskets in high-pressure gas service). 6.3.11 Galvanic Corrosion Prevention Electrical Insulation: When dissimilar metals are joined (e.g., stainless steel internals in a carbon steel vessel), electrical insulation gaskets, sleeves, and washers for all bolting are used to prevent galvanic corrosion. Welded Dissimilar Materials: For welded dissimilar materials, consult the company's metallurgy specialists for specific requirements and mitigation strategies. 6.3.12 Access for Inspection and Maintenance Inspectability: Internals must be designed to allow full visual inspection with minimal dismantling. This includes clear sightlines. Access: Adequate access to critical areas (e.g., mist eliminators, inlet devices, liquid-liquid coalescers) must be provided through manways. Internal Aids: Hand grips, brackets, and internal manways/hatches facilitate personnel entry and movement. Personal Access Openings: Minimum diameter of DN600 (24 inches) for manways to allow personnel entry. 6.3.13 Special Considerations Sour Service (H2S), CO2, Wet CO2: The company specifies metallurgical requirements for resistance to sulfide stress cracking (SSC) in H2S service (NACE MR0175/ISO 15156) and CO2 corrosion (NACE MR0103/ISO 17945). Certified Materials: If certified materials are required for pressure-retaining parts, the company specifies if these requirements extend to internal non-pressure-retaining components. Welding of Internals: When welding internals to a pressure vessel with special metallurgical properties, the design, fabrication, installation, and inspection procedures must ensure compliance with all relevant codes and standards to maintain the vessel's integrity. Annex A: Separator Orientation Selection (Horizontal vs. Vertical) The choice between horizontal and vertical separators is a fundamental design decision with significant implications for performance, footprint, and cost. A.1 Horizontal Separators Advantages: Larger Liquid-Gas Interface: Provides more area for gas-liquid disengagement, making them suitable for high liquid-gas ratio streams or foaming liquids where a large surface area is needed for foam breaking. Longer Liquid Residence Time: Provides a longer path for liquid-liquid (oil-water) separation and solids settling due to the extended horizontal flow path. Ideal for three-phase separation. Higher Liquid Capacity: Can handle larger liquid volumes and slugs more effectively due to the larger disengagement area. Easier Internal Access: Typically easier to access and maintain internals through multiple manways along the length. Lower Installation Height: Requires less vertical height, which can be an advantage for structural considerations or onshore plot space. Disadvantages: Larger Footprint: Requires more horizontal plot space. Less Efficient for High GVF: For very high gas-liquid ratios (high GVF), gas velocities can become very high, leading to re-entrainment. Level Control Challenges: Can be more sensitive to level control issues with rapidly fluctuating liquid levels due to the large interface area. Solids Removal: While offering a large collection area, effective solids removal systems (e.g., flushing, inclined bottom) are needed. Typical Applications: Main production separators (two-phase and three-phase). Test separators. Free Water Knockouts (FWKOs). Vessels handling foaming crude or high liquid loads. A.2 Vertical Separators Advantages: Smaller Footprint: Requires less horizontal plot space, making them suitable for offshore platforms or congested onshore areas. More Efficient for High GVF: Gas flows vertically upwards, which is more efficient for separating liquid droplets from a gas-dominant stream. Less Prone to Liquid Sloshing: Less affected by liquid sloshing in offshore applications compared to horizontal vessels. Easier Solids Removal: Solids tend to collect at the conical or dished bottom, which can be easily drained. Simpler Level Control: Liquid levels are less sensitive to fluctuations due to the smaller liquid-gas interface area. Disadvantages: Limited Liquid-Liquid Separation: Less effective for three-phase separation due to the limited horizontal path for liquid-liquid disengagement. Lower Liquid Capacity: Less forgiving for large liquid slugs compared to horizontal vessels. Internal Access: Access to internals can be more challenging, often requiring internal platforms or lifting out internals. Higher Installation Height: Requires more vertical height, which can impact structural design and lifting requirements. Typical Applications: Gas scrubbers (upstream of compressors, dehydration units). Inlet separators for high GVF wells. Flash drums. Compressor suction scrubbers. Annex B: Mist Eliminator Selection and Performance Mist eliminators are crucial for achieving high gas purity by removing fine liquid droplets. Their selection depends on droplet size, liquid loading, pressure drop, and fouling tendency. B.1 Droplet Size Distribution (Figure B.1 - Conceptual Diagram) Figure B.1 would illustrate the typical droplet size ranges handled by different mist eliminator types: Gravity Settling: $>500 \mu m$ (primary separation) Wire Mesh Pads: $3 \mu m$ to $500 \mu m$ (fine mist) Vane Packs: $8 \mu m$ to $500 \mu m$ (medium to coarse mist, higher liquid loads) Cyclones: $3 \mu m$ to $100 \mu m$ (fine mist, high liquid loads, high efficiency) Coalescing Filters: $ B.2 Wire Mesh Pads Principle: Consist of a dense mat of knitted wire or plastic filaments. Gas flows through the pad, and liquid droplets impact the filaments, coalesce, and drain downwards. Performance: High Efficiency: Very effective for removing droplets down to $3-5 \mu m$. Low Pressure Drop: Typically $25-100 \text{ mm}$ water gauge. Low Liquid Loading: Can flood if liquid loading is too high, leading to re-entrainment. Max liquid loading typically $0.1 - 0.2 \text{ lbm liquid / 1000 scf gas}$. Fouling: Prone to fouling by solids, wax, or viscous liquids. Difficult to clean in situ. Turndown: Limited turndown ratio (2:1 to 3:1) as efficiency drops significantly at low gas velocities. Sizing (K-factor): $K_{mesh} = 0.10 - 0.15 \text{ m/s}$ (Souders-Brown). Applications: General purpose gas scrubbers, glycol contactor overheads. B.3 Vane Packs (Vane-type Mist Eliminators) Principle: Consist of closely spaced, corrugated plates (vanes). Gas flows through the tortuous path, and liquid droplets are thrown against the vane surfaces by inertial impaction and centrifugal force, coalesce, and drain. Performance: Medium-High Efficiency: Effective for droplets down to $8-10 \mu m$. Higher Liquid Loading: Can handle significantly higher liquid loads than mesh pads without flooding. Designed for self-draining. Medium Pressure Drop: Typically $50-200 \text{ mm}$ water gauge. Fouling Resistance: Much more resistant to fouling and plugging by solids or viscous liquids due to their open structure. Easier to clean. Turndown: Better turndown ratio (3:1 to 5:1) than mesh pads. Sizing (K-factor): $K_{vane} = 0.15 - 0.25 \text{ m/s}$. Applications: Main production separators, compressor suction scrubbers, heavy oil service, situations with high liquid slugs. B.4 Axial Flow Cyclones (Demister Cyclones) Principle: Gas enters tangentially or through swirl vanes, creating a strong vortex. Centrifugal force throws liquid droplets to the wall, where they coalesce and drain. Clean gas exits axially. Performance: High Efficiency: Very effective for droplets down to $3-5 \mu m$, sometimes even smaller. Very High Liquid Loading: Can handle extremely high liquid loads and solids. High Pressure Drop: Typically $200-1000 \text{ mm}$ water gauge, due to the high velocities required for centrifugal separation. Excellent Fouling Resistance: Self-cleaning due to high velocities. High Turndown: Excellent turndown ratio (up to 10:1 or more) due to modular design where individual cyclones can be turned off or flow redistributed. Compact: Offer high capacity in a small volume. Sizing (K-factor): $K_{cyclone} = 0.25 - 0.40 \text{ m/s}$. Applications: Offshore platforms where space is critical, high-pressure gas streams, services with high liquid content, dirty services, compressor interstage scrubbers. Annex C: Motion Effects on Separator Design (Offshore Facilities) Vessels on floating production facilities (FPSOs, FLNGs, semi-submersibles) experience continuous motion, which significantly impacts separator performance and mechanical integrity. This requires specialized design considerations. C.1 Types of Motion Translational: Heave (up/down), Surge (fore/aft), Sway (port/starboard). Rotational: Roll (side-to-side), Pitch (bow/stern), Yaw (rotational about vertical axis). Dominant Effects: Roll and Pitch are most significant for separators as they cause liquid sloshing and affect effective gravity. C.2 Impact on Separator Performance Liquid Sloshing: Causes waves and turbulence at the gas-liquid interface, leading to increased gas entrainment in liquid and liquid entrainment in gas. Can cause liquid to splash onto mist eliminators prematurely, leading to flooding. Generates dynamic loads on internal baffles, weirs, and supports. Reduced Effective Settling Time: Sloshing reduces the quiescent time required for efficient gravity separation of droplets. Level Control Instability: Liquid levels fluctuate significantly, making accurate level measurement and control challenging, leading to false alarms or trips. Vortexing: Increased likelihood of vortex formation at liquid outlets due to dynamic liquid movement. C.3 Design Considerations for Motion Increased Vessel Size: Larger Diameter/Length: Often required to provide more gas-liquid disengagement area and liquid residence time to compensate for motion effects. Increased Liquid Level Spans: The distance between LSL/LISL and LSH/LIAH must be significantly increased to accommodate wave heights and sloshing without tripping. Internal Baffles and Anti-Slosh Devices: Longitudinal Baffles: In horizontal vessels, these reduce sloshing in the direction of the vessel's axis. Transverse Baffles: Reduce sloshing across the vessel's width. Perforated Baffles: Allow fluid passage while dissipating wave energy. Open area typically $10-20\%$. Wave Breakers: Specialized internals designed to dampen wave motion. Robust Internal Mechanical Design: All internal components (inlet devices, baffles, weirs, mist eliminators, supports) must be designed for dynamic loads from sloshing (pressure surges, impact forces). Fatigue analysis is often required for critical internals due to continuous cyclic loading. Connections to the vessel wall must be strengthened. Bolted connections must be designed to prevent loosening. Specialized Inlet Devices: Inlet devices that effectively dissipate momentum and promote initial separation even under motion are preferred. Level Instrumentation: Stilling Wells/Cages: Required for float, displacer, or DP-type level transmitters to dampen liquid fluctuations. Guided Wave Radar: Often preferred due to its ability to measure effectively in turbulent conditions, though stilling wells may be needed. Nuclear Gauges: Can be used as they are non-contact and measure average density, less affected by surface turbulence. Redundancy: Often employ redundant level instruments and utilize voting logic (e.g., 2 out of 3) for critical trips to prevent spurious shutdowns. Weir Design: Flooded Weirs: Often preferred over overflow weirs for three-phase separators on floating facilities as they are less sensitive to wave action. Higher Weirs: Weirs may need to be higher to maintain separation integrity during vessel motion. CFD and FEA: Advanced modeling techniques are almost always used for critical separators on floating facilities: CFD: To simulate sloshing, wave generation, and fluid dynamics under various motion scenarios. FEA: To analyze the resulting dynamic stresses on internals and the vessel structure. Annex D: Typical Separator Configurations This annex provides conceptual diagrams and descriptions of common separator configurations. D.1 Horizontal Two-Phase Separator (Figure D.1 - Conceptual Diagram) Typically consists of: Inlet Device: (e.g., half-open pipe, deflector, IVD) for bulk separation. Liquid Level: Maintained by a level controller (LC) and control valve on the liquid outlet. Gas Space: Above the liquid, where gas flows horizontally. Mist Eliminator: (e.g., mesh pad, vane pack) at the gas outlet end for fine liquid removal. Gas Outlet: At the top. Liquid Outlet: At the bottom, usually at the opposite end of the inlet, with a vortex breaker. D.2 Horizontal Three-Phase Separator (Figure D.2 - Conceptual Diagram) Similar to two-phase, but with an additional phase separation section: Inlet Device: As above. Oil-Water Interface: Maintained by an interface level controller (LIC) or a weir. Oil Layer: Between the gas and water phases. Water Layer: At the bottom. Weir or Interface Level Controller: To separate oil and water. Oil Outlet: Usually over a weir or controlled by a LIC. Water Outlet: At the bottom, with a vortex breaker, controlled by a LIC. Gas Space & Mist Eliminator: As above. D.3 Vertical Two-Phase Separator (Figure D.3 - Conceptual Diagram) Typically consists of: Inlet Device: (e.g., tangential inlet, deflector) often located halfway up the vessel. Gas Space: Occupies the upper section of the vessel, where gas flows upwards. Mist Eliminator: (e.g., mesh pad, vane pack) located near the top, spanning the full vessel diameter. Gas Outlet: At the very top. Liquid Space: In the lower section, collected liquid flows downwards. Liquid Level: Maintained by an LC. Liquid Outlet: At the bottom, with a vortex breaker. Conical/Dished Bottom: Often used to facilitate liquid and solids drainage. Annex E: Sizing Examples (Illustrative - numerical values are for demonstration) These examples demonstrate the application of key sizing equations. Actual design involves iterative calculations and detailed vendor data. E.1 Example: Gas-Liquid Disengagement Area Sizing (Vertical Scrubber) Problem: Size a vertical gas scrubber for a gas flow rate of $10 \text{ MSm}^3/\text{day}$ at $60 \text{ bara}$ and $40^\circ C$. Liquid carryover is primarily condensate. Use a K-factor of $0.12 \text{ m/s}$ for the gas gravity section. Given Data: Gas Flow Rate ($Q_g$): $10 \text{ MSm}^3/\text{day} = 10 \times 10^6 \text{ Sm}^3 / (24 \times 3600 \text{ s}) = 115.74 \text{ Sm}^3/\text{s}$ Standard Conditions (STP): $15^\circ C$, $1.01325 \text{ bara}$ ($288.15 \text{ K}$, $101325 \text{ Pa}$) Operating Pressure ($P$): $60 \text{ bara} = 6 \times 10^6 \text{ Pa}$ Operating Temperature ($T$): $40^\circ C = 313.15 \text{ K}$ K-factor: $0.12 \text{ m/s}$ Assume ideal gas behavior for simplicity (or use Z-factor if available). Liquid Density ($\rho_l$): $750 \text{ kg/m}^3$ (condensate) Calculations: Gas Density at Operating Conditions ($\rho_g$): $$\rho_g = \rho_{g,STP} \times \frac{P_{op}}{P_{STP}} \times \frac{T_{STP}}{T_{op}}$$ Assume $\rho_{g,STP}$ for methane (approx. $0.717 \text{ kg/Sm}^3$). $$\rho_g = 0.717 \text{ kg/Sm}^3 \times \frac{60 \text{ bara}}{1.01325 \text{ bara}} \times \frac{288.15 \text{ K}}{313.15 \text{ K}} \approx 38.6 \text{ kg/m}^3$$ Volumetric Gas Flow Rate at Operating Conditions ($Q_{g,op}$): $$Q_{g,op} = Q_g \times \frac{P_{STP}}{P_{op}} \times \frac{T_{op}}{T_{STP}}$$ $$Q_{g,op} = 115.74 \text{ Sm}^3/\text{s} \times \frac{1.01325 \text{ bara}}{60 \text{ bara}} \times \frac{313.15 \text{ K}}{288.15 \text{ K}} \approx 2.14 \text{ m}^3/\text{s}$$ Maximum Allowable Gas Velocity ($V_g$): $$V_g = K \sqrt{\frac{\rho_l - \rho_g}{\rho_g}} = 0.12 \sqrt{\frac{750 - 38.6}{38.6}} = 0.12 \sqrt{18.425} \approx 0.12 \times 4.29 \approx 0.515 \text{ m/s}$$ Minimum Required Gas Flow Area ($A_g$): $$A_g = \frac{Q_{g,op}}{V_g} = \frac{2.14 \text{ m}^3/\text{s}}{0.515 \text{ m/s}} \approx 4.15 \text{ m}^2$$ Minimum Vessel Diameter ($D$): For a vertical vessel, $A_g = \frac{\pi D^2}{4}$. $$D = \sqrt{\frac{4 A_g}{\pi}} = \sqrt{\frac{4 \times 4.15}{\pi}} = \sqrt{5.28} \approx 2.30 \text{ m}$$ Therefore, a minimum vessel diameter of approximately $2.30 \text{ m}$ is required for the gas gravity section. E.2 Example: Liquid-Liquid Settling (Horizontal Three-Phase Separator) Problem: Estimate the minimum effective length required for water droplets to settle out of oil in a horizontal three-phase separator. Target droplet size $100 \mu m$. Given Data: Oil Density ($\rho_{oil}$): $800 \text{ kg/m}^3$ Water Density ($\rho_{water}$): $1000 \text{ kg/m}^3$ Oil Viscosity ($\mu_{oil}$): $5 \text{ cP} = 0.005 \text{ kg/(m} \cdot s)$ (continuous phase for water droplets) Water Droplet Diameter ($d_p$): $100 \mu m = 100 \times 10^{-6} \text{ m}$ Vertical Separation Distance ($H_{separation}$): Assume $0.5 \text{ m}$ (from top of oil layer to interface). Bulk Liquid Axial Velocity ($V_B$): $0.02 \text{ m/s}$ (design target) Calculations: Check Reynolds Number for Droplet: $$Re_d = \frac{\rho_{oil} V_T d_p}{\mu_{oil}}$$ We need $V_T$ first, so assume Stokes' Law applies, then verify. Terminal Settling Velocity ($V_T$) (using Stokes' Law): $$V_T = \frac{g d_p^2 (\rho_{water} - \rho_{oil})}{18 \mu_{oil}}$$ $$V_T = \frac{9.81 \times (100 \times 10^{-6})^2 \times (1000 - 800)}{18 \times 0.005}$$ $$V_T = \frac{9.81 \times 10^{-8} \times 200}{0.09} = \frac{1.962 \times 10^{-5}}{0.09} \approx 0.000218 \text{ m/s}$$ Verify Stokes' Law Assumption: $$Re_d = \frac{800 \times 0.000218 \times 100 \times 10^{-6}}{0.005} \approx 0.0035$$ Since $Re_d Minimum Effective Separation Length ($L_{eff}$): $$L_{eff} = H_{separation} \times \frac{V_B}{V_T}$$ $$L_{eff} = 0.5 \text{ m} \times \frac{0.02 \text{ m/s}}{0.000218 \text{ m/s}} \approx 0.5 \times 91.7 \approx 45.85 \text{ m}$$ This calculated length ($45.85 \text{ m}$) is very long for a single separator. This indicates that for $100 \mu m$ droplets in this oil, gravity settling alone in a conventional horizontal vessel might be insufficient without additional internals (e.g., coalescing plates) or a much lower bulk velocity. This highlights the importance of droplet size and fluid properties. Annex F: Process Sizing Data Requirements (Datasheet Format) A comprehensive datasheet ensures all necessary information for separator design is captured. Below is a simplified example of required data points. F.1 General Information Tag Number: Service: P&ID Number: Project Name: Design Code: Location (Onshore/Offshore, Floating/Fixed): F.2 Design Conditions Design Pressure (Min/Max): Design Temperature (Min/Max): Hydrotest Pressure: Corrosion Allowance: External Pressure/Vacuum: F.3 Operating Conditions (for each case: Normal, Max, Min, Transient) Flow Rate (Gas, Oil, Water) (Mass & Volume): Operating Pressure: Operating Temperature: Fluid Composition (Mol% for gas, Wt% for liquids): Fluid Properties (at operating conditions): Gas Density ($\rho_g$): Gas Viscosity ($\mu_g$): Oil Density ($\rho_o$): Oil Viscosity ($\mu_o$): Water Density ($\rho_w$): Water Viscosity ($\mu_w$): Gas-Liquid Interfacial Tension ($\sigma_{gl}$): Oil-Water Interfacial Tension ($\sigma_{ow}$): Foaming Tendency (Yes/No, Severity): Emulsion Tendency (Yes/No, Type, Severity): Solids Content (Type, Size Distribution, Mass Flow Rate): F.4 Separation Requirements Gas Outlet Specification: Max Liquid Carryover (e.g., L/MSm$^3$, mg/L, %): Droplet Cutoff Size ($\mu m$): Max Solids Carryover: Oil Outlet Specification: Max Water in Oil (%): Max Gas in Oil (e.g., ppm, %): Max Solids in Oil: Water Outlet Specification: Max Oil in Water (mg/L, ppm): Max Solids in Water: F.5 Level Control & Instrumentation NLL, LAH, LSH, LAL, LSL (Elevations from BTL/BOV): NIL, LIAH, LISH, LIAL, LISL (Elevations from BTL/BOV): Minimum Liquid Residence Time (total, oil, water): Level Control Type (e.g., float, displacer, radar): Safety System Requirements (e.g., API 14C compliance): F.6 Mechanical Features Vessel Orientation (Horizontal/Vertical): Internals Required (Inlet device type, Mist eliminator type, Baffles, Weirs, Vortex Breakers): Manway/Nozzle Sizes and Locations: Lifting Lugs, Support Type: Insulation/Heat Tracing Requirements: Material Requirements (NACE, etc.): Annex G: Inlet Piping Recommendations The design of the inlet piping leading to the separator significantly influences the flow regime, droplet size distribution, and overall separation efficiency. G.1 Importance of Inlet Piping Flow Regime: The flow regime (e.g., slug, annular, dispersed bubble) in the inlet pipe determines the initial state of the fluid entering the separator. Slug flow can cause high impact loads and operational upsets. Droplet Size: High velocities and turbulence in the inlet pipe can shatter larger liquid droplets into finer mist, making them harder to separate. Conversely, low velocities might allow for some pre-coalescence. Momentum: The momentum of the incoming stream must be dissipated effectively by the inlet device to prevent re-entrainment and turbulence. G.2 Recommended Configurations Straight Run: Provide a sufficient length of straight pipe upstream of the inlet nozzle to establish a relatively stable flow profile. Minimum 10-20 pipe diameters of straight run is recommended, especially if there are bends or valves upstream. Longer straight runs (e.g., 30-50D) are beneficial for mitigating slug flow effects, allowing slugs to stabilize or disperse. Gradual Transitions: If the inlet pipe diameter changes to match the nozzle, use gradual reducers or expanders (e.g., conical sections with small cone angles, $7^\circ$ included angle max) to minimize turbulence. Avoid Sharp Bends: Avoid sharp 90-degree elbows immediately upstream of the separator inlet, as these create highly turbulent flow and can shatter droplets. Use long-radius elbows if bends are unavoidable. Inlet Nozzle Orientation: Horizontal Vessels: Inlet nozzle typically enters through the head (preferred) or the shell near one end. Vertical Vessels: Tangential inlets are common to induce swirl, or radial inlets with an internal deflector. G.3 Slug Flow Mitigation Slug Catcher: For severe slugging conditions, a dedicated slug catcher upstream of the separator may be required to handle large liquid volumes. Inlet Device Selection: Inlet devices like cyclonic inlets or IVDs are more effective at handling slug flows than simple deflectors. Line Sizing: Inlet lines should be sized to avoid severe slugging regimes where possible. Consider multi-phase flow correlations. Annex H: Droplet Settling/Rising Models and Ballistic Model Understanding how droplets settle or rise is fundamental to sizing the gravity separation sections. H.1 Droplet Settling/Rising Velocity ($V_T$) The terminal velocity of a droplet depends on its size, the densities of the dispersed and continuous phases, and the viscosity of the continuous phase. The Reynolds number of the droplet ($Re_d = \rho_c V_T d_p / \mu_c$) determines which flow regime (and thus which equation) applies. Stokes' Law Regime ($Re_d For very small droplets where viscous forces dominate. $$V_T = \frac{g d_p^2 (\rho_p - \rho_c)}{18 \mu_c}$$ Where: $g$: gravitational acceleration ($9.81 \text{ m/s}^2$) $d_p$: droplet diameter ($m$) $\rho_p$: density of dispersed phase ($kg/m^3$) $\rho_c$: density of continuous phase ($kg/m^3$) $\mu_c$: dynamic viscosity of continuous phase ($Pa \cdot s$ or $kg/(m \cdot s)$) Intermediate Law Regime ($0.2 For medium-sized droplets where both viscous and inertial forces are significant. This is often an iterative solution or an empirical correlation is used. A common approximation is: $$V_T = \frac{g^{0.71} d_p^{1.14} (\rho_p - \rho_c)^{0.71}}{\rho_c^{0.29} \mu_c^{0.43}}$$ Newton's Law Regime ($Re_d > 500$): For larger droplets where inertial forces dominate. $$V_T = \sqrt{\frac{4 g d_p (\rho_p - \rho_c)}{3 C_D \rho_c}}$$ Where $C_D$ is the drag coefficient, typically $0.44$ for spherical droplets (though it can vary). Procedure: Assume Stokes' Law and calculate $V_T$. Calculate $Re_d$ using this $V_T$. If $Re_d If $0.2 If $Re_d > 500$, use Newton's Law. H.2 Effective Separation Length ($L_{eff}$) For a horizontal flow path, the minimum effective length required for a droplet to separate is: $$L_{eff} = H_{separation} \times \frac{V_{horizontal}}{V_T}$$ Where: $H_{separation}$: Vertical distance the droplet must travel (e.g., from top of oil layer to interface, or from gas space ceiling to liquid surface). $V_{horizontal}$: Average horizontal velocity of the continuous phase (e.g., bulk liquid axial velocity $V_B$ or gas velocity $V_g$). H.3 Ballistic Model (for Gas Carryover) The ballistic model helps estimate the maximum droplet size that can be carried horizontally by the gas stream without settling, particularly relevant for the gas gravity section. Considers the horizontal velocity of the gas ($V_g$) and the vertical settling velocity of the droplet ($V_T$). A droplet starting at the top of the gas space must settle a vertical distance (H) while being carried horizontally by the gas. Time to settle ($t_{settle}$) = $H / V_T$. Horizontal distance carried ($L_{carry}$) = $V_g \times t_{settle} = V_g \times (H / V_T)$. If $L_{carry}$ is less than the effective horizontal gas path length, the droplet settles. If greater, it is carried over. This model is often used to determine the maximum allowable gas velocity or the minimum height of the gas space for a desired droplet cut-off. Annex I: Self-Venting Liquid Outlet Nozzles/Drainage Pipes Self-venting design prevents vapor lock or two-phase flow in liquid outlet lines, which can lead to unstable level control, cavitation in pumps, or reduced flow capacity. I.1 Principle Ensures that any gas entrained in the liquid or flashing in the outlet line can freely escape back into the vessel's gas space, allowing only liquid to flow out. This is achieved by maintaining a sufficient liquid head above the outlet nozzle and ensuring the outlet line geometry allows for gas disengagement. I.2 Design Considerations Submergence: The liquid outlet nozzle must be adequately submerged below the LSL/LISL to provide a sufficient liquid head. This head prevents gas from being drawn into the nozzle due to pressure differences. Vortex Breaker: A vortex breaker is crucial to prevent gas entrainment via vortex formation. Downward Slope: The liquid outlet piping immediately downstream of the vessel should have a continuous downward slope to facilitate liquid drainage and prevent gas holdup. No Siphons/U-bends: Avoid any piping configurations that create siphons or U-bends where gas could accumulate and form a vapor lock. Line Sizing: Size the outlet line to ensure liquid velocities are low enough to allow any entrained gas bubbles to rise and disengage back into the vessel. Typically, liquid velocities are limited to $1 \text{ m/s}$ (or lower for critical services). Vent Connection: In some cases, a small vent line from the highest point of the outlet piping back to the vessel's gas space may be installed, although a truly self-venting design aims to avoid the need for this. Application to Mist Eliminator Drainage: The same principles apply to mist eliminator drainage pipes. They must be submerged in the bulk liquid and designed to allow collected liquid to drain freely without gas blockage. Annex J: Interface Entrainment in Gas Gravity Section High gas velocities in the gas gravity section can generate turbulence at the gas-liquid interface, leading to the re-entrainment of liquid droplets into the gas phase. J.1 Mechanism Shear Stress: The upward flowing gas exerts shear stress on the liquid surface. Wave Formation: At critical gas velocities, waves form on the liquid surface. Droplet Generation: If the gas velocity is sufficiently high, these waves can become unstable, and gas shear can tear off liquid droplets from the wave crests, re-entraining them into the gas stream. This phenomenon is often referred to as "liquid carryover by shear" or "gas-induced entrainment." J.2 Factors Influencing Interface Entrainment Gas Velocity: The primary factor. Higher velocities increase shear stress. Gas Density: Higher gas density increases momentum and shear. Liquid Density: Lighter liquids are more easily entrained. Interfacial Tension: Lower interfacial tension makes the liquid surface more susceptible to droplet formation. Liquid Viscosity: Higher viscosity can dampen wave formation but can also lead to larger, more stable droplets once entrained. Foaming: Foam at the interface significantly exacerbates entrainment. Vessel Motion: Sloshing on floating facilities greatly increases interface turbulence and entrainment. J.3 Mitigation and Design Limits K-factor Limitation: The K-factor used for sizing the gas gravity section inherently accounts for interface entrainment to some extent. However, specific limits may be applied. Gas Velocity Limit: A common rule of thumb for gas velocity at the interface to prevent excessive entrainment is: $$V_g Interface Baffles: Horizontal perforated baffles or anti-slosh baffles can be installed just above the NLL to suppress wave formation and reduce turbulence at the interface. Anti-Foam Agents: If foaming is the primary cause of interface entrainment, chemical anti-foam injection can be effective. Increased Gas Space: A larger gas space (larger diameter or height in vertical vessels) provides more residence time for entrained droplets to settle back down.